Is it possible to make an electric boiler with your own hands: rules for assembling a homemade boiler

Heating your home with electricity — the most technologically advanced option. Electrical energy is converted into heat energy without losses and is conveniently and cheaply transported.

There are a number of standard solutions for organizing heating - heat pumps, reverse air conditioners, ceramic infrared radiators, convectors, electric boilers. Installation of an electric boiler is popular.

Content

Electric boiler for home heating

Advantages of installing a central electric heater:

- Application other types of fuel in parallel with electricity.

- Possibility to embed in an existing heating system.

- Saving on heaters.

- Simplicity design and maintainability.

- Saving in the presence of differentiated tariffs for heating.

- Low cost of equipment, possibility of remote control.

- Availability technologies, the ability to assemble a heater with your own hands.

- Possibility of installation in the heating system private house and outbuildings.

- The optimal solution in the presence of alternative energy sources: solar panel or wind generator.

Electric boiler device

There are different methods of implementing an electric boiler, but any one contains three components:

- Heater.

- Frame.

- Management and Security Group.

The differences between electric boilers are usually variations of these parameters and options.

How it works

The device is connected to liquid heating system. The system is filled with a coolant, which is heated by a heating element. A pump or gravity constantly forces the liquid to circulate.

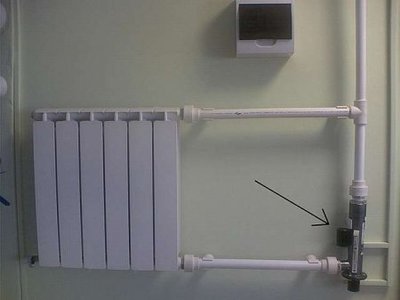

The liquid gives off heat to the room through heat exchangers - batteries. The cold liquid is fed back to the boiler.

Throughout highways or sensors are installed at certain points in the room. They send a signal to the controller, which reduces or increases the voltage or switches off the boiler.

Electric boiler control depending on connection diagrams and the components used are stepped or smooth.

The selection of heater power depends on the size of the heater tank and the power of the radiators. Installing heaters that are too powerful can cause the coolant to boil and the system to rupture.

Attention! For increased safety, use the maximum mechanical thermostat with relay, which will prevent the liquid from boiling if the controller electronics fail.

Network connection and control unit

To connect securely to the network you will need:

- Wires of the appropriate cross-section. The cross-section is calculated based on the power and length, for a powerful system it is better to connect a power cable and 380 volts.

- Grounding: metal parts should be connected to the grounding circuit.

- Separate differential circuit breaker — will turn off the consumer if the protective tube rusts and “breaks through” into the house.

To regulate the current strength, purchase:

- Controller or control unit.

- Ammeter.

- GPS module.

- Mechanical valve, which turns off the electricity when the liquid in the boiler boils (a reliable mechanism, operated by pressure).

Homemade Electric Boiler Schemes

A home craftsman can easily assemble an electric heater in his own home workshopThere are a number of schemes and solutions that are optimal for different conditions.

From a cast iron battery with a heating element

If you plan to heat a small insulated room (a utility room, garage, isolated room), a cheap option would be to convert cast iron battery into an electric heater. This option serves as an electric boiler and heat exchanger.

For assembly you will need:

- Cast iron battery. The length of the battery is selected based on the heat loss of the room. One standard rib is capable of releasing 0.1-0.2 kW/h.

-

heating element must be liquid, with the possibility of a hermetic threaded connection. The length of the heater, if possible, is the length of the battery - then you will achieve maximum efficiency.

The heating element power is less than the heat transfer capacity of the battery - you can not use a regulator.

- Power regulator. PWM will handle low power, if there are several batteries, you can purchase a multi-band controller.

- Electrical wires the required cross-section.

The heating element is installed in the lower plug of the battery. If the battery is insulated, the opposite plugs are plugged, and above the heating element, a additional expansion tank, which also serves as a “watering can” for filling and bleeding the battery.

If the battery will serve as an electric boiler, the cold water supply is connected to the opposite side of the battery at the bottom, and the cold water intake is connected to the top of the battery.

When installing, we always apply the rules for safe installation of electrical wiring.

Attention! With a small cross-section of wires, uninsulated twists or weak contacts, there is fire risk.

From the pipe

There are the following types of electric boilers made from pipes.

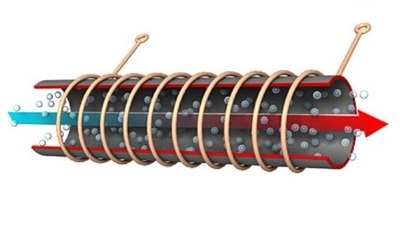

Induction

Works on the principle of electromagnetic induction.

The plastic pipe is placed inside metal pin.

A spiral of thick copper wire is wound through the dielectric on top.

Direct current is supplied to the wire, the core heats up and transfers the temperature to the flowing coolant.

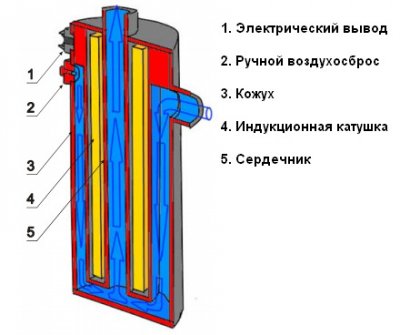

With thermal electric heaters

The simplest boiler can be assembled from a thick-walled metal pipe or a 10-kilogram fire extinguisher. The heater in this system is a regular heating element. It consists of a heating nichrome spiral immersed in a heat-transfer core and a waterproofing shell. The heating element, in essence, household boiler.

The heating element is installed both at the bottom and at the top of the tank. The heating coils are easily inserted and removed without welding, since the service life heating coils limited, they will need to be changed periodically. The heating thread heats up when current passes through it and heats the water.

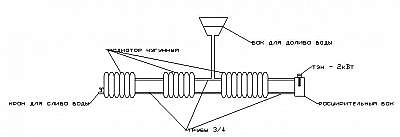

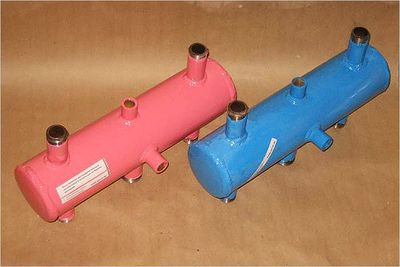

If more power is required, you can assemble flow-through combination boiler from several blocks connected by jumpers.

Electrode boiler

The essence of the operation of an electrode boiler - the principle electrolysis. The boiler consists of a tube - a body, into which a metal pin is lowered through a dielectric gasket. The body is connected to the "zero" phase and grounded.

On one side of the body is the supply of cold water, on the other is the outlet of heated water. An important element is the heat carrier, certain additives are added to it.

The water is heated by movement of electrons between the anode and cathode.

Do-it-yourself electrode boiler carries potential danger. The heating system in this case is an element of the electric circuit. If the ground wire is damaged for some reason, the system becomes dangerous - if you touch the body, you can get an electric shock.

DIY

The construction of the boiler consists of two stages - design and assembly.

Design and preparation of drawings

At the design stage, the following is determined:

- Type of boiler. The difference in boiler efficiency is small, so it is better to choose a heating element system that has been tested over the years.

- Boiler power. It is determined by the sum of the heaters’ capacities and depends on the heat loss of the room, as well as the thermal capacity of the batteries.

- General scheme and draw a project.

Assembly

The assembly consists of several stages.

Search and preparation

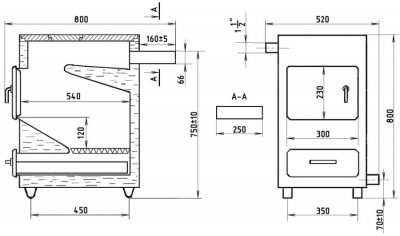

For our design we will need pipe cutting 150 mm in diameter, two plugs, electric heaters, fittings for the inlet/outlet of the coolant, connection of heaters and air bleed valve.

Materials processing

Pipe required hermetically sealed weld, connect the fittings. For this, we turn to familiar welders. The task is easier if you have a fire extinguisher body - it is made of corrosion-resistant steel, the thickness and dimensions are quite suitable. All that remains is to weld threaded connections.

Final assembly

To assemble an electric boiler, we will need:

- Tools: adjustable and open-end plumbing wrenches, a screwdriver and an electricity indicator.

- Consumables: sealing gaskets, flax tow or fum tape.

The assembly proceeds in logical stages:

- Attaching heating elements to the housingIt is desirable that they are located at the bottom - this way the heating will be more uniform.

- Wall mounting. For this purpose, mounting brackets are welded in advance. You can use tension clamps.

- Connection to the heating systemAll connections must be with taps - this will make it easier to remove the electric boiler in case of repair.

- Connecting electrical wires to the heating element contacts. It is better to connect through a power regulator.

- Necessarily ground the housing. This will prevent electric shock in the event of a breakdown of the heater insulation.

Trials

The boiler starts only on filled heating system. When checking, special attention should be paid to the integrity of the contacts, the presence of an electrical "breakdown". For this, you will need an indicator. If the indicator light glows when connecting the wires, turn off the device and check where the current leak occurred.

Difficulties in construction

The design of the electric boiler is simple and it is difficult to make mistakes. The main thing is to select a complete heating element that will be the same size as the body. All welded joints must be performed professional, otherwise leaks are possible.

It is better to seal the joints with flax tow and a special paste. Winding too much flax can damage the connections.

For safe operation of the boiler, a limit thermostat is built into the system - when the coolant reaches a high temperature, this device switches off the heating element.

For more efficient operation, the electric boiler is insulated by placing it in insulated foam plastic body.

Homemade with heating elements or factory-made

If desired, purchase a factory-made electric boiler. However, it is worth understanding that a homemade design will come out cheaper with the same efficiency, various control variations can be connected to a homemade boiler, and the piping can be supplemented with new units. This option will not be available in a finished factory product.

Photo 1. Single-circuit electric wall-mounted boiler, model EVPM-Next, manufacturer - "ERDO", Russia.

A properly functioning electric boiler optimally copes with heating the house and prevents power outages on the batteries.

The design and implementation of complex and obscure connection schemes is carried out under under the supervision of experienced specialists.

Do not boil the liquid in the boiler, heat it up uniform and constant. Low-temperature systems are preferred - they are safer and more controllable. If there are temperature jumps, replace the heater and regulator.

Useful video

Check out the video that shows you how to make an electric boiler yourself.

Conclusion

Electric boiler - comfortable and technological type of heating. It requires virtually no repairs or maintenance and can operate for a long time.