Standards and requirements for ventilation of gas boilers: how to ensure the safety of your home?

The main task of ventilation is ensuring air circulation in a closed space — the influx of oxygen and the removal of combustion products from it.

Substances formed during the combustion of gas, if they accumulate and are inhaled by people, can lead to deterioration of health and even cause irreparable harm to health, even to the point of death.

Additionally, without proper ventilation, even a small leak of natural gas, which is the fuel for a gas boiler, can accumulate and form a flammable and explosive mixture. Lack of fresh air supply to the working boiler significantly reduces efficiency — heat output falls, and gas consumption increases.

Types of room ventilation for a gas boiler

By the method of air movement The following systems are distinguished:

Natural movement

In this case, air moves due to the difference in pressure and temperature inside and outside through ventilation openings, windows, and doors.

Such a system cannot be controlled and may not work effectively, for example, in summer, when the temperature difference between inside and outside the room is insignificant.

To avoid problems when choosing such a ventilation system, you need to equip supply and exhaust ducts, based on natural draft.

Ventilation pipes are installed in pre-prepared holes in the wall, equipped with a mesh to protect against debris and a check valve to separate the outgoing and incoming air flows.

This system is also used as an additional one, to improve the overall effect from ventilation.

Artificial or forced

In this case, use fans. Air circulation is regulated mechanically. Depending on the diameter of the air duct cross-section, duct devices are selected and installed.

Important! Exhaust ventilation with artificial air movement more boiler safe, than with natural, since the direction and strength of the air flow is controlled.

When choosing an artificial ventilation system, it is important to choose the right one calculate productivity ventilation system.

Formula: the volume of the room requiring ventilation is multiplied by the required number of times the air in the room is completely changed per hour (according to sanitary standards, this the coefficient is 3).

The obtained value must be adjusted (increased) taking into account the coefficient of overcoming the resistance of the chimney.

Artificial ventilation is equipped automatic system, allowing full control of the process. For example, the fans will turn on when the boiler is turned on.

Reference! The optimal choice for a boiler room is a combination of natural and artificial ventilation. In this case, most external factors are taken into account, since one system duplicates the otherFor example, if the electricity goes out, air circulation will occur through natural exchange.

Types by purpose

By appointment There are the following types:

Exhaust

Such ventilation systems are based on the fact that contaminated (used) air is removed from the room. Exhaust ventilation, in turn, can be both natural and artificial.

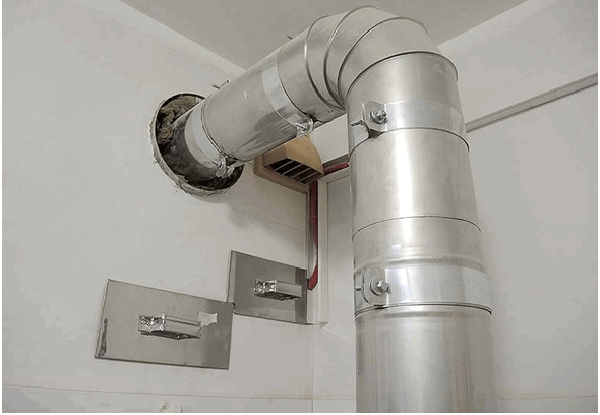

Photo 1. Exhaust ventilation pipes for a gas boiler in the heating system of a private house.

Supply

It is based on the fact that fresh air is supplied into the room. Oxygen is supplied both naturally and forcibly.

Photo 2. Supply pipes for ventilation are distinguished by the fact that they supply fresh air into the house.

Combined

In such systems, simultaneously occurs exhaust air removal from the premises and the arrival of fresh ones.

Pros and cons

Advantages and disadvantages The described types of ventilation are given in the table:

| Pros | Cons |

| Natural ventilation | |

| Air enters the room without any special investment. | Dependent on external factors that cannot be controlled (weather, air temperature, wind direction). |

| Artificial ventilation | |

| Does not depend on external factors. Additional functions such as air cleaning, heating or humidification can be used. | Costs of electricity consumption. Installation and operating costs. |

| Supply and exhaust | |

| Depending on the conditions, you can choose one of the systems that suits specific conditions. | Electricity consumption costs. The need for preliminary planning. |

| Supply and exhaust | |

| Low cost, as it does not require additional equipment. | Requires constant additional care and monitoring: cleaning, preventing freezing in winter, preventing backdraft. |

By design

By design There are different types of hoods:

Channel

Consists of air duct systems, through which air currents move.

These systems take up little space, hidden installation is possible, for example, under suspended ceiling structures, in recesses in walls or shafts.

Ductless

They operate with the help of fans installed in window or door openingsClean air coming from outside helps maintain a comfortable atmosphere inside.

Requirements in a private house

- A maximum of 2 units of gas equipment may be connected to one chimney. If there is more than one ventilation outlet, the distance between adjacent ones must be not less than 50 cm. The capacity of the chimney is limited, and failure to comply with this requirement may result in incomplete removal of combustion products from the room.

- Absolute tightness of ventilation for a gas boiler. Even the smallest leak of carbon monoxide is unacceptable and dangerous to human life and health.

- The connecting seams of chimneys must be treated only with heat-resistant sealant, resistant to high temperatures.

Failure to comply with this requirement may result in seams coming apart and the system becoming less airtight.

- Mandatory thermal insulation. Interaction of air duct elements at high temperatures may result in fire.

- Ventilation must be calculated in such a way that three times the air exchange of the entire volume of the room is carried out in one hour.

According to sanitary standards, the air in the room must be completely renewed. at least three times per hour. This is a guarantee of the normal well-being of the people there.

Signs of improper system functioning

Most modern gas boilers are equipped with sensors and automatic shutdown systems in case of malfunctions or any problems with the ventilation system.

And yet, let us outline some signs that at the initial stage they can signal malfunctions and problems:

- Reduced boiler efficiency, excessive gas consumption with low heat transfer indicates a decrease in combustion temperature, which is caused by insufficient oxygen supply or poor removal of combustion products.

- The appearance of a specific unpleasant smell of natural gas or a feeling of lack of oxygen in the room (which may indicate a build-up of carbon monoxide) indicates a ventilation leak, leak, or poor removal of combustion products.

- Boiler goes out or fails to start may indicate a lack of draft or reverse draft in the system.

Attention! All these signs require immediate intervention of a qualified technician in order to check the system and troubleshoot. If ventilation problems are ignored, there is a risk of causing harm to human life and health.

Useful video

The video shows one of the options for creating ventilation for a gas boiler.

Conclusion

When purchasing and installing a gas boiler, it is important to remember that A properly organized ventilation system is the most important requirement, ensuring the safety and efficiency of the device.