Comfortable temperature and hot water are the merit of an electric boiler and an indirect heating boiler

A boiler is a device intended for heating water, the second name of the device is water heater. The device is used when it is necessary to provide a residential building with hot water.

Types of indirect heating boilers

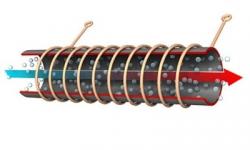

Similar device functions only in conjunction with external heating sources. The heat carrier is supplied from the device. The water inside is heated due to the circulation of the liquid.

To reduce heat loss, a polyurethane coating is used. Cold water enters the tank through special pipes. Indirect heating boilers are divided into:

- Wall mounted

Similar devices are located at a certain distance above the floor. They are compact and have limited capacity. A solid wall should be selected for their placement. The base is the body that contains the boiler system. The heat-insulating layer is laid between the outer wall and the water tank.

The design includes heat exchanger, ensuring uniform heating of the liquid inside the tank. Thermometer is designed to control water temperature. It is used as corrosion protection magnesium anode.

- Floor standing

Devices have large dimensions and are used in industry. A separate room is selected for their installation. The devices consist of an enamel tank, a control thermostat, a magnesium anode, a high-density heat-insulating layer, a heat exchanger and a heating element. In such devices, heat exchange occurs with greater efficiency, due to the increased diameter of the coil.

- Vertical

They are the most common variety. Their use allows you to save space. Reduced dimensions negatively affect the capacity of the tank and productivity. Such a device is suitable for installation in a private house or office building.

Photo 1. Indirect heating boiler of vertical type, connected to a heating system with an electric boiler.

The outer casing is made of corrosion-resistant materials such as enameled, stainless steel or plastic. The heat exchanger coil is manufactured made of brass and has a complex shape, which allows for more efficient heating of the coolant. The design also includes thermal insulation, a reservoir, anode, and thermostat.

- Horizontal

Such devices more capacious and often used in various enterprises. The use of such devices eliminates the need to install additional pumps. The heat exchanger has a spiral shape. Water supplied from the boiler circulates through it. It is often made of carbon steel or brass. When used in production, the device is connected to the water supply system.

This type of boiler is popular due to the absence of expenses associated with its operation. The device does not burden electrical wiring and helps save money.

The closed circuit allows the consumer to receive hot water when opening the tap without first draining the cold sludge.

The design includes a horizontally located tank, a layer of thermal insulation, an anode and a thermometer.

Each type of boiler has its own characteristics, as well as positive and negative sides. All devices combines the general operating principle and basic elements, included in the structure.

Important! Regardless of the type of device, water is never supplied from the heating boiler directly to the tank. used as a heat carrier, located in the heat exchanger. Heating is carried out gradually due to the contact of water with the walls in the tank, which are in contact with the coil.

How to choose the right boiler with an electric boiler?

The device is used in various fields and has certain features depending on the area of use. When purchasing a boiler, pay special attention to:

- Volumes of hot water consumption

The higher this figure, the greater the capacity of the tank should be.

It is necessary to accurately calculate the number of consumers and select the required volume, for example, if we are talking about servicing three people, then the tank per 100 liters will be quite enough.

When a boiler needs to be installed in a summer house or a private home needs to be equipped with it, you can save money and purchase a unit with a tank for 80 liters.

- Consumer lifestyle

If the device is installed in an office building or a residential building, it must have high power ratings to ensure an uninterrupted supply of hot water. When installing in a summer house or private home high power is redundant, since in these conditions there are not a large number of consumers, and there is no need to ensure an uninterrupted supply of hot liquid.

- Coolant flow rate through the circuit

A large area of the coil will increase the speed of heating the water in the tank and increase the consumption of the coolant coming from the electric boiler. This will require additional electricity costs. If there is no need for rapid heating, then you can avoid large expenses. Thus, a heat exchanger with a total area of 1 square meter heats up 120 liters in the tank in 30 minutes. You can also save on the material from which the coil is made.

- Tank body

It must be produced. made of durable anti-corrosion material. Steel and stainless steel are considered the most reliable in this regard. Particular attention should be paid to the internal coating of the device. If ceramics or glass ceramics are used as the lining, then you can be sure of the durability of the product.

- Thermal insulation

Often used as a layer between the outer casing and the water tank ordinary foam rubber.

Photo 2. Internal structure of an indirect heating boiler. Thermal insulation is shown in yellow.

This measure makes the device less expensive, but reduces its efficiency, increasing heat loss. Most of the energy intended for heating water goes to waste, and the efficiency of the device decreases. In modern models, thermal insulation is used polyurethane.

This material is capable of storing a large amount of heat and heating the outer walls of the tank, ensuring the most efficient transfer of energy from the coil to the reservoir.

Reference. Taking into account the factors described, you can choose the ideal indirect heating boiler with an electric boiler. Smart purchase will allow to satisfy the needs of consumers in full and save some money.

Connection diagrams

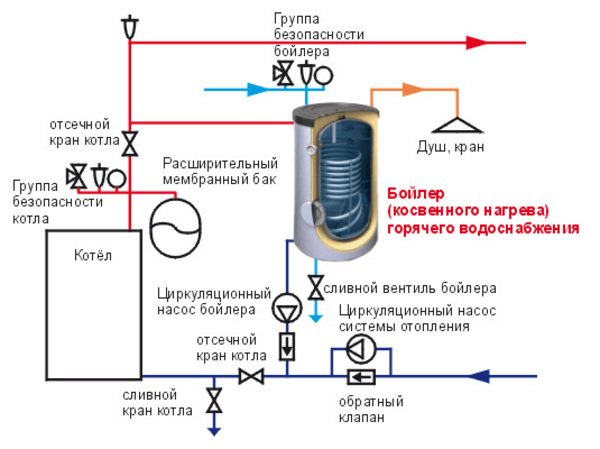

To ensure stable operation of each device in the system, it is necessary to install a tank designed for hot water at the outlet of the boiler. Its volume should be 10% of the main tank capacity. Such a measure will help neutralize thermal expansion.

Do not neglect the installation of shut-off valves in each branch. This will allow you to quickly disconnect the faulty device from the system and carry out repairs. Check valves should be installed on the supply pipes to prevent backflow. There are many connection methods, each with its own characteristics:

- Two-pump system

It includes two pumps, one of which refers to the boiler itself, another - to the heating system.

Photo 3. Two-pump boiler connection diagram. In it, one pump is related to the boiler, the other to the heating system.

One of these devices can be mounted on both the supply and return pipes. Such a scheme does not provide for a three-way valve. The connection is made using ordinary tees. The flow of hot water from the boiler is regulated by turning the pumps on and off.

The system is automated, and stopping the flow at the right moment is done thanks to a temperature sensor with two pairs of contacts. If the water in the tank gets colder, the circuit that feeds the pump located in the boiler circuit is activated. When the required degree of heating is reached, the contacts close and the supply of the coolant stops.

- Connection diagram via a three-way valve

It is often used when there is a large consumption of hot water. When using it two heating circuits are created. The main one is responsible for heating the room, and the additional one heats the water in the boiler tank. A three-way valve is included in the system to effectively distribute the flow of coolant between the circuits. The device is automatically triggered when the water temperature in the tank drops below the set value, and the coolant is redirected to heat it.

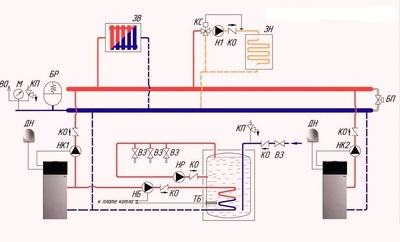

- System with hydraulic arrow

To ensure balance between the coolant flows special distributors are used.

This type of scheme is often used when it is necessary to direct hot water from the boiler in several directions.

To eliminate sudden pressure drops in various branches, stable operation of the hydraulic manifold with a hydraulic module is organized.

- Scheme using recirculation

It is used when it is necessary to ensure the maximum speed of hot water supply from the boiler. A loop highway is being organized, through which the coolant flow, regulated by the pump, circulates in a constant mode. To create such a system, it will be necessary to connect additional units, such as a check valve, an automated air bleeder, a fuse and an expansion tank.

Attention! Regardless of the scheme used, special attention must be paid to the connection of all components and units. Correct connection of the boiler to the boiler will increase productivity And get maximum power at low cost for heating water.

You can understand how correctly the connection is made if perform a device operability check and heat the water in the tank. It is necessary to measure the time during which the liquid reaches the required temperature. If the connection is made correctly, the boiler will demonstrate high performance.

Useful video

Watch a video that talks about the structure and operating principles of indirect heating boilers.

Advantages and disadvantages of an electric boiler with a boiler device

Using an electric boiler together with an indirect heating boiler it is advisable because:

- The system is automated, and the operating mode is controlled by temperature sensors.

- The pump is activated when any tap is opened, and the consumer instantly receives water at the desired temperature.

- Heat losses are minimal and occur only when water is collected.

A system that includes an electric boiler with an indirect heating boiler, In addition to the advantages, it also has disadvantages:

- High expenses. The average cost of a boiler with a tank 100 l makes up 90 thousand rublesThe cost of installing an electric boiler and the cost of energy consumed are added to this.

- Long heating period. To raise the temperature 100 l water to an acceptable level, you will have to wait several hours. At the same time, the intensity of heating in the room decreases.

- Large sizes. The boiler and the water heater are mounted in close proximity. The resulting structure cannot be called compact. A separate room is allocated for its placement.