Every detail must be taken into account! Installation of a gas boiler in a private house

Gas heating systems are efficient, but require strict adherence to installation standards, since if the gas comes into contact with an open flame source (an ordinary spark), it will ignite.

Therefore, when installing a gas boiler, you need to be extremely careful, and it is best to resort to the help of a specialist.

Content

Installation of a single-circuit, double-circuit gas boiler in a private house

Installation of a gas boiler in a private house is carried out according to special rules.

Who installs one or two heating devices?

Independent installation of the gas pipeline and boiler is not possible, therefore the participation of engineers is required.

The home owner enters into a contract with the city or regional gas utility to install a gas pipeline and deliver natural gas to the home.

After which he pays for the work: project development, installation of pipes, materials and supervision of specialists - everything should be done only by employees of the installation team of the local gas service.

When the work is completed, the inspector-engineer checks the area and provides permission for gas supply, if everything is in order (he is personally responsible for this). The installation of the device itself is also carried out by Gorgaz employees, since the gas pipeline and the boiler are a single system, the tightness of which must be controlled by qualified people. Of course, the homeowner's premises must meet the technical requirements for the installation of such a heating system.

Requirements for the premises, installation of a floor or wall-mounted boiler in a wooden house

Installation of gas heating in a wooden house is possible, moreover: this is one of the most popular solutions for heating private homes. But the owner of the premises will have to spend a lot of time in technical authorities to obtain the necessary documents and permits, as well as arrange for an inspection by a gas service employee in his house for consultation and verification of the possibility of installing a boiler.

Photo 1. Boiler room in a private wooden house. There is a window in the room to provide access to sunlight.

The basic requirements for installing gas heating in a private wooden house are as follows:

- Boiler and the necessary equipment (generator, uninterruptible power supply, etc.) will be located in a separate room: it should not be a basement, bathroom or living space. In some cases, with the inspector's permission, you can install a boiler in the basement, but this is clarified on an individual basis. It is best to make an extension to the house - a boiler room, so that the inspectors have fewer questions and comments.

- Wooden walls in the boiler room must be treated with a heat-protective compound, and the use of flammable materials, false ceilings and false floors is prohibited. If this is an extension, it is better to make it from concrete blocks or bricks, although this is not necessary, but the inspectors will certainly appreciate the responsibility of the homeowner. In a wooden room, first of all, a protective panel is fixed to the wall for the boiler (both suspended and floor-standing) from a layer of basalt insulation and a steel sheet.

- The height of the boiler room ceilings is from 2.5 m, the minimum amount of space inside is 8 cubes. Door width - from 0.8 m without tight contact with the floor for additional ventilation.

- Mandatory access to fresh air: at least one opening window and openings of the required width (calculated individually) for air circulation.

- Correct installation of a chimney: with fire breaks, without decorative elements and, preferably, with a deflector; horizontal sections of the flue gas duct should not be longer than three meters, and there may be no more than two couplings along its entire length to create a bend.

Important! In a wooden house, the ceiling will most likely also be made of wood, a flammable material, so when installing a chimney, you need to use safe ones. heat-protective basalt pads.

What materials will be needed for the work?

The main device in this case is a gas boiler. As a rule, it comes with the necessary fasteners and brackets, so for installation you will only need a tool and screws, bolts.

Already To ensure the boiler operates, you will need a few more materials:

- Basalt insulation And steel sheets for thermal insulation.

- Pipes and chimney parts, the number of which is calculated based on the design length of the latter (the engineers who drew up the project will name the exact length and help calculate the required amount of material).

- Details for electrical and hydraulic piping of the boiler: pipes, wires, a boiler and an electric generator with an uninterruptible power supply, if the homeowner deems their installation necessary.

- Tapes and pastes for sealing joints of gas and smoke exhaust pipes.

Necessary tool

To perform the work, you will not need to use expensive and technically complex equipment, since the main part of the installation is carried out by gas service specialists with their own equipment. Basic list of tools:

- Set of spanners for working with pipes and fasteners.

- Specialized a set of tools for installing gas equipment.

- Mounts, brackets, racks.

- Dowels, hinges, self-tapping screws, screws.

- Adjustable wrench And gas tap.

Photo 2. Gas valve installed on the pipeline. The product can be used to shut off the gas supply.

- Perforator, if the work will be carried out on concrete or brick floors.

- Building level to create the required slope of the flue.

- Ball valves.

- Gas meter And voltage stabilizer.

- Tools for electrical work.

Preparatory work

Preparatory work includes not only running around to different authorities and collecting the necessary documentation, but also performing a number of actions before installing the boiler itself.

Initially it is necessary to bring the premises (the future boiler room) into proper condition: install grounding if there is none, install doors, an exhaust system, vents and protect the walls from fire by insulating them with resin or basalt insulation.

It is important that there is constant air circulation in the boiler room, for which purpose additional ventilation holes are made in this room.

When the stand or mount for the gas boiler is ready and the protective screen is installed on the wall, then it is possible to install a smoke exhaust, after which you can install a boiler and an electric generator in case of power outages.

Attention! You cannot proceed directly to the installation of a gas boiler until the completion of preparatory work.

How to install a chimney with your own hands: diagram

There are several technological solutions for installing a chimney, and some rather outdated types are still in demand. structures with a brick shaft through the entire house.

Of course, it is not necessary to make a shaft for the pipes, especially if the pipe is located inside the building itself, and not outside, but still, aesthetically, a brick shaft is much better than a bare pipe, and this is probably the reason for the popularity of an outdated and expensive solution. Installation of a chimney allows harmful substances to be removed, obtained as a result of gas combustion in the boiler chamber. The air for combustion, in most cases, is taken from the room itself.

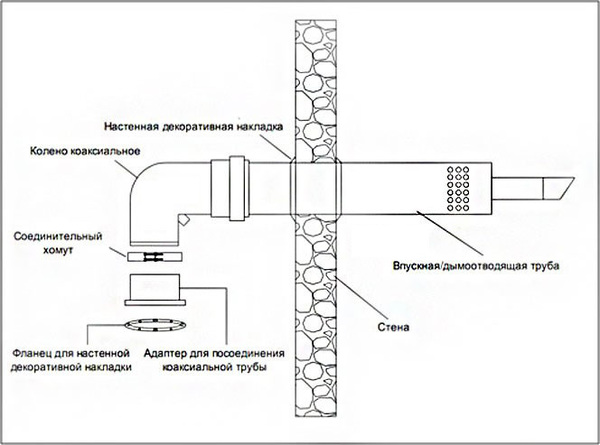

The modern and optimal design for smoke removal is coaxial (pipe in pipe), since it allows to do without the installation of a large number of pipe sections, to refuse the construction of a shaft and not to take air from the room to maintain the fire inside the boiler, since air will be taken from outside the building through the external pipe, and smoke will be removed through the internal one.

Photo 3. Diagram of installation of coaxial flue for gas boiler. Arrows indicate parts of the structure.

To implement a standard chimney, you will need to stock up on both patience and materials, since you will have to hard work with many regulations. That is why it is better to entrust the installation of a classic chimney to a professional, and if you carry out the removal of smoke from the boiler yourself, then use a coaxial design.

Installation of gas heating system

By design, gas boilers are divided into single-circuit and double-circuit: the former are used only for heating the house, the latter heat the room and supply the home with hot water. The installation of the systems does not have any serious differences: only the number of pipes (circuits) of connection differs. The differences begin at the stage of connecting radiators and batteries. The main stages of installation after the work on preparing the premises:

- Attach a bracket or a riser to the load-bearing wall (if the device is floor-standing).

- Install the boiler, checking the correct position using a building level or plumb line.

- Connect the unit to the hydraulic and electrical connections, which are connected to the boiler, expansion tank and electric generator.

- Install on hydraulic pipes filter, and on the electrical wiring - uninterruptible power supply.

- The system is checked by the controller, and then the engineer installs the gas piping.

Useful video

Watch the video, which explains the principles of installing the Aton gas boiler.

Labor that pays off

Working with gas equipment is difficult, but the boiler is a universal option for heating a home. In addition, using a gas boiler is economical, which is why it pays for itself in the coming years. But, of course, it is important to comply with safety requirements and agree to the help of engineers and installers where you cannot cope on your own.