Eco-friendliness, reliability, safety and many other advantages of coaxial chimneys for gas boilers!

A new word in heating technology — boilers with a closed combustion chamber. Air enters the firebox of such a boiler from the street, not from the room.

This allows us to solve a number of pressing issues: supply ventilation, presence of an isolated boiler room, fire hazard.

Air supply and combustion product removal for such boilers are carried out through coaxial chimneys.

Content

What does it consist of?

The term "coaxial" is used to denote multi-layer coaxial structures., where one part is enclosed in another. Pipelines and cables can be coaxial. A coaxial chimney consists of two pipes - an exhaust pipe and an air intake. This design has a number of features, advantages and disadvantages.

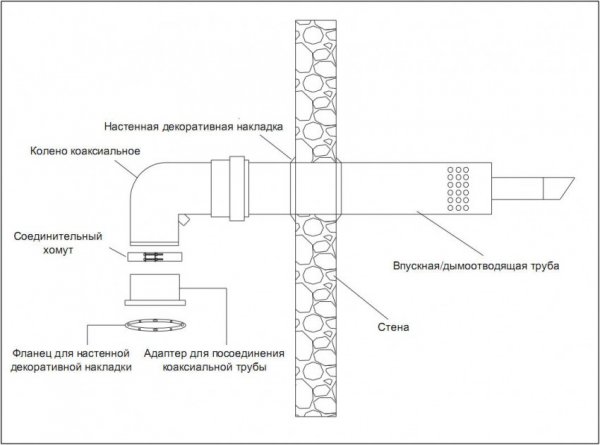

Photo 1. Diagram of the coaxial chimney for a gas boiler. The arrows indicate the components of the structure.

Standard connection set wall-mounted boiler with a closed combustion chamber:

- Metal pipe made of acid-resistant stainless steel. It serves as a means of removing burnt gases from the boiler.

- Plastic or composite pipe. It has a larger diameter and acts as an air intake from the street, as well as a casing and heat insulator.

- Distance stops for mounting pipes one to one.

- Adapter - flange connection to the boiler. Consists of two corners of the corresponding diameter with a socket of the internal metal part.

- Connecting cuffs and clamping clamp with screws. Made of heat-resistant flexible plastic.

- Wind protection. A special wind-reflecting cone protects against blowing.

- Camouflage cuffs to pass through the wall.

How it works

The task that was set when inventing a boiler with a closed combustion chamber was to completely isolate the firebox from the room. This task has many solutions, including physically placing the boiler outside. The simplest and most original way to solve it was application of the "pipe in pipe" principleHot combustion products are removed from the room to the street using a smoke exhaust fan.

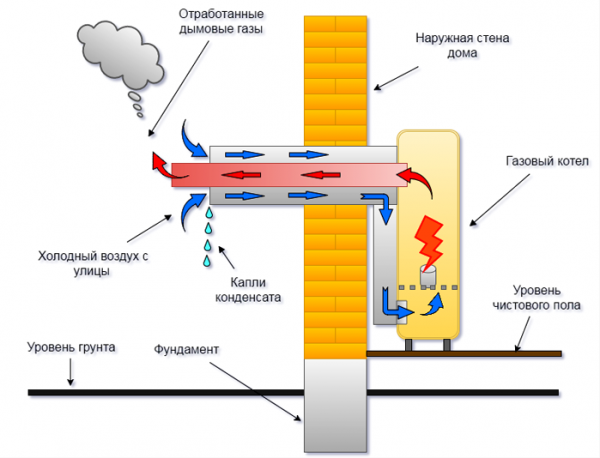

Photo 2. Operating principles and internal diagram of a coaxial chimney for a gas boiler with a closed combustion chamber.

The pipe is done made of material resistant to condensation and combustion products with high thermal conductivity. Gas temperature in non-condensing boilers - 140 °C, the pipe gets pretty hot. It's designed to prevent a fire outer part. She serves as an air intake for combustion. Passing through it, the air heats up, which significantly increases the efficiency of the boiler. Hot pipe separated from the walls by a layer of flowing air, which is the best heat insulator.

Advantages of coaxial chimneys for gas boilers

Coaxial chimneys for gas boilers have many advantages.

Ease of use

A closed combustion chamber is not connected to the room in which it is located. Boiler does not use room air, does not affect the microclimate in the house.

Saving on materials

Coaxial chimneys solve two problems: overheating or icing supply pipe.

If a separate system is used to connect a boiler with a closed combustion chamber, it will be necessary to use insulation and heat the incoming air with electricity.

The "pipe in a pipe" principle allows you to significantly reduce connection costs.

Reliability

Coaxial chimneys have a simple design, when installed correctly, ensure long-term trouble-free operation of the equipment. There is nothing to break in the designThe "mushroom" provides excellent protection against blowing, the short length of the chimney ensures low resistance.

Ease of installation

The pipe is assembled quickly and does not require much labor.Maintenance during operation is minimal.

Chimney design simple and intuitive, each manufacturer provides detailed assembly and installation instructions. No brick ventilation ducts or heavy foundations are required for installation.

Increasing boiler efficiency

Reduced hydrodynamic resistance, the ability to automatically control the flow of air and gas into the boiler, and heating of the incoming air allow achieving an ideal stoichiometric ratio of the gas-air mixture. burns almost completely, without forming soot or depositsTherefore, a coaxial chimney rarely requires cleaning.

Fire safety

Hot areas are enclosed in an air jacket of flowing air. All excess heat is transferred back to the boiler, and the outer jacket is always cold.. This reduces the risk of fire due to overheating of floors or walls. However, it is recommended to fill the free space between the wall and the outer shell with non-combustible insulation.

Eco-friendliness

With optimal combustion of natural gas harmless substances are thrown into the street: water and carbon dioxide.

Impurities in natural gas are also maximally oxidized and dissolved in steam in the form of inactive salts and oxides.

Flaws

Coaxial chimneys also have some disadvantages.

High cost

Due to increased requirements for the quality of materials And execution of butt joints. This disadvantage is offset by the fact that there is no need to build a main chimney, an isolated boiler room, or special ventilation. Such a boiler can be installed in an ordinary kitchen with standard ventilation.

Formation of condensation

Water vapor contained in the exhaust gases inevitably enters the air intake. In severe frost they can freeze, and in the off-season they can condense and drip. When freezing occurs, the air supply is reduced and the boiler may go out.

Photo 3. Coaxial chimney with frozen condensate on it. There are many devices to eliminate the problem.

To prevent this from happening, there are a number of recommendations.

The dew point (condensation of vapors) must be outside. The inner pipe can be extended to prevent heated vapors from entering the air intake.

It is possible to insulate the chimneyto reduce the air temperature.

Additional modules are available for sale, eliminating the problem of icicles and dripping condensate. They consist of an insulated nozzle: an extension and fasteners.

Disadvantages of a coaxial chimney are easily and inexpensively solved.

Installation requirements

Installation types:

- Horizontal. Mounted when passing through the wall.

- Vertical. Mounted when passing through the roof.

- General. It is used in apartment buildings with modular heating; several boilers are connected to one riser.

Most often, horizontal installation is carried out along the shortest route to the street. If necessary bends are added when using turns at 45 and 90°. It is worth remembering that as the complexity increases, the hydrodynamic resistance of the chimney increases. Each turn 90° equal in resistance 1 meter pipes, 45° - 0.5 meters.

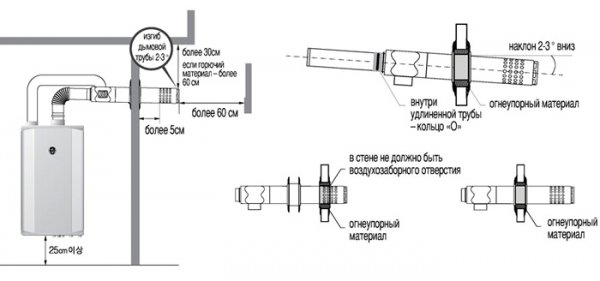

Photo 4. Diagram of horizontal installation of a coaxial chimney. The structure should be at a slight angle.

When passing through the roof, additional equipment will be required. node of passage through floors and roof, and also deflector cap and condensate collector.

The boiler specifications necessarily indicate the necessary requirements for the chimney. They must be observed, since otherwise the heating efficiency may deteriorate. As a rule, the length does not exceed 3 meters. When designing, it is necessary to remember about the increased resistance of corners and bends.

When placing horizontally, it is imperative to observe slope towards the street. This is necessary so that the resulting condensate drains and does not get into the boiler. Recommended parameter: 1 cm per meter of chimney.

From the boiler to the wall passage It is better to ensure a distance of 50 cm. The incoming air will be warmed up and there will be no icing of the pipe inside the room.

Inside the building it is important distance to ceiling: 35 cm. Outside, distance is important from the ground - not less than 2.2 meters.

There should be a distance from the end of the chimney to adjacent buildings not less than 60 cm, ideally - not less than 1.5 meters.

The exhaust must dissipate freely into the atmosphere.

Nearby windows and vents must be kept at a distance 60 cm from the release of combustion products.

Length of the part protruding onto the street The pipes are minimum 30 cm.

Attention! Connections inside walls are not allowed! There must be a solid section running through the wall.

Insulation is not required in most cases. When the pipe passes through the wall the hole is filled with non-combustible insulation.

Installing a chimney with your own hands

We prepare the necessary tools: hammer drill, level, tape measure, pencil, Phillips screwdriver.

Before installing the boiler, be sure to we lay out the route of the chimneyThe pipe should not rest against wiring or communications.

Important! It is mandatory when designing slope towards the street at least 1 cm per meter!

We assemble the chimney according to the manufacturer's instructions. To do this, we attach the inner part of the pipe to the adapter, then put the outer part on through a flexible coupling. We clamp the connection with a plastic clamp.

We make a hole in the wall with a hammer drill the hole is 5-10 mm wider than the pipe chimney.

We put on the decorative coupling, thread the chimney through the hole in the wall. We put it on the boiler connector, fix the adapter with screws to the boiler. It is necessary We check if the chimney fits tightly.

We fill the gap between the pipe and the wall with non-combustible insulation: basalt wool. Mounting foam should not be used - this may cause difficulties during dismantling or repair.

We press decorative extensions against the wall. They prevent steam from passing into the insulation and eliminate the cold bridge. The extensions can be glued to the wall with silicone sealant.

Useful video

Watch the video, which talks about the options for installing a coaxial chimney.

How to determine if the flue is working properly

With coaxial designs, problems arise extremely rarely, and They are due to improper installation or design.

Signs of malfunction will be too frequent switching on of the boiler, flame dying out — the automation will go into emergency mode.

Formation of condensation and wind blowing will also require intervention in the operation of the boiler.

A well functioning chimney does not make noise, in cold weather visible steam emission is possible.

Indoors Icing of external walls is not allowed even in cold weather.

If there is a suspicion of incorrect operation, it is worth identifying the cause: high hydrodynamic resistance, non-compliance with boiler technical requirements, lack of slope, wind blowing. Each of the reasons requires its own approach to correction, from adding additional units and elbows to a complete replacement of the chimney.