To live without fires and explosions: how to ground a gas boiler in a private house with your own hands?

Installing a gas heating system in a private home involves certain electrical safety requirements.

According to the Electrical Installation Rules (PEU) it is necessary to carry out protective grounding gas boiler.

If this is not done, a fire or explosion of equipment may occur, a threat to human life from dangerous voltage may arise. You can do these manipulations yourself, without involving outside specialists.

Grounding a gas boiler in a private house

First of all you need to choose a grounding conductor: they come in different types natural or artificial origin.

TO first type include various metal objects that are in contact with the soil, to the second - an ordinary steel conductor buried in the ground.

An artificial conductor is made on one's own or bought ready-made set.

Installation work can be carried out either under the house itself, for example, in the basement, or next to it.

Important! There can be no natural grounding heating pipe, water pipe or sewerage.

To do everything right, you need diagram, grounding requirements and tools, which will be needed during work.

How to ground a gas boiler yourself

The design of the circuit is prepared before installation.

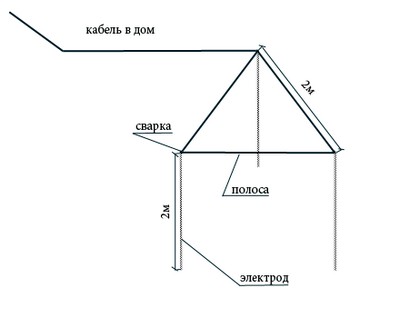

The document can be used as triangle shape, presented in the article, and figures with a large number of sides. Main - no less than two.

The more sides and electrodes there are, the lower it will be resistance.

Ready-made grounding kits usually already include a diagram.

Norms

To avoid emergency situations, a number of grounding requirements should be observed. The PUE establishes that the resistance of the circuit should be no more than 10 Ohm in normal soil and >50 Ohm in dry sand.

The following cross-section is permitted for the wire connecting the panel to the circuit:

- copper wire - not less than 10 sq. mm;

- aluminum - 16 sq. mm;

- steel - 75 sq. mm.

Tools and materials

To install the grounding system, you will need the following materials:

- electrodes, namely: metal angleto dimensions 5x5 cm or construction reinforcement with a diameter not less than 16 square millimeters;

- metal plates thickness not less than 40 cm, width - 4 cm;

- bolt connector.

To work with these materials you will need the following tools:

- welding machine, if the plates are not secured with bolts;

- shovel for digging a trench;

- sledgehammer or hammer drill;

- Bulgarian, to cut off excess pieces of metal.

Reference! Instead of a welding machine, you can use drill with metal drill bits and fasten the plates with bolts.

The process of grounding a gas boiler in a house:

- Select suitable grounding conductor. It is possible to choose between artificial and natural grounding.

- Then you should choose the right place, where the installation will be carried out. It is necessary to dig in the ground three trenches for the grounding circuit, depth about 50 cm, length not less than 120 cm each.

-

It should work triangle, into the corners of which electrodes are driven. If the ground is hard, holes can be drilled with a motor drill.

The top of the electrode should lie below the freezing depth of the soil. on average, 70 centimeters.

- Then connect the electrodes together metal plates. Some kits are welded together, others are bolted together. Plate thickness is not less than 40 cm, width - 4 cm.

- The plate from the triangle is brought out to home. It is welded to the plate bolt connector, to which the grounding wire leading to the panel is screwed.

- Grounding loop burrows into the ground.

Safely checking for proper grounding

It is recommended to check the circuit immediately during installation to ensure that it complies with the standards. two ways to do this:

- With special equipment, for example, a megohmmeter. Such equipment will have to be rented, but the result will be the most accurate.

Photo 1. Megaohmmeter model 131100, resistance measurement range from 0.1 to 200 MOhm, manufacturer - Megeon.

- With a regular socket and a light bulb. They go to the patron two wires with insulated ends. One wire is brought to zero, second — to the phase. The bulb will light up. Then the wire from zero is brought to the ground. The bulb will light up if the circuit is in good condition, flicker — if the circuit is poorly mounted, and will not light up when the ground is not working.

The verification procedure is carried out at the gas boiler is turned on.

The final inspection of the contour is carried out by representatives electrical laboratory and gas serviceBased on the results, a test report of the earthing resistances and a conclusion on compliance with the standards are drawn up.

In the future, it is recommended to check the circuit with devices. every 6 years, every year conduct a visual inspection.

Useful video

Check out the video that shows the process of grounding a gas boiler.

Security measures

Grounding of a gas boiler is a necessity for creation safety in the home. Many devices simply fail because the owners did not take care to comply with the rules. The work can be done personally or entrusted for specialists, if you don't have the necessary tools.

You cannot use a regular socket or a power filter to connect and ground the boiler. It is better to install a special device - RCD (residual current device), which will stop the equipment from working if there is a problem.