Whistling, knocking, annoying rumble! Why is the gas boiler noisy, is it faulty?

A recently purchased gas boiler works quietly, barely noticeable to a person. If during operation the unit suddenly starts making noise, then this is a direct sign of the appearance of the first malfunctions in the system.

The fan is out of order, the walls of the heat exchanger are clogged with scale, the units of the device are worn out or the boiler is incorrectly configured - all these reasons lead to the fact that the device beeps, knocks, hums, or clicks.

Content

Why does a gas boiler make noise when heating?

Exists many reasons, causing alarming noise in the gas boiler. Each malfunction requires a different approach to eliminate it.

The fan located above the burner is malfunctioning

The fan provides blowing in the system to remove and exhaust smoke, and also cleans the gas from combustion residues. Common cause Fan failures are operating time. The longer the boiler operates, the more wear and tear occurs on the system parts.

Photo 1. This is what a fan in a gas boiler looks like. Its breakdown can cause unpleasant noise coming from the heating device.

Other reasons for breakdowns:

- Fan usually located above the burner. Constantly exposed to high temperatures, the bearing grease burns out. This causes rapid wear.

- Fan filled with dust and residues from gas processing.

- Factory defect.

Reference. There are characteristic sounds that indicate a malfunction of the device. Listen to the operation of the boiler. If it makes clicking sounds at short intervals — the reason is in the fan.

For that to repair fan, the following manipulations should be carried out:

- To begin with inspect fan and clean it from the inside: the main blades are located on the inside of the housing, it is necessary to free them from accumulated dust and dirt, and then lubricate the bearings.

- If the problem has not been solved and the boiler is still noisy, you can replace valves with ball valves or install a rubber gasket.

- If the previous measures did not help, then you should reinstall coolerTo do this, you need to call a technician and replace the worn-out device with a new one.

Scale in the heat exchanger

The heat exchanger is a component of the boiler, acting as an intermediary between the thermal energy of the gas and water, which heats up from it. Because of it, scale appears and lime accumulates both on the walls of the radiator pipes and in the entire heating system.

Photo 2. Heat exchanger from a gas boiler with scale formed on it. Because of this, the heating device makes noise.

This often causes the water passage to become narrow, which causes steam and small bubbles to form in the system. Scale reduces the wear resistance of the equipment and the efficiency of the device. The breakdown is already noticeable within 15-20 minutes continuous operation of the gas boiler.

Important! An alarming sign that a lot of limescale has accumulated in the heat exchanger is a characteristic sound. Device hisses, whistles, howls like a kettle when it boils.

Deposits lead to excessive overheating of the heat exchanger walls, which causes them to warp.

To clean the device from dirt, you should flush the heat exchanger, pipes and other parts of the heating system with a chemical solution.

Reference. There are a large number of chemicals in household stores that can quickly clean any scale. To choose the right one Consult with a gas service technician.

First remove the heat exchanger itself. Then remove the casing and unfasten the pipes connected to it. The chemical solution is poured into the device for 2-5 hoursIf the design of the device is quite complex, then to remove it yourself, use a flexible hose.

Not enough water

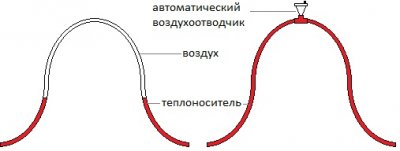

The reason for the breakdown may be air locksThey occur due to insufficient water in the heating system.

The presence of air prevents proper water circulation, which disrupts heat exchange in the heating network. Due to the lack of liquid, the boiler overheats, which causes noise.

The process of airing contributes to the occurrence of the following deviations:

- the level of heat output of the device and its sections decreases;

- circulation of the coolant is reduced or completely absent.

Common causes, due to which air enters the heating system:

- depressurization of the system during repair work on risers;

- complete drainage of water from the mechanism;

- violation of system integrity;

- consequences of repairing some components during summer scheduled preventive maintenance checks;

- preventive maintenance: replacement of heating devices, risers and shut-off mechanisms.

Important! Air lock in the heating system is the first sign that the boiler is not working properly. If there is not enough water in certain areas of the pipes, an air lock is formed. Part of the mechanism cools down, water cannot circulate properly through the system, and you hear "dull" whistle And howling in clogged sections of the pipe.

In order to adjust the unit, you need to look at the thermostat and adjust it. You should make sure that the noise is not caused by an incorrectly installed thermostat. If everything is OK, it is worth add enough water or regulate its supply and circulation throughout the entire heating system. Many water heaters have a lever installed for such cases.

If air gets into the system, use two proven ones: ways to eliminate the cause of the problem:

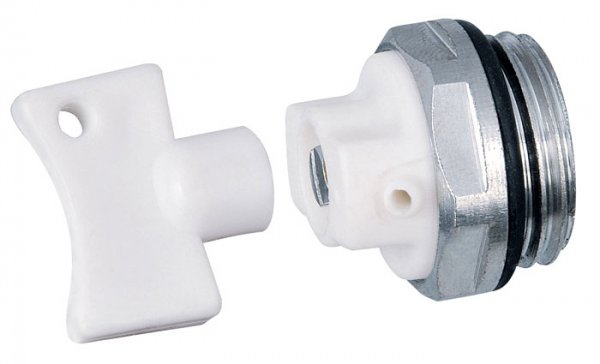

- Mayevsky crane — is a small device that is installed in the end of the heating device. It contains a special nipple, which, when unscrewed, opens access to the battery. Often, warm air accumulates in the upper part of the radiator, where the Mayevsky crane is also installed.

Photo 3. Mayevsky crane. This device helps to get rid of air locks in the heating system.

- Air separator - is a device that collects dissolved air, converting it into bubbles.

After the air has been released, fill the pipes with water and check the operation of the boiler.

Low pressure in the system

Causes of low blood pressure in the device:

- water leak from the heating system;

- prolonged power outage;

- breakdown of the expansion tank in the boiler;

- the boiler is configured or installed incorrectly;

- The boiler was selected without taking into account the load requirements.

The unit may start making loud noises due to low pressure in the heating unit. When you notice a malfunction, first inspect the system for leaks. To do this, use a napkin. Wipe the device in the joints and connections. Water forms there when the pressure in the pipes increases. The detected leaks must be closed.

The reason could be crack formation. When checking the malfunction, you should release all the water from the network, shut off the boilers and radiators, and then pump air with a compressor. You will hear a whistle in places where there are microcracks or a weak connection, due to which the pressure has dropped.

Reference. The system stops working at low pressure. Gas pressure directly depends on the water pressure in the network. When water does not pass into the boiler, the gas pressure is reduced to the minimum mark. At the same time boiler automatically turns off.

It is necessary to know the optimal indicators and regularly check the boiler condition. Auxiliary systems that control the operating characteristics of the device display values on the screens. Normal pressure 1.5-2 atmospheres.

Malfunctions occur frequently in devices with forced circulation.

If the pressure gauge indicates that the system pressure is below one atmosphere, you should try to manually add water by opening the make-up valve.

If after refilling the pressure gauge needle continues to drop, Invite an experienced specialist, since further actions without certain skills will aggravate the problem.

To closely monitor the boiler's performance, a pressure gauge is installed in the system, which collects information about the pressure level.

If the breakdown is caused by microcracks, fix the leak using tow or sealant. If the tap is to blame, replace it. If your heating system is built into the wall and no wet spots appear on it, you will have to contact specialists, since the leak can only be detected with a thermal imager.

The reason for the appearance of microcracks is wear of the heat exchanger. Occurs when the device is frequently washed with reagents that include alcohol, due to poor quality metal or hydraulic shocks with a sharp increase in pressure in the main line. In places where there are microcracks, you can see a formed layer of scale. If it is easy to remove the heat exchanger, you can try to solder them.

Attention! Bithermal heat exchangers are often impossible to repair due to their design features, which is why It's worth calling a heating system specialist.

Incorrect settings interfere with the operation of the device

The noise that appears may be caused by incorrect setup or installation of the device. In this case, you can hear how the gas valve or bypass howls. In addition, if you make a mistake during setup, the gas boiler may make noise for other reasons, for example, due to incorrect load distribution.

Reference. Working at high power, broken gas meter may thunder. This happens when the equipment power exceeds the required values. Vibration occurs due to excess pressure created by the pump.

Are you hearing loud metal-on-metal bangs as your heating structure heats up and cools down? This means that something is happening in the unit. uncompensated thermal expansionThis happens when the hanging brackets on the radiators are installed incorrectly.

Loud noises are produced by a fan that is not working properly, designed to remove combustion products.

This is happening due to bearings, the grease inside of which dries out over time. They need to be checked and lubricated periodically. The blades should be clean off the remains of soot and other contaminants.

What to do?

- If the gas valve whistles, you need to check its settings. To find out what parameters need to be set, read the configuration. It describes in detail the correct instructions for operating the heating system.

- If the pump power in the device is higher than required, reduce speed. To do this, turn the switch located under the cover on the terminal block.

- The air flow from the heating system passes through a brass air collector on the front panel. When you hear a pop when lighting a semi-automatic model, for prevention Clean the nozzle and tube of the pilot burner from dirt.

- If the automatic boiler turns on with a loud bang, you should clean ignition electrodes And adjust their position correctly.

Useful video

Watch a video that talks about possible causes of knocking in a gas boiler.

How to determine the source of noise when the device is heating up

If the boiler is humming, you can check the water level in the system yourself and top it up if necessary.

If the knocking sound is heard from the pipeline and radiators, then air has entered the system and needs to be removed. If the pump itself is noisy, then a manufacturing defect cannot be ruled out. In this case, you need to install a new element from the manufacturer.

Do it on time preventive cleaning heat exchanger from scale. Periodically adjust the gas supply to the system - too much pressure is undesirable.

Comments

Often, malfunctions and noise arise due to scale and deposits in the parts of the system through which water passes. The appearance of deposits depends on the composition of the water. We have chalk mountains in the area, the water is chalky, so I flush for prevention once every year and a half.

Work with the solution wearing gloves and a mask. Pour for two hours. It is practically insoluble in water, but dissolves blockages well.