Will not let you suffocate with combustion products! Chimney for a gas boiler in a private house

The chimney serves to remove combustion products from the heating appliance to the street..

It is used together with gas boilers, water heaters and other equipment in private houses of permanent and temporary residence.

Device

The inner surface of the gas outlet channel can be round, oval or square.

Regardless of the material it is made from, it must be resistant to high temperatures, moisture, and aggressive environments.

According to the material they are made from, chimneys are divided into:

- brick;

- coaxial;

- ceramic;

- made of stainless steel;

- made of galvanized steel;

- asbestos-cement.

Attention! Asbestos cement pipes use forbidden.

Asbestos cement is harmful to humans, and there is a risk of fire and explosion during work. Galvanized steel is subject to corrosion, its service life does not exceed 5 years.

Stainless steel is resistant to mechanical, temperature, chemical influences. Smooth walls provide good draft. The modular design allows you to install the chimney at any angle, it is easy to clean and repair. Service life 15 years old. Areas located outside heated rooms must be insulated (or sandwich pipes must be used).

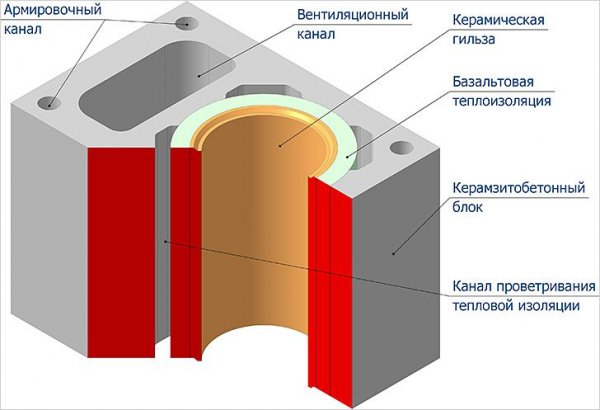

A ceramic chimney consists of an insulated ceramic pipe placed in a protective block of brick or concrete. The structure is resistant to temperature fluctuations, waterproof, and serves up to 30 years. Massive blocks require a foundation, and the channel itself can only be vertical.

Photo 1. Scheme of the ceramic chimney for a gas boiler. The arrows indicate the components of the structure.

Coaxial chimney for a gas boiler in a private house

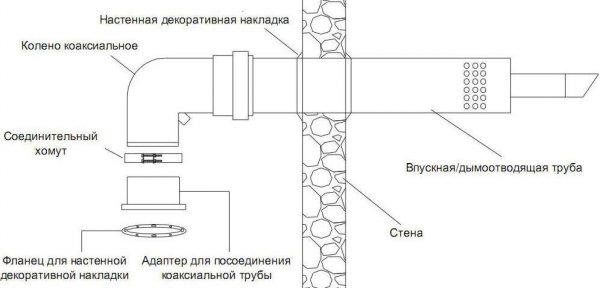

Consists of two pipes, separated by spacers, and performing two functions simultaneously: combustion products are discharged through the internal channel, and the space between the pipes serves to supply air to the heating device. The elements are separated by spacers along their entire length.

Reference. Also used with gas water heaters.

The design allows for the installation of coaxial chimneys on equipment with a closed combustion chamber. With floor-standing and wall-mounted gas boilers, a system is used consisting of an external steel pipe with a diameter of 10 cm and an inner tube made of aluminum alloy with a diameter of 6 cm.

Photo 2. Part of the coaxial flue of a gas boiler, going outside. Such a flue is located horizontally.

When moving through the pipes, the exhaust gases cool down, and the incoming cold air warms up. Heat exchange of gases does not allow the wall to heat up too much, increases the efficiency of the boiler, and ensures maximum fuel combustion. Combustion products do not enter the room, and the supply of air from outside does not require the installation of additional ventilation.

Brick chimney: its dimensions

It is assembled from solid ceramic bricks, laid on mortar. A massive structure requires a separate foundation. It is allowed to place it in the outer wall of the building, which requires additional insulation.

Minimum channel size - 14x14 cm, internal section square or rectangular. The walls must be as smooth as possible, otherwise the service life of the chimney will be sharply reduced.

Uneven surfaces contribute to the formation of condensation, and the material itself does not tolerate exposure to aggressive environments.

When converting old buildings to gas heating They produce lining of existing brick channels: An insulated pipe made of metal or ceramic is installed inside, which serves to remove gases, and the former chimney acts as a protective box.

Requirements for chimneys

The main functional requirement is the complete removal of combustion products. Safety requirements:

- complete gas impermeability of the material chimney and tightness of joints;

- absence of cracks and other mechanical damage, allowing combustion products to enter the room;

- prohibited to place in living rooms, on closed balconies and loggias;

- all rooms through which the gas exhaust system passes, provide ventilation;

- passage through fireproof walls and ceilings insulated with polyurethane foam, through flammable ― refractory material;

- minimum distance from the chimney to the wall with a non-combustible surface ― 5 cm, flammable - 25 cm.

Attention! Failure to comply with the requirements for the tightness of the gas exhaust system may cause poisoning by combustion products.

Design requirements:

- absence of ledges and narrowings;

- deviation from vertical no more than 30°;

- no more than three turns and branches;

- branch length no more than 1 meter;

- angle of the rotary knee not less than 15°;

- knee radius not less than the pipe diameter;

- horizontal sections are located at a slope of 3-5% towards the boiler branch pipe;

- the pipe does not bear any additional load, deflections are excluded;

- at the place where the walls, ceilings and roofs pass, they are placed solid chimney elements;

- prefabricated elements are inserted into each other to a depth not less than half the diameter of the pipe;

- availability tees, revisions, condensate collector;

- insulation of areas located outside heated premises;

- they connect to one chimney no more than two heating devices;

- if the heating devices are located at different levels, the inputs are placed at a distance at least 70 cm from each other;

- It is permissible to place devices on the same level when installing divider inserts at the inputs, while the distance between the inputs not less than 100 cm;

- the cross-sectional area of the channel is selected not less than the sum of the cross-sectional areas pipes of all simultaneously operating devices.

Installation of coaxial chimneys requires compliance with additional requirements:

- length of coaxial chimney does not exceed 4 meters;

- when wiring through walls and ceilings, they are usedI have special adapters and extension cords;

- protection against ingress of foreign objects and precipitation (provided with a terminal head);

- minimum distance from the outlet to any opening element of the facade ― 40 cm;

- to any air intake opening ― 60 cm.

Special requirements for the construction of brick chimneys:

- height of foundation for chimney not less than 30 cm, the dimensions in plan exceed the external dimensions of the channel by 15 cm;

- It is necessary to bandage vertical seams during laying;

- constructed between heated rooms;

- minimum permissible cross-section of the gas exhaust duct ― 14x14 cm;

- at altitude less than 5 m - 14x20 cm.

Do-it-yourself construction: choosing a project scheme

The project is determined depending on the building and the heating device. Depending on the installation location, there are internal and external chimneys.

The former are usually provided for at the design stage, the latter - when converting existing buildings to gas heating.

There are boilers with open and closed combustion chamberThe first ones feed the combustion process with air from the room, the second ones – from the street.

Important! Provides maximum thrust circular cross-section, minimum ― square.

Suitable for open type boilers brick, ceramic, steel chimneys. The pipe is placed either strictly vertically, or first horizontally to the outer wall, and then at a right angle upwards (remote version). The first option is more difficult to install, the second requires insulation of the outer sections of the pipe.

The chimney is located at a distance not less than 1.5 m from the edge of the parapet. On flat roofs, the height of the chimney is 1 m, on combined ones - 2 mOn pitched roofs, the height of the chimney depends on its location relative to the ridge:

- The pipe will stand 1.5 m or less - the height must exceed the ridge by 0.5 m.

- 1.5-3 m - the top point is at the same level as the ridge.

- 3 m and more - the top point of the ridge is determined by the inclined line drawn downwardsz by 10° from the horizontal at the ridge level.

Reference. The easiest to install horizontal coaxial chimneys.

A coaxial chimney is used for boilers with a closed chamber. The pipe is horizontally led to the outer wall, the distance from its outer surface to the ceiling not less than 20 cm. The terminal protrudes from the wall. by 30 centimeters or more. If the distance to the outer wall more than 4 meters, then the pipe is brought out vertically upward.

Photo 3. Installation diagram of a coaxial chimney for a gas boiler. The product is installed horizontally and passes through the wall of the building.

Materials and tools

The materials are not suitable for constructing a chimney with low density, porous, hygroscopic, unstable to mechanical, temperature, chemical influences. Materials with high thermal inertia reduce the efficiency of the boiler during the heating of the flue system.

The installation kit includes:

- flue gas duct;

- pipes (including telescopic);

- knees And connecting clamps;

- through pipe;

- head (terminal or cone-shaped);

- tee with revision;

- condensate collector;

- seals, membranes;

- fasteners;

- decorative overlays.

Photo 4. Part of a steel pipe used for installing a chimney. The product consists of two layers with insulation between them.

For installation you will need: hammer drill, drill, mixer. The fasteners are mounted to the wall using dowels, and the holes are drilled using a hammer drill. The solution is mixed using a mixer or a drill with a special whisk attachment.

The brick chimney is laid on a mortar, the composition of which depends on the section being completed. The outer section is laid on a cement-sand mortar with plasticizers. The mortar for the inner masonry is diluted from refractory clay and chamotte in a 1:1 ratio.

Assembly instructions and common mistakes

The assembly process consists of 8 steps:

- Selection of internal section based on the boiler capacity and the design height of the chimney.

- Marking future holes And places for installing fasteners, creating openings.

- Connecting the chimney to the boiler pipe, installing a tee with an inspection hole.

- Mounting brackets and gradual pipe extension.

- Strengthening joints with clamps.

- Brackets and clamps are installed every 4 and 2 meters respectively.

- Insulation of external areas with mineral wool sheets (if necessary).

- Checking the tightness of joints.

Inadequate insulation and sealing of joints ― the main mistakes in independent construction. Thermal insulation is neglected, the technology of laying mats is violated, damp, out of order, substandard materials are used. Such "insulation" is completely removed and replaced.

Useful video

Watch a video that talks about the design of chimneys for gas boilers.

Monitoring the condition of the flue gas exhaust

Criteria for correct operation ― draft and absence of smoke in the roomA full assessment of the condition is carried out by specialists using an anemometer.

In domestic conditions, a primary inspection of the smoke in the room is carried out, and the draft at the viewing window is assessed using a thin sheet of paper.

Causes of traction problems:

- Chimney contamination. In this case, the channel is cleaned using a device consisting of a brush, a sinker and a rope.

- Breach of tightness. Cracks are sealed with mastic. In advanced cases, partial dismantling of the damaged area is performed.

- Violation of thermal insulation of external areas.

- Weather.