What is their real essence? Gas heating boiler diagrams

Gas boiler is an irreplaceable device for heating a house or apartment up to 500 sq. m.

Having spent on the purchase 10-30 thousand rubles, you can count on an uninterrupted supply of heat and regular heating of hot water for bathing.

Content

Types of gas boilers for heating: condensing, convection and others

Boilers running on natural gas, there are different types: floor and wall-mounted, with open and closed combustion chambers, double and single-circuit, condensing and convection (the former are more powerful and have high efficiency).

Advantages of gas heating:

- heating of large areas (ideal for cottages, summer houses, country houses);

- electric or piezo ignition;

- continuous gas supply;

- high efficiency - minimum 90%;

- electronic control system (including via the Internet in expensive models);

- automatic resumption of operation in case of voltage drop;

- low maintenance costs;

- savings on utility bills;

- minimal risks during operation.

Boiler models differ by power, security systems And ease of management.

Spent fuel removal is organized through the chimney or by forced draft through a small coaxial pipe. A fan, which is present in many models of forced draft boilers, also helps in removing waste. The device is started using an electric or piezo ignition. In the first case, automatic switching on is possible when the voltage in the network drops, in the second case, it is not.

Placement: wall, floor

Wall hung boilers represent a structure weighing from 30-50 kg, which is attached to the wall. Due to this, the equipment does not interfere with anyone and actually blends in with the decoration.

Photo 1. Wall-mounted gas boiler with a connected water circuit. A boiler for heating water is also connected to the system.

Wall-mounted devices are characterized by power from 12-42 kW. Such boilers are capable of heating the territory up to 350-400 sq. m. Due to their light weight, the boilers are easy to install and do not cause any inconvenience to the owners. Heat exchangers in such devices are usually made of lightweight copper tubes.

Wall mounted boilers are divided into types:

- regular models;

- with modulating burner.

The boiler's modulating burner allows use fuel economically And spend less money on utility bills. Wall-mounted boilers are divided into models with forced and natural draft, that is, with a fan and a chimney. If there is no opening for a chimney in the room, you must choose the first option.

Reference. Cost of wall-mounted boilers - from 14 thousand rubles. For this price you can buy mainly domestically produced devices of low power. The average price of good models from foreign manufacturers not less than 24-35 thousand rubles.

Floor standing boilers. These are heavier units (up to 120-200 kg), which are installed on the floor. They are mainly chosen for heating large rooms and are installed in mini-boiler rooms or utility rooms. The considerable weight of the boiler is due to the fact that the heat exchanger is made of heavy materials, such as cast iron.

Some boiler manufacturers offer narrow units that are no wider than 35—45 cm. The average power range of such devices is from 12 to 108 kW, however, there are boilers in which the power reaches 1000 kW.

You can choose floor-standing gas models:

- with forced draft burners;

- with atmospheric burners.

The first ones are more expensive due to energy consumption and high efficiency. Boilers with atmospheric burners cost less and operate almost silently. The floor-standing device is characterized by such elements as a draft sensor, thermostat, a well-thought-out safety system in case of a drop in temperature, voltage in the network, overheating.

The cost of floor-standing boilers of Russian production is from 10 thousand rubles. High-quality units with a lot of additional functions from foreign companies cost not less than 35-42 thousand rubles, and elite models with increased power - up to 200 thousand rubles.

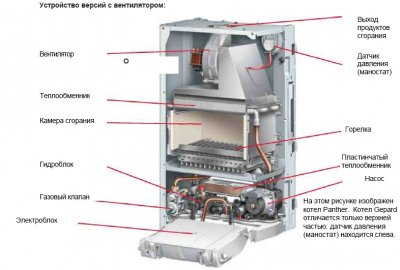

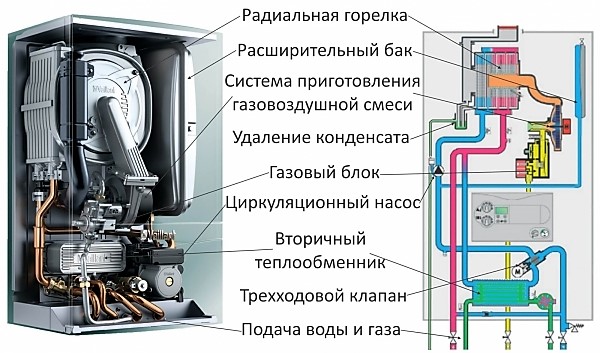

Device diagram, dimensions

Any modern boiler consists of a gas burner, inside which there are nozzles, through which fuel is supplied to the combustion chamber.

An integral part of the unit — a heat exchanger, inside which there are pipes with a coolant.

Number of heat exchangers depends on the type of equipment: for a single-circuit (only for heat) it is one, and for a double-circuit (for heat and water heating) they there may be two.

The boiler structure includes a circulation pump and an expansion tank for removing the coolant. The device is controlled using an electronic system.

Wall-mounted boiler models differ from floor-standing boilers not only in the way they are installed. They are lighter in weight, have a lower power level and produce almost no noise during operation. Double-circuit wall-mounted boilers heat water up to 55-60 degrees CelsiusThey have electric ignition and a modulating burner.

Technical specifications wall-mounted boiler:

- open or closed combustion chamber;

- heating area — up to 240-400 sq. m;

- height - up to 70-74 cm, length - 30-31 cm, width - 40 cm;

- average power - from 11-25 kW;

- productivity - minimum 10-15 l per minute (for dual-circuit models);

- gas consumption indicators - minimum 2.73-2.78 m³/hour;

- tank capacity — 6-10 l;

- safety valve and freeze protection;

- Efficiency minimum 90%.

Modern wall-mounted boiler models have bithermal heat exchanger And draft presence sensor. They are controlled by a liquid crystal display. The safety system is also important in this boiler: protection against overheating, lack of water, scale and pump blocking.

Photo 2. Diagram and image of the internal structure of a double-circuit condensing gas boiler. The main parts are indicated.

Another important component is modulating burner and fan. Thanks to them, you can change the boiler power and automatically increase its efficiency. It is desirable that the boiler body is protected according to IPX5D standard in case of leaks and other damage.

Floor standing boilers require complex installation and are considered safer to operate than wall-mounted ones. They are larger in size and may produce noise during operation. Exceptions are possible only if the boiler is equipped with natural smoke exhaust and no circulation pump. Smooth switching on also plays a role, which can be very quiet or vice versa.

Double-circuit floor-standing boilers are capable of heating water to a higher temperature than wall-mounted boilers: up to 80-90 degrees. The equipment has built-in safety valves, minimum pressure relay, and draft stabilizer.

Technical specifications floor standing boiler:

- open or closed combustion chamber;

- heating area — up to 450-1000 sq. m;

- height - up to 100 cm, length - up to 45 cm, width - up to 52-60 cm;

- average power - from 7-50 kW;

- productivity - minimum 6-15 l per minute (for dual-circuit models);

- gas consumption indicators - minimum 0.94-1.45 m³/hour;

- tank capacity — 6-10 l;

- operation of boilers in cascade is possible;

- safety valve and freeze protection;

- Efficiency minimum 91-93%.

Floor-standing or, as they are also called, stationary boilers equipped with an LCD display, where you can read the service menu and error codes.

The presence of flame in the boiler is monitored using an ionization sensor. The pilot burner of the boiler is started using a piezo ignition or electric ignition.

Boilers can be operated in parallel connection to a single heating system. Safety is achieved thanks to the automation of all management processes.

Materials of manufacture

The most expensive boilers are those with heat exchangers made of cast iron. This is because cast iron components last longer and are resistant to corrosion and thermal stress. Heat exchangers are highly valued made of stainless steel and copper, treated with an inhibitor composition. Boiler models with components made of made of aluminum.

The material for the boiler must be as resistant as possible to cracks and rust. The service life of high-quality heat exchangers is at least 20-30 yearsThe cast iron components of the boiler have a special crystalline structure to ensure uniform heat flows.

Traction type

Wall-mounted and floor-standing boilers come with different types of draft.

Natural traction requires the installation of a chimney. Air is drawn directly from the room, thanks to this the combustion process in the chamber is maintained boiler.

Draft occurs when the air pressure in the chimney drops.

Technical parameters:

- highly sensitive automation;

- draft sensor;

- pump anti-blocking;

- mid power range - from 11 to 35 kW;

- cast iron or copper heat exchanger.

Boilers with such draft have in their design open combustion chamber. Atmospheric burners are used to process gas. Boilers can be made of a variety of materials: from cast iron to copper with an aluminum layer.

Attention! Natural draft devices are less dependent on electricity. Boilers with such a system are cheaper than those with forced draft. But indoors waste products (carbon monoxide) may accumulate, which requires periodic ventilation.

Forced draft provided in boilers with a closed combustion chamber, not tied to a chimney (a small pipe is enough to remove the processed gas). Such devices are called turbo boilers. In this case, the draft is provided by an additional fan - a smoke exhauster. Waste is removed to the street through a coaxial pipe mounted in the nearest wall.

Technical parameters boiler:

- coaxial pipe;

- mid power range - up to 24 kW;

- bithermal heat exchanger;

- closed combustion chamber;

- compact dimensions.

The boiler has draft sensors and gas fan burners. Due to a more modern system, boilers with forced draft are more expensive and have higher efficiency. In addition, turbo boilers are less expensive to install, since all that is required is to run the pipe outside.

Atmospheric boilers, operating principle

This type of natural draft devices imply the presence of an atmospheric burner in the form of a set of nozzles through which gas comes out.

Air enters the boiler from the room and intensifies the flame, consuming less fuel than conventional models.

Technical parameters boiler:

- high level of efficiency (more than 90%);

- the ability to operate at reduced gas pressure;

- low noise level;

- easy installation and maintenance;

- operation at low modulated temperatures.

The most preferred boiler models are those with the following power: up to 100 kW, as this allows them to operate in a wide range. Atmospheric boilers are more affordable, but their service life is short. Often such devices are made with cast iron heat exchangers, including cast eutectic cast iron.

Atmospheric boilers are dependent on draft and supply and exhaust ventilation systems. With regular preventive maintenance, the equipment serves at least 10-20 years.

How does a turbocharged device work?

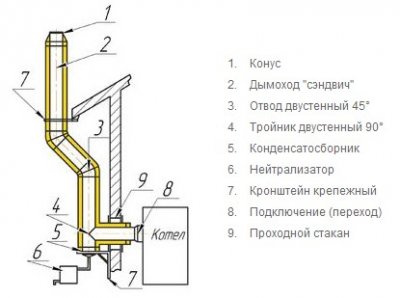

Turbocharged boilers work by means of forced draft. They must have a closed combustion chamber, into which air is supplied through a fan. An important element of the device of such a boiler is a coaxial chimney made of two pipes of different diameters. The combustion chamber in the boiler is usually lined with copper or cast iron.

Photo 3. Coaxial chimney, brought out from the outside of the building. Such a device is used for turbocharged boilers.

Technical parameters of the boiler:

- Efficiency at the level 93%;

- average power - 6—25 kW;

- mass release of combustion products (G20) — 56 kg/h;

- light weight (from 30 kg);

- gas consumption - 2.4 m³/hour.

This quite a quiet boiler, which will easily fit into any interior due to its modest dimensions. The pipe can be sold as a set or ordered separately. A coaxial chimney consists of an inner pipe that removes smoke and an outer pipe with a larger diameter. The chimney can be installed vertically, horizontally and on an inclined plane. Thanks to this device, fuel is used economically. All waste is removed immediately and does not accumulate in the room.

The volume of the expansion tank in such a system is at the level 6-15 liters. The maximum heating temperature can reach 85 degrees.

Burner type

Burners in boilers can be atmospheric or forced-draft. The second option is considered more powerful and expensive. The choice of burner type depends power of equipment and yours gas costs.

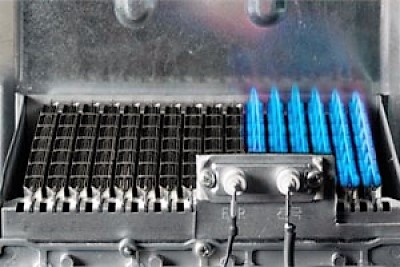

Atmospheric or conventional burners do not require a fan and are a tube with holes for gas to escape.

The burner consists of a nozzle, a head, an ejection tube and an air regulator. Both wall-mounted and floor-standing boilers are equipped with them.

The gas, mixing with the air in the room, ignites using various ignition systems.

You can choose burners:

- single-stage - with one operating mode;

- two-stage - with two modes;

- modulated - easily adjustable.

Important! It is precisely by choosing the burner operating mode that energy consumption is achieved. The most efficient option of those proposed is modulating burner, which changes depending on the temperature setting of the coolant. Units with such a burner are quite expensive, but the costs are fully justified.

Technical parameters of boilers with atmospheric (conventional) burners:

- average power level;

- silent operation;

- light weight construction;

- modest purchase and installation costs.

The heat exchanger in atmospheric technology is rectangular, and the burner follows this shape. This increases the heating level and the efficiency of the device. Boilers with an atmospheric burner have only one drawback - they have low power, which may not be enough to heat a large house or apartment. If we compare the efficiency, it may also be less than that of models with forced draft.

Forced-draft burners are considered more complex in their design. They are made with a fan that forcibly pumps air supplied in portions. A closed combustion chamber is always made for them.

Photo 4. Diagram of the forced-draft burner for a gas boiler from the manufacturer Viessmann.

Technical parameters of boilers with forced draft burners:

- high efficiency - minimum 95%;

- environmental safety;

- no dependence on line pressure;

- the ability to choose a model (the burner is usually purchased separately).

Reference. The advantage of this type of burner is the ability to adjust the gas flow power. This results in higher efficiency, than in atmospheric models.

Forced-draft burners can be purchased separately, unlike atmospheric ones. Disadvantage of forced draft burners — large weight of the boilers, increased noise level and very high price in comparison with the simplest atmospheric units.

Features of ignition

According to this characteristic, gas boilers are divided into those that are ignited by electricity and models with piezoceramic ignition.

Electronic ignition. This type of boiler ignition is considered easier than piezo ignition. The device operates using mains voltage. The microprocessor supplies operating voltage to the combustion zone, and the boiler switches to operating mode.

To start the boiler, it takes just seconds. Expensive models can be started immediately after switching off (without purging). The boilers have a sensor that ignites the gas when necessary.

Boilers with piezoceramic ignition. This type of device lights up automatically: using a button. Without human intervention ignition impossible. This does not mean that this type of device is not convenient, it just has a different mechanism of action. Most of all, piezoceramic ignition is similar to the operation of a lighter, which is often used to light a gas stove.

Useful video

Watch the video, which talks about the features of choosing a gas boiler for heating your home.

Individual approach to choosing a heating and hot water boiler model on gas

Modern boilers are so advanced that they can be controlled using a remote control or telephone, are protected against power surges and are not afraid of overheating or freezing.

Each model has its own advantages and disadvantages, you need to choose a boiler taking them into account, as well as based on the required heating area.

Boilers are considered the most expensive with forced draft And the ability to modulate fuel consumption. These are usually dual-circuit models that instantly heat water for bathing. Such boilers have a convenient electronic control system via a remote control and electric ignition.

The most affordable single-circuit boilers of small capacity with a conventional or atmospheric burner. A chimney must be made for them. Most often, piezo ignition is provided in the devices, the service life of such devices does not exceed 10-15 years.

Comments

- gas;

- cold water;

- hot water outlet;

- hot water outlet for heating;

- heating return;

Everything is simple - forced circulation is in place. Valves and filtration are installed (mud collectors are installed on the heating "return" and cold water supply) ALL on eco-plastic, soldered. An alkaline filter is also installed, a magnetic filter on the supply.