Carefully thought out, installed once and for life: a chimney for a wall-mounted gas boiler

A wall-mounted gas boiler is usually equipped with a coaxial chimney, which is "pipe in pipe" design.

Internal the pipe serves to remove flue gases, and external to supply air to the burner in the amount necessary to maintain the combustion process. This solution is the most simple, effective and aesthetic.

Chimney device for a wall-mounted gas boiler

The operating principle of a coaxial chimney is as follows.

On the inner, smaller diameter pipe the products are removed from the combustion chamber. During the removal process, the flue gases are cooled by the cold air in the outer pipe, which reduces the fire hazard.

On the outside, larger diameter, the pipe supplies outside air to the burner. Due to the temperature of the exhaust gases, the air is supplied to the burner already heated, which increases the efficiency of the heating unit.

The main difference The chimney of a wall-mounted boiler from the smoke exhaust system of a floor-standing boiler consists of in the absence of a vertical chimney. This is due to the fact that the burners of wall-mounted boilers with a closed combustion chamber are equipped with fans. To maintain the combustion process, no additional draft is required, which in floor-standing boilers is created due to the length and diameter of the smoke tube.

An important advantage heating system based on a wall-mounted gas boiler over a similar one with a floor-standing one — is the absence of the need to construct supply and exhaust ventilation. As a result, a wall-mounted one with a closed combustion chamber can be placed, for example, in a kitchen, the parameters of which comply with current standards and regulations.

Included as standard smoke removal systems of a wall-mounted gas boiler, as a rule, includes:

- coaxial 2-segment pipe: one for vertical section from the boiler, the second one is for horizontal, for output through the wall;

- rotary 90 degree elbow, 1 piece;

- sealed gaskets, compression clamps;

- decorative overlays, as an option.

In some cases it may be necessary additional purchase of extension cords coaxial pipe, second rotary elbow at 90 or 45 degrees, tee for connecting two boilers to one chimney.

Coaxial tubes and connecting elements for them are made of steel and painted with white heat-resistant enamel. Some manufacturers make the outer element from plastic for better thermal insulation. The most common size of coaxial: outer pipe diameter 100 mm, inner pipe diameter 60 mm. Larger diameter pipes are found on condensing boilers, which have the highest efficiency and low exhaust gas temperatures. Increasing the diameter in such boilers is a measure to reduce the amount of condensate formed.

Installation of a coaxial chimney: requirements

Total length coaxial chimney should be no more than 3 meters (for condensing boilers up to 5 meters).

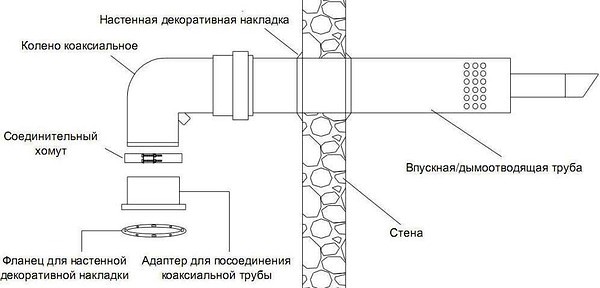

Photo 1. Assembly diagram of a coaxial chimney for gas heating. All main parts of the structure are indicated.

It is allowed along the entire length of the smoke channel no more than 2 turns (2 turning elbows).

Important! The smoke exhaust duct is routed outside through the wall. It is forbidden to take it out of the window or transom!

It is prohibited to lead the smoke exhaust duct into the entrance, onto a closed balcony or loggia., as well as on a street with buildings of architectural or historical value, children's and medical institutions.

In addition, the following must be observed: General requirements, applicable to all types of chimneys:

- Diameter should be equal to or greater than the cross-section of the outlet pipe boiler.

- He should not have any curvatures throughout its entire length, its cross-section should not decrease.

- Smoke exhaust channel must be gas-tight, waterproof, joints must be carefully isolated.

Installation

Installation of a coaxial chimney does not present any particular difficulty. In the standard case, the output is carried out through the wall, on which the boiler is mounted.

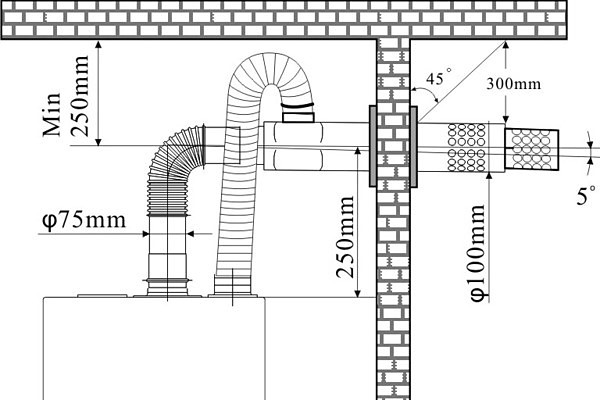

Photo 2. Installation diagram of a coaxial flue for a wall-mounted boiler. The required offsets and pipe diameters are indicated.

In this case, a pipe is connected to the device. a small piece of vertical land, then it is located 90 degree elbow. Next comes horizontal part, which is led out through a hole in the wall to the street. Length street part not less than 30 cm. The design ends with a special head.

When the smoke exhaust duct is routed offset from the boiler or through an adjacent wall the scheme is somewhat more complicated and requires purchase additional details.

Attention! To prevent condensate from entering the boiler furnace horizontal section it is necessary to have with a slope of 3 degrees towards the street.

The fitting of the coaxial chimney parts by the manufacturer is carried out carefully, additional sealing of connections is usually not required.

Diameter of the hole in the wall to remove smoke to the street, they do it a few centimeters larger than the diameter of the outer pipeOnce installation is complete, the space is sealed with mounting foam.

Some manufacturers provide delivery boilers with separate pipes for smoke removal and air supply.

This design expands the installation possibilities up to three options:

- both pipes are being output through one wall;

- the pipes are being brought out in different walls;

- air supply system is output into the wall, and the system smoke removal into an existing chimney.

Third option especially relevant for multi-apartment residential buildings.

Advice. In non-standard cases of chimney location for drawing up a diagram Contact a specialist.

Useful video

Watch a video that explains how to deal with icing on the head of a coaxial chimney.

Troubleshooting

On frosty days it is possible condensation icing at the outlet of the smoke removal system. The most difficult situation is when ice fills the space between the pipes, making it difficult to supply combustion air. This phenomenon significantly reduces the efficiency of the boiler equipment.

To some extent Insulation helps. But the most effective solution is to connect it to the exhaust pipe attachments that lengthen and narrow it.

At the expense of creating additional thrust the condensate literally flies out with the flue gases. Some modern boilers are supplied with such nozzles as standard.

The second solution is supplying the flue with a condensate collector, which is a small diameter branch at the bottom of a coaxial chimney.

Comments

During operation of the chimney, it is necessary to regularly check the draft and clean it from soot and condensate.