Are the pipes cracking angrily and heating poorly? It's time to flush the gas boiler and its heat exchanger

The heat exchanger of a gas boiler is a structure inside which water, which is a coolant, circulates.

The water is heated by thermal energy and distributed throughout the heating system. Heat exchanger made from metals, conduct heat well: cast iron, copper, steel.

Content

When does a gas boiler need to be flushed?

To understand whether a gas boiler needs cleaning, it is important pay attention to the following points:

- increase in time to heat the room (with the same air temperature outside);

- difficult work circulation pump;

- pressure drop water from the tap - if a double-circuit boiler is used;

- uneven heating batteries, pipes and other heating elements;

- overheat heat exchanger - occurs when the return of return water is difficult;

- crackling, micro explosions and other sounds that shouldn't be there.

Attention! In a country house or cottage, the gas boiler operates around the clock throughout the winter period. This means that flushing should be done annually at the end of each heating season.

Boiler cleaning methods

Exists two ways cleaning the boiler from scale and dirt:

- Disassemblable — is a method that requires disassembling the unit. When using it, the contaminated parts of the boiler are dismantled. These components are then either placed in a container with a reagent for a few hours and are cleaned mechanically, or another cleaning method is used. It all depends on the degree of contamination. Then the elements are put back in their places.

- Non-disassemblable - cleaning is carried out without dismantling the parts, directly on site. This procedure is best done using a booster.

In-place cleaning is carried out as follows:

- the boiler is disconnected from the fuel supply;

- is cooling down;

- water is drained;

- the device is disconnected from the heating system;

- the booster is connected;

- the pumping of liquid reagent begins (2-6 hours);

- At the end of this process, the cleaning liquid is drained;

- the boiler is washed with water;

- is drying;

- reconnects to the heating system.

For best results, follow the procedure repeat several times.

Dismantling and cleaning of parts

When choosing a disassembly method in order to prepare gas boiler for cleaning, it should be disassembled:

- turn off the gas supply;

- disconnect the wires from the gas valve;

- unscrew and remove the boiler door;

- disconnect the wire leading to the piezoelectric element;

- detach the thermocouple and injectors (required) make marks for the immersion depth of the injectors into the burner);

- disconnect the fuel supply pipe;

- remove the burner, unscrew the nuts and remove the top cover.

Key points cleaning of parts:

- Igniter. To clean it, you need to turn off the gas, remove the pilot light, clean it with a metal brush, blow it out, and put the pilot light back in place.

- Burner and nozzles. To clean them, you need to shut off the gas supply, remove the burner from its place, mark the location of the nozzles, then carefully unscrew and clean the nozzles with a brush, and the burner with a brush. After this, it is advisable blow out the burner hole using pumping equipment, which is at hand, then the nozzle should be inserted back, focusing on the mark, after which the burner is installed in its place.

- Heat exchanger requires cleaning both inside and outside. Water circulates inside, and the main blockages are located there. Outside, the heat exchanger gets dirty with soot, which negatively affects its operation. You can clean the device from soot mechanically; a scraper, metal brush, or brushes will do for this.

Important! When cleaning, do not use a tool that has sharp edges, otherwise the boiler parts may be damaged.

Cleaning stages heat exchanger:

- gas supply is cut off;

- the heat exchanger is removed;

- cleaning is carried out with any mechanical tool;

- the heat exchanger is installed in place.

How to flush a heat exchanger with your own hands

Flushing of the heat exchanger can also be carried out in several ways.

Mechanical method and rinsing with secondary cleaning

Manual cleaning means cleaning at home. This is the simplest method of processing. It includes:

- Mechanical cleaning - involves removing blockages from the heat exchanger using tools: brushes, metal brushes of different sizes, a hammer (rubber or wooden).

- Flushing the heat exchanger in active solutions followed by mechanical cleaning. Some experts consider this method more appropriate due to its effectiveness, especially for dual-circuit boilers.

Stages manual cleaning:

- Study the documentation for the device.

- Disassemble the boiler so as to gain access to the heat exchanger. Before doing this, disconnect the unit from the power supply (if any), disconnect it from the heating system pipes and the gas supply system.

- Remove the heat exchanger.

- Soak it in a solution of active elements, for example, hydrochloric acid. The solution should be weak so as not to damage the device. After soaking, salt deposits are easily removed.

- Clean with metal brushes, pipe cleaners or a vacuum cleaner.

- Rinse with water and dry.

- Return the heat exchanger to its original place.

Descaling with improvised means

You can flush the heat exchanger at home using available tools.

Principle such:

- A container is taken volume 15-20 l. Cut out in the lid 2 holes, to which the hoses are connected.

- The container is filled with a cleaning solution. The following are used as it: chemicals (acids), diluted with water. You can take citric acid or vinegar 9%. To prepare, dissolve 20 g citric acid in a liter of water. Based on this proportion, the required amount of liquid is prepared.

- These same hoses are connected to circulation pump.

- The pump itself is connected to the heat exchanger pipes on both sides (feed return flow). The result is closed systemThe solution circulates inside the system, cleaning the heat exchanger from the inside.

This type of flushing is done using a disassembly method at home using available tools.

With the help of chemicals

For such processing they use booster and chemical compositions, designed to clean boiler parts. A booster is also used here, only not a homemade one, but one bought in a store, certified, designed specifically for these purposes.

The booster hoses will connect to two heat exchanger pipes, then the movement of chemical elements inside the closed system occurs.

Factory-made boosters are equipped with heating components, which allows reagents heat up. And this, in turn, speeds up the cleaning process.

This procedure can be carried out both in a disassemblable and non-disassemblable way. The event lasts from 2 to 6 hours.

At the end of the procedure, the reagent is removed and poured into the heat exchanger. neutralizing substance it. After this, the heat exchanger is washed with water and dried.

The main disadvantage method - the use of active chemical elements, the impact of which negatively affects durability heat exchanger. If it is chemically cleaned frequently, it may fail earlier.

Reagents for dry cleaning:

- Adipic acid — a reagent that is diluted in water, observing a certain concentration. It is an active substance that can soften salt deposits inside the unit. The reagent is pumped in after the heat exchanger has been dismantled and cooled. After cleaning, the device is washed with water and dried.

- Sulfamic acid works on the same principle: it requires dilution with water and is fed into the heat exchanger under pressure. After exposure to this substance, salt deposits, scale and other contaminants soften and are easily removed.

Photo 1. 25 kg package with sulfamic acid 99.5% in powder form for dilution in water.

- Gel for cleaning boilers (not an acid) perfectly cleans metal elements from scale, dirt, salt deposits. After processing with this substance, rinse the heat exchanger with clean running water. The gel has a huge advantage over other reagents. It has a soft, gentle effect on metal elements. At the same time, the cleaning quality is not worse.

Advice. Since this method uses active chemicals, you should be careful when putting on rubber gloves and mask, observe safety regulations.

Hydrodynamic method

This is a method of cleaning the boiler. does not require disassembly. Its principle is that water is pumped into the system. Sometimes an abrasive filler is added to it. Then pressure is building. During the process of exposure, the speed of liquid movement increases, due to which cleaning occurs. This contributes to the destruction of salt deposits, dirt and scale inside the system.

Important! During hydrodynamic cleaning the critical pressure level must not be exceeded, as this may lead to burst pipes!

This procedure It is not recommended to carry out this on your own. It is better to entrust hydrodynamic cleaning to professionals who have a certificate and permission to work with gas equipment.

Assembling the equipment after cleaning

During the assembly process all the parts return to their places in reverse order.

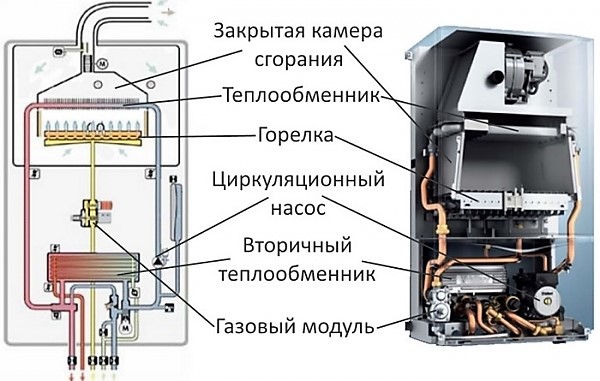

Photo 2. Diagram (left) and image of the internal structure of a gas boiler (right). The main parts are indicated.

The main point here is preventing gas leaks after assembly. In order to control this, it is necessary to carry out soaping of connections. Check the tightness of the fixing elements only after turning on the gas boiler.

Important! At reverse assembly the pilot burner should install a new gasket. The ignition electrode connection is made only manually, it is not recommended to use the key.

Useful video

Watch the video to see how you can flush a gas boiler heat exchanger with a check valve at home.

Selecting a heating appliance cleaning option

When choosing a boiler cleaning method the financial issue is of decisive importance, that is, the procedure is expensive. If funds are limited, you will have to use improvised materials and clean the boiler at home. If you have the means, you should not skimp on cleaning. It is better to use services of professionals.

Comments