Safe installation in accordance with SNIP: types of correct chimneys for gas boilers

A gas boiler is considered one of the most efficient sources of heating in the home. Gas is cheap, and systems that generate heat with its help are sold in most stores.

Since combustion products are formed during the operation of the boiler, channel needed, by which they will be removed from the unit.

The role of such a channel is played by the chimney, design and layout whom affect work efficiency gas boiler. There are different types of chimneys and each of them has its own characteristics.

Features of a brick chimney for a gas boiler

A brick chimney for a gas boiler is, rather, a forced necessity rather than a desirable option.

If you make a regular brick chimney, then if it is not used correctly, it can will soon collapse.

This is due to the low temperature of smoke from a gas boiler (120 °C) does not heat the walls of the channel in cold weather, on them condensation is formed and the material is destroyed.

In winter, frozen condensate reduces draft, which leads to equipment malfunction. Therefore, if you are making a new chimney, it is better to choose other materials and technologies. But if you have to restore or use an existing brick channel, you need to finish it.

Operating principle

The operating principle of the brick version repeats the general operating principle of chimneys. Due to the difference in air temperature inside and outside the pipe, draft occurs. Moreover, the draft is stronger the higher the pipe, so it is important to install it at the correct height.

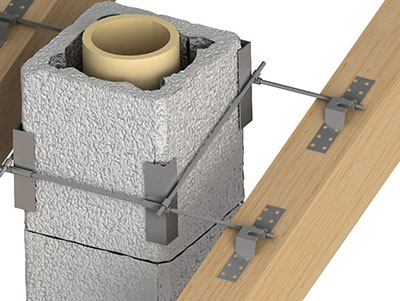

The design feature of the brick version, especially if it is being built anew, is the need for a foundation. When it comes to a wall-mounted external pipe, its base must be reinforced. metal rods. Another feature of the brick version is the need for insulation or lining.

Photo 1. Several brick chimneys installed on the roof are used in cases where it is not possible to install others.

Even if the brick chimney is made in accordance with the requirements - from fireclay bricks, with a sealed seam of thickness 1 cm, with a deflector to increase draft - the efficiency of the channel will be lower without insulation. When the pipe is located outside, this must be done along its entire size, which, in turn, is determined combustion chamber volume gas boiler.

The best material for insulating a pipe is non-flammable basalt wool, which is glued, then a reinforcing mesh is stretched, and a finishing coat is applied on top (for example, with a metal profile).

Important! Even if a brick chimney goes through an unheated attic, it too must be insulated.

If the chimney is laid in a brick wall, it is necessary to carry out its lining. To do this, a sandwich pipe or single wall stainless steel pipe, wrapped in insulation.

Photo 2. A stainless steel pipe is inserted into a brick chimney, and sealed foam is used for insulation.

Unlike a stainless steel pipe, which can work properly more than 20 years, a well-made brick chimney will last without repair about 6 years. Despite this disadvantage, the equipment of the shaft for a gas boiler will require less expenses if the house already has a brick channel. Plus, if you have to change the boiler, the brick chimney is suitable for units with other types of fuel.

The right stainless steel chimney

The chimney channel made of stainless steel pipe is made significantly faster than brickAmong its advantages:

- availability of material;

- long service life;

- ease of installation.

Photo 3. Stainless steel chimney indoors, easy to install, has a long service life.

Operating principle and gas temperature

The operating principle is similar to the brick version. Thanks to natural draft combustion products are removed from the gas boiler to the street through a stainless steel pipe. It is best to bring the pipe outside through an external wall. The necessary draft in a stainless steel pipe can be achieved by raising the chimney to a height at least 6 meters and ensuring the tightness of the joints.

Exhaust gas temperature reaching 120 °C, leaves a risk of condensation, the channel needs to be insulated. To do this, the stainless steel is lined with basalt wool, and then covered with roofing sheet metalThe result is a sandwich that best promotes normal system operation.

Condensation appears on a metal surface faster than on any other surface.

Therefore, the design features of a stainless steel pipe include the one located at the bottom of the pipe that is brought out condensate collectorAbove it there is a section with an inspection area - a place for cleaning the shaft.

Above is a straight section of a stainless steel sandwich flue pipe, which ends with a cone-shaped cap. If it is necessary to change the trajectory of the pipe due to architectural nuances of the building, It is necessary to remember about SNiP. The rules state that:

- length of horizontal segment the chimney in front of the vertical part should not exceed in total 3 meters;

- the shaft may deviate, to go around the roof overhang, 1 m at an angle of 30° in relation to the shaft axis;

- the number of turns in the chimney should not exceed three, with the exception of the elbows that go around the roof overhang;

- These and other requirements are usually presented by the inspector when obtaining permission to connect the boiler to the gas pipeline.

Attention! When connecting a closed-type gas boiler, a coaxial chimney is installed. Its operating principle differs from a stainless steel chimney, and The installation has a special scheme.

A stainless steel pipe is considered one of the most cost-effective options for a chimney duct for open-type gas boilers.

Its main one can call it a plus probability of assembly and installation independently without significant costs for materials and tools.

Due to its strength and tightness, as well as ease of insulation, the efficiency of a steel pipe is higher.

Among the disadvantages stainless steel chimneys - appearance, which may stand out from the exterior of the building. In addition, if gas is replaced with another type of fuel, the pipe will most likely have to be changed along with the boiler.

Ceramic tube device

Ceramic chimney is a profitable, but expensive solution for a gas boiler. Moreover, if a brick channel and a stainless steel pipe can be made by yourself, then the ceramic version must be purchased in a factory configuration and installed in strict accordance with the instructions.

The characteristics of the draft in a ceramic chimney depend on the same conditions as in other pipes: the boiler must be provided with an air supply, and the height of the pipe must be more than 6 m. The temperature of gases in the ceramic shaft from the gas boiler, as well as in other pipes, reaches 120 °C. In this case, you can choose an option designed for low and high temperatures. In the second case, it will be possible to connect boilers with different types of fuel to the ceramics.

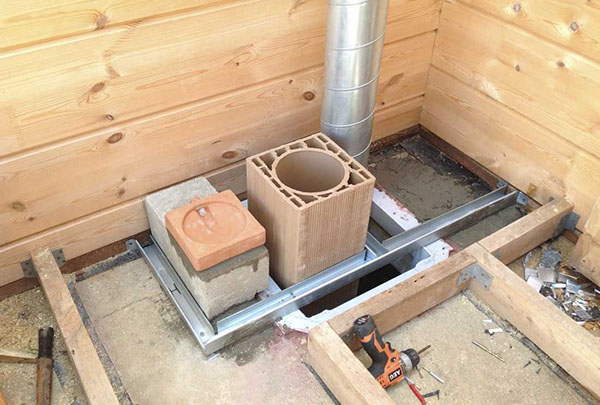

Photo 4. The process of installing a ceramic chimney, produces little condensate, suitable for different types of boilers.

How does it work?

The principle of operation of the ceramic shaft is in the removal of exhaust gases from the boiler under the action of draft. Due to the material of manufacture - ceramics, non-combustible basalt insulation and ceramic chimney brick, it is possible to avoid large amounts of condensate.

At the same time, the service life of a ceramic device exceeds all other options and can reach 50 years oldBut such indicators are possible if the ceramic pipe is installed correctly.

The thing is that, just like a brick one, it requires a foundation. In addition, experts recommend placing a ceramic shaft exclusively vertically.

The only horizontal section that is allowed on it is part of the tee for running pipes through the wall and connecting a gas boiler.

Ceramic pipe requires regular maintenance. Therefore, above the condensate collector and ventilation grille installed at the very bottom, there is an inspection (cleaning hole). Above the tee there is a straight section, which is completed at the very top by a cone or deflector.

It is worth noting that a ceramic pipe does not pose such a danger when in contact with a wooden wall of a house as a metal one, because it heats up less. But the distance between it and the pipe at the place of its wiring still needs to be left and laid with basalt wool for insulation. In this, as in many other cases, it is necessary take into account SNiP.

The advantages of a ceramic chimney are its safety, long service life, a ready-to-install kit that is assembled like a construction set. The disadvantages are the high cost, significant weight, requiring a separate foundation, and the need for installation strictly in a vertical position.

How to check the draft?

In order for the draft in the chimney to facilitate the normal operation of the gas boiler, it is necessary to install a pipe to the correct height. If it is installed on the outside of the building, its height should be not less than 6 m.

If the chimney passes through the house's floors, its height on the roof is determined by the distance to the ridge. Thus, with a gap from 1 to 1.5 m. up to the ridge the height of the pipe above its level should be from 50 cm.

When moving away from the ridge by 1.5–3 m its height can coincide with the height of the pipe. On a flat roof, the height of the chimney is set at the level 100 cmIt is worth remembering that the draft is affected not only by the height of the pipe, but also by its thermal insulation.

You can check the draft in different ways. For example, look flame color in gas boilerIf it periodically changes to red, this indicates a lack of oxygen for combustion.

You can check it too a sheet of thin paper, brought to the chimney opening. If it is sucked into the channel, then there is a draft. Only a clean chimney provides good draft. Its patency can be checked with a metal ball attached to a rope. It must be lowered from the top of the shaft to the bottom. If it goes all the way, the chimney channel is clean and the draft will be excellent.

Reference! The most convenient method of testing should be chosen based on whether the channel design allows it. In this case, testing the draft with a sheet of paper is suitable. for all types of chimneys.

Finally, to obtain more accurate data on the thrust, you can use a special device - anemometer.

Useful video

After watching the video, you can familiarize yourself with several diagrams for the correct installation of chimneys.

Safety

The chimney not only provides draft for the combustion process in the gas boiler, but also creates safe conditions for being in the room, removing harmful gases from it. Their presence is a direct indicator of improper operation of the chimney.

If you smell gas or combustion products in the room, it means that the burner has gone out or smoke has started to enter the building.

In both cases it is necessary stop the gas boiler immediately, ventilate the room and repair the chimney.

To detect a malfunction, it is necessary to check all elements of the chimney duct step by step for their compliance with existing operating standards.

If you can't solve the problem yourself, you need to call an experienced repairman. He will be able to better understand the problem and fix it well chimney for gas boiler.