In this case, an extremely competent approach is needed! Connecting gas boilers in private houses

When buying a boiler, there is often a problem with its installation. There are many craftsmen on the market who install solid fuel boilers.

There are obviously companies in your city that will help for a reasonable fee, too. And the largest ones organize the departure of their employees to your home even in other cities. Therefore, it is not difficult to order a specialist.

You can find out about existing ones from newspapers or from the Internet. For example, in Moscow, boiler installation is carried out by BaltGazService, Terem, Teplomatika. These companies will deliver to your home and install it, as well as connect it to the network. Or you can buy the boiler yourself and simply call a specialist for installation.

You can, of course, try to install it yourself. But it is important to take into account that according to the rules of the gas service Only specialists with certain certificates can make the connection. That is, people who are allowed to do this by law. Therefore, even if you install the device yourself, it can only be started by professionals and in the presence of a gas service employee, with the presentation of a license to work with gas equipment.

How to connect a gas boiler in a private house: rules, diagram, cost

A set of equipment for installation of the boiler unit:

- expansion tank;

- circulation pump;

- with a two-pipe system you will also need collectors, or combs;

- safety valve relief of excess pressure;

- auto air bleed valve;

- pipes.

Attention! You can buy a boiler and install it yourself, but can't be launched.

When connecting solid fuel boilers, it is important to take into account that they have There is no function to regulate heat supply. That is, the fuel burns in them continuously. If suddenly the electricity goes out at the dacha, then the pump responsible for the forced movement of energy in the heating system will stop working along with it. But the device is designed in such a way that it will continue to heat up and eventually the entire system will fail.

To prevent this from happening, prepare your equipment in advance and tools for emergency cold water supply, connecting the pump to batteries or a generator; and also prepare a gravity circuit and an additional emergency circuit.

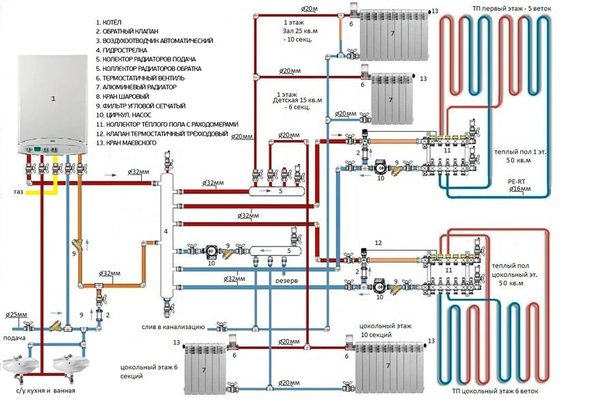

Photo 1. Diagram of connecting a gas boiler to heating radiators and underfloor heating. The numbers indicate the parts of the system.

When purchasing new equipment, some of the necessary items will be sold as a set. For example, expansion tank.

Reference. The cost of connecting a gas boiler by professionals will be from 10 to 20 thousand depending on the company and region.

Possible adjustments

It happens that the water speeds are lower than recommended. In this case the piping scheme needs to be changed. It is difficult and dangerous to do it yourself, so it is better to call a specialist. You can change the piping scheme without emergency situations. For example, sometimes boilers are supplemented heat accumulator. Or install several pumps instead of one.

Then one will be on the section from the boiler to the accumulator, and the other on the line where the coolant is already draining. Due to this, less condensate accumulates in the boiler.

It is better to find out about possible adjustments from gas service employees., since each individual case has its own gas system and nuances.

Materials and tools for connection

Self-installation is a labor-intensive and difficult task. This will require certain materials and tools. You will need to prepare the place where you will place the boiler.

Important! The place where the device will be located can be a separate room (boiler room), or just some part of the house. Optimally: room not less than 18 m3. It is important that there is a window with a vent nearby. All coverings around the boiler must be non-flammable.

To install a gas boiler you will need the following tools:

- perforator with a set of drills of different diameters;

- ball valves;

- set of specialized keys for gas equipment;

- spanners different diameters;

- voltage stabilizer;

- adjustable wrench;

- dowels;

- building level;

- mesh corner filter on the water;

- three-wire cable with a fork;

- brackets;

- gas tap;

- gas meter;

- grounded socket;

- distilled water.

Step-by-step instructions for installing a boiler to an electrical and gas network

- First you need to do something hole for the coaxial pipe to exit to the outside.

- The brackets are fixed to the wall parallel to the floor. The equipment will be hung on them. Check for any tilt using a level.

- Connection to water supply.

- Next, a mesh corner filter is mounted with ball valves on both sides of the water pipe.

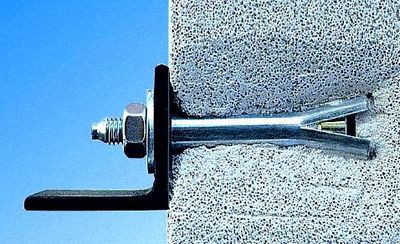

- Installation of ball valves on all gas boiler pipes.

Photo 2. Connecting ball valves to a gas boiler. The devices are mounted on the heating circuit and DHW.

- All shut-off valves and automation are installedThe device is connected to a three-wire cable with a plug at the other end.

- The attachments are mounted. At this stage, it is important to check how the boiler works. For example, whether water is leaking or gas is not being released. To do this, it is recommended to gradually fill the system with water, air is released in the bleeders. Use a soap solution to check if the pipes are intact and if there are any gas leaks.

Attention! The first launch may be made only professional, a representative of any company that will subsequently service the boiler.

Useful video

Watch the video, which tells about the rules of installation and connection of a gas boiler.

Signs of malfunction

After installing the boiler, pay attention to how it works. There are several points, noticing which you need to immediately contact professionals. Here are the signs:

- Very high fuel consumption. In this case, the device, like an insatiable monster, devours wood or coal at a furious speed. Two or three hours after a full load, it is empty again and needs refueling.

- Unable to regulate temperature water supply for heating.

- The third point is also easy to notice. If you have filled the tank to the full, but the temperature does not rise above 60 °C.

- Explosions are heard in the chimney.

- You can see it on the chimney discharge of resin or tar.

- Fast boiling.

- The batteries are cold, and the boiler shows a high temperature.

If you notice one of the seven signs, do not try to figure out the problem yourself. It's better to contact specialists immediately., fortunately, there are a lot of them on the market.

Once a year A gas worker will come to your home to check the operation of the boiler. If there are any problems, you should contact the company that services the device to fix them.