You can save money, but be careful: DIY gas boiler repair instructions

Gas boiler complex mechanism. It can be divided into 3 main parts: electronics, gas pipes and burners, heat exchange unit (pump, tank, fan). Only the last part can be repaired independently.

Attempts to restore the first two parts, without proper skills, will lead to final breakdown boiler, gas leakage and other negative consequences.

Content

Reasons for breakdowns of wall-mounted or floor-standing gas boilers

Gas boilers rarely break downThis happens as a result natural wear and tear equipment, or because of factory defectOther cases of breakdowns are necessarily associated with the following factors.

Contaminated water in double-circuit

The boiler can break down due to water. At risk, first of all, are double-circuit devices used not only for heating, but also for hot water supply.

The thing is that rust from the pipeline, other fractions, clog the thin tubes of the heat exchanger over the course of a year.

Avoiding problems associated with water quality will help coarse filter. It is installed during installation. on the feed pipe liquids. For greater safety, you can add to the system fine grain filter, or install a complete cleaning system.

Electricity is the source of the problem

Household appliances are resistant to voltage drops and shutdowns electricity. But a gas boiler is a more delicate piece of equipment. A power surge will cause the boiler to turn off or the electronics to break down. A malfunction of the device or a power outage will cause the heating pipes to freeze.

To avoid tragic consequences, install at least one of the additional devices.

- Stabilizer — a device that will solve the problem of voltage surges. Its size is small, it is installed both in an apartment and in a private house.

Photo 1. Electronic voltage stabilizer Resanta Lux for heating boiler. The device is mounted on the wall.

- Uninterruptible power supply. Will equalize the input voltage. Will allow the boiler to work for some time without electricity. Suitable for use both in an apartment and in a house.

- Gasoline generator. Does not affect the stability of the network, but can save during a long power outage. Used only in the private sector.

Attention! When purchasing a generator, check to see if it is really single-phase.

Violations of installation instructions

Installation of complex equipment unprofessional will entail serious consequences. In frequent cases, the following problems occur:

- In the process of installation neglected grounding. This leads to the accumulation of static on the body of the device. When an electric arc occurs, the boiler automation often fails.

- After installation did not release air from the systemThe resulting blockage will lead to a rupture of the coolant pipes and a breakdown of the pump.

- Violations in the harness gas boiler systems with a cast iron heat exchanger will cause a split in an important part of the device.

terms of Use

If the installation of the gas boiler is done correctly, operational problems arise only due to weather conditions. In the cold winter, the desire to warm up pushes people to use the boiler in the maximum mode. The equipment can withstand such conditions, but the gas system cannot. A decrease in fuel pressure leads to interruptions in the operation of the device. The automation begins to turn off the boiler. The problem is that this can't be called a breakdown and it won't be possible to eliminate it.

Possible malfunctions and DIY repair methods

Any malfunction of a gas boiler should be dealt with by a specialist. However, it is not always possible to use the services of a specialist, and breakdowns can be trivialLet's look at problems that can be solved independently.

The house smells like gas

Usually the smell of gas appears when it leaks from the threaded connection of the supply hoseIf there is a smell in the room where the boiler is installed, you need to open the window and turn off the boiler. Then follow the instructions:

- Prepare the necessary things: soap solution, FUM tape, open-end or adjustable wrench.

- Apply solution for all threaded connections. If bubbles start to inflate, the leak has been found.

- Close the gas valve.

- With the key expand connection. Wind up on external thread FUM tape and put it all back together.

- Reapply the solution and resume the gas supply.

- If the leak is fixed and the gas smell is gone, remove residues solution.

Attention! When the leak location cannot be found, turn off the gas, call a specialist.

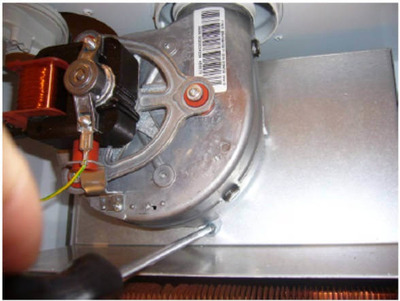

The fan is not working

If during the operation of the boiler the sound emitted by the turbine has disappeared or decreased — indicates a malfunction of the blower fan. Repair will require: screwdriver, new bearing, rag, thick grease.

- Necessary turn off boiler and turn off the gas.

- Remove the turbine.

- With a rag clear from turbine blades dust and carbon deposits.

- Inspect the electric coil fan for blackening. If everything is OK, proceed further or replace the fan.

- Disassemble the fan housing. The turbine shaft is mounted inside bearing, his needs to be replaced. Some fans have a sleeve instead of a bearing. In this case, it needs to be lubricated.

The turbine may also not work due to low voltage network or control board malfunctions. The first can be eliminated with the help of a stabilizer, but the second can only be eliminated by calling a specialist.

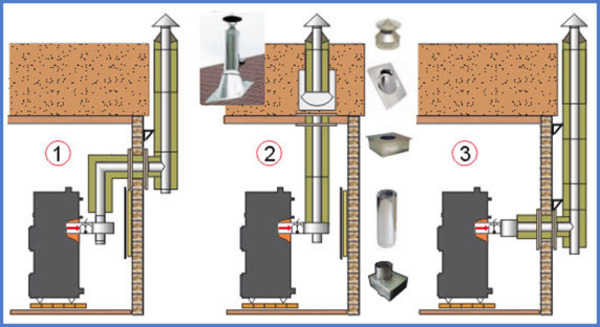

The chimney of the floor-standing boiler is clogged

Problems with the chimney arise only at boilers floor type. This is due to its size and vertical position. Wall-mounted devices do not require chimney cleaning.

Chimney consisting from metal parts, cleaned with a metal brush. It must be disassembled and the accumulated soot mechanically removed. Whole The chimney is cleaned with special vacuum cleaners or chemicals. But for this you need to call a professional.

Photo 2. Three ways to arrange a chimney for a floor-standing gas boiler. The first option is the most difficult to clean.

High temperatures

Boiler overheating is associated with contamination of the heat exchanger. To clean the device you will need: special hydrochloric acid solution, adjustable wrench, FUM tape, metal brush. Then follow the instructions:

- Turn off the boiler, turn off the gas and water.

- Remove the heat exchanger, using an adjustable wrench.

- Clear it with a brush.

- Through the pipe pour into the heat exchanger acid solutionIf foam appears, it means there is a lot of scale inside.

- Pour out solution and repeat procedure.

- Rinse.

- Install back, preliminary wrapping all threaded connections with FUM tape.

Sensor malfunction

Problems usually arise with combustion electrode. If the burner flame goes out after a few seconds, and the boiler gives an error, then the problem is in the combustion sensor. Turn off the boiler, shut off the gas.

To repair the electrode you will need sandpaper, with the help of which the sensor probes are cleaned, without removing it. If the damage remains, the sensor is changed.

Self-power off

There are two problems, which lead to spontaneous shutdown of the boiler. The combustion sensor is broken or the chimney is clogged. Repair of both faults is described above in the article.

Useful video

Watch the video, which talks about the malfunctions that occur during boiler operation.

At the end

Most boiler breakdowns can be fixed independently, but This does not mean that you should neglect the help of a specialist. Gas equipment is potentially life-threatening.

And also don't forget about technical maintenanceCleaning the heat exchanger and chimney will protect against possible breakdowns.

Comments