Reliable and highly productive device. Do-it-yourself induction heating boiler: features, diagram

An induction heating boiler made by yourself is a profitable option that will help you heat economically private house, apartment or non-residential building.

Such devices have high productivity and simple design. The operating principle of this system based on induction electricity.

The advantages of the heating device are the elements included in its composition, which are capable of withstanding heavy loads. The risks of rapid breakdowns of the heating boiler are minimal. Also, in the project of the considered device there are no detachable connections, which guarantees the absence of leaks. The heating boiler, made with your own hands, functions silently, which makes it possible to install it in a convenient place.

Content

Induction boiler device for heating a private house

The equipment is intended for converting electrical energy into heat energy using the device.

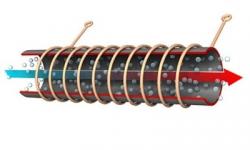

Induction units are capable of rapidly increasing temperature coolant, unlike heating elements. An important part of the device is the transformer (inductor), which consists of two types of winding.

A current is generated inside, which has a vortex type, then the energy is supplied to the short-circuited turn, which also serves as a housing. When the secondary winding receives a sufficient amount of energy, which is instantly converted into heat, which heats the coolant.

Inductor

This element is an important component of the device in which an alternating magnetic field appears, the device consists of two types of winding — primary and secondary. It is made of stainless steel wire on a plastic body. This method increases the efficiency and productivity of the unit. To make the body of the device, you will need a thick plastic pipe 5 centimeters in diameterIt will serve as the base of the induction coil and will be part of the heat conductor.

Inverter

This component takes household electricity and converts it into high frequency current. After which the energy is supplied to the primary winding of the inductor.

Heating element

For preparation you will need: two metal pipes, which have a diameter 2.5 cm. The products should be welded together, making the part round. The mechanism will serve not only as a heating element, but also as a boiler core.

Photo 1. Induction boiler, made by hand. The heating element is located inside the structure.

Branch pipes

One branch pipe serves forfor the coolant to enter the boiler, second to supply heated water to the heating system.

Reference. The principle of calculating the inductor depends on the required boiler power for heating the room. Calculation formula: 1 kW per 10 square meters area of the premises, with ceiling heights not exceeding three meters. For example, a room with a total area 160 m2 heat induction boiler with power 16 kW.

The mechanism of operation of heating from an induction cooker

Design the boiler is based on electric inductors, which include 2 windings short-circuited. The internal winding converts the incoming electrical energy into eddy currents. An electric field is generated inside the unit, which then enters the second turn.

The secondary element functions as a heating element. heating unit and boiler body.

Transfers the generated energy on the coolant of the heating system. Special oil, purified water or antifreeze are used as heat carriers for such boilers.

The internal winding of the heater is exposed to electric energy, which causes voltage and eddy currents to appear. The energy received is transferred to the secondary winding, after which the core is heated. When the entire surface of the coolant has been heated, It will transfer the heat flow to the radiators.

How to make the device yourself

You can make an induction boiler yourself, the main thing is to follow the instructions below.

Necessary tools and materials

- Wire cutters, pliers.

- Circulation pump.

- Inverter welding.

- Ball valves and adapters will be required when installing the unit to the heating system.

- Copper, steel or stainless steel wire. It is better to buy new materials, since it is better not to use the winding from old coils. The cross-section of the wire that is suitable for winding the pipe is 0.2 mm, 0.8 mm, 3 mm.

- A piece of plastic pipe - frame constructions.

Work execution procedure

To assemble a simple induction boiler, you will not need to use complex tools or expensive materials.

All you need is an inverted welding machine. Basic and step-by-step stages of production:

- Cut steel or stainless steel wire into pieces using wire cutters from 5 to 7 cm.

- Plastic pipe for assembling the body of the device with a diameter of 5 cm. The pipe should be tightly filled with cut pieces of wire and laid out so that there is no empty space inside.

- A fine-grained metal mesh is attached to the end parts of the pipe.

- Short sections of pipe are attached to the bottom and top of the main pipe.

- Wrap the pipe tightly with copper wire, the number of turns not less than 90. The same distance should be maintained between the turns.

Important! All exposed sections of copper wire should be insulated with special materials that have good electrical and thermal conductivity. Induction boiler requires mandatory grounding.

- Special adapters are connected to the body of the heater, designed for insertion into heating or plumbing structures.

- A circulation pump is installed.

- An inverting element is connected to the finished coil. for 18-25 A.

- The heating system is ready to be filled with coolant.

Attention! Do not start the heating boiler if there is no coolant in the structure. Otherwise the plastic material of the case will begin to melt.

The result is an inexpensive, simple unit that will effectively heat the serviced premises.

A heating system is suitable for installing an induction system. Closed type design with pump, which will create circulation of water in the pipeline.

Pipes made of plastic are also suitable for installation work when connecting a homemade heating device.

When installing, it is imperative to maintain a distance from nearby objects. According to safety regulations, there must be a distance from the heating unit to other objects and walls about 30 cm and more, from the floor and ceiling 80 cm and moreIt is recommended to install a device for measuring the liquid pressure in a closed space and a manual air vent at the outlet pipe.

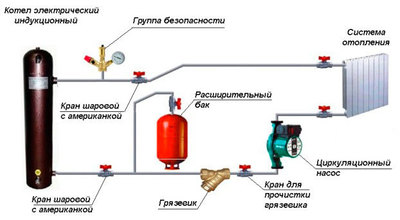

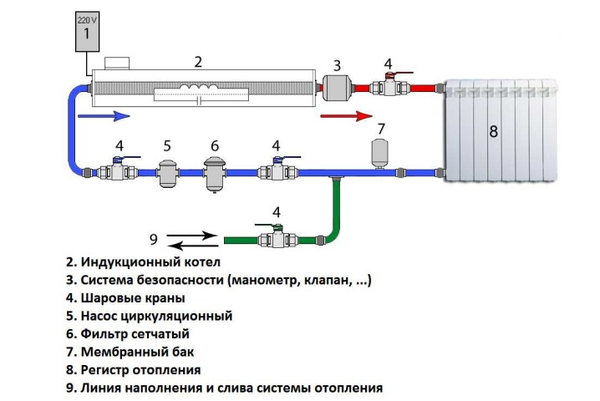

How to connect a boiler with your own hands, diagram

- DC power supply 220 V.

- Induction boiler.

- Group of safety elements (device for measuring pressure liquids, air vent).

- Ball valve.

- Circulation pump.

- Mesh filter.

- Membrane tank for water supply.

- Radiator.

- Heating system fill and drain line indicator.

Photo 2. Induction boiler connection diagram to the heating system. The numbers indicate the parts of the structure.

Useful video

Watch the video, which tells you how to make an induction heating boiler yourself.

The main arguments in favor of this technology

The main advantage of making an induction boiler yourself is that ease of installation, which is produced in any convenient place, a separate room is not required. For example, a part of the pipe located close to the radiator inlet is cut out, and a heating device is attached. It is quite difficult to make an induction heating unit with your own hands, but savings in operation and no need for additional maintenance are advantageous design qualities.

Comments