When and why is it better to buy a solid fuel boiler? Main selection criteria

You are viewing the section Solid fuel, located in the large section Boilers.

Solid fuel Boilers are devices for heating rooms, the process of heat generation in which occurs during the combustion of solid fuel.

The equipment operates on coal, firewood, peat, coke, special granules (pellets).

This type of heating is used in the absence of a gas pipeline or as a backup heat source.

Classification of solid fuel boilers

Devices that run on solid fuel are classified according to their intended use, material of manufacture and operating features.

By purpose of use: photo

Depending on the type of premises that need to be heated, a solid fuel appliance can be:

- industrial;

- household.

Household heating appliances

Domestic boilers are installed in private houses, summer cottages and bathhousesThis equipment is compact, lightweight and has a laconic modern design.

Photo 1. Household steel solid fuel boiler model Standard, power - 10-50 kW, manufacturer - "Kordi".

Water is used as a heat carrier, which is poured into the pipe system. Firewood or coal is supplied manually, loading is necessary once every 4-6 hours depending on the type of fuel.

Photo 2. Household solid fuel pellet boiler model 4M, two fuel loading modes, manufacturer - "Retra".

Power of domestic boilers: 150—2500 W. Efficiency: 85%. Exhaust gas temperature: 110—280 °C with the ability to adjust it yourself.

Industrial boilers

Solid fuel boilers are successfully used in woodworking and agricultural industries. In the process of heating premises, such enterprises dispose of waste, which is economically beneficial.

Photo 3. Industrial solid fuel boiler model Q MAX Eco, KAD - 92%, manufacturer - "Heiztechnik".

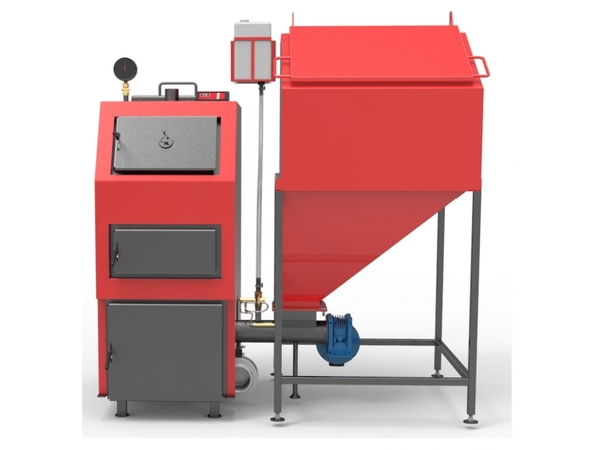

Industrial equipment that runs on pellets or briquettes is equipped with an automatic screw system for feeding pellets into the firebox.

Heating devices intended for industrial use are large in size, their weight is from 400 kg, power — from 2500 W. Equipment efficiency: 90-98%. Exhaust gas temperature: 15 —280 °C.

Material: cast iron and steel

Heating devices for domestic or industrial use are made from steel and cast iron.

Steel

Steel boilers are made from sheet steel using welded seams. The appearance and size of the equipment depends on its power. Devices made of such material are lightweight, easy to install, and inexpensive. They are characterized by high efficiency and resistance to sudden temperature fluctuations.

Improved models include: ash removal mechanism.

The service life of steel boilers is shorter than that of cast iron boilers, as they are subject to corrosionDeformed and rusty devices are not repaired.

Cast iron

Such boilers are not inferior to steel ones in terms of efficiency in generating thermal energy.

Positive properties of cast iron equipment:

- strength and durability (service life more than 20 years);

- slow heating and the same cooling down.

The heat exchanger and combustion chamber are a prefabricated structure with the ability to replace a failed section.

Ash removal is done with the help of pokers.

Important! Cast iron does not tolerate temperature changes. over 20 °C, the material begins to crack.

By combustion zone

Boilers are distinguished according to this criterion upper and lower combustion.

Top burning boilers

The design of such heating devices ensures long-term combustion of fuel. A large amount of it is loaded into the firebox at once. It starts to burn from the top, the air supply is also from the top. As the coal burns out, the flame moves to the lower layers. Solid fuel burns gradually, one layer after another.

When the temperature in the firebox rises up to 450 °C starts to act pyrolysis. The smallest remains of combustible substances continue to smolder together with the released wood gas. The use of fuel is practically waste-free.

Such boilers are produced with a capacity of 800-4000 W. Equipment efficiency: 85-94%.

Reference! The combustion time of a single-loaded fuel in such boilers is 30 hours on wood and five days on coal.

Bottom burning heating devices

In bottom-burning heating devices, fuel combustion occurs in the lower layer of the load grate bars.

The flame is supported by air coming from the primary air damper.

The combustion of volatile fuel is provided by the secondary combustion zone. Here they are located refractory concrete slabs to maintain a constant temperature.

The boiler power and the duration of combustion of one fuel load are regulated by the intensity of the air supply.

A single load of coal burns in 2-8 hours.

Selection criteria

When choosing a heating boiler, the buyer is guided by what is needed power to heat the required area of the room. Another criterion is the preferred view fuel. In addition, the purpose of the boiler is taken into account - the main one, a spare one, for permanent use or in case of interruptions in gas supply.

Fuel used and its consumption

The types of solid fuel differ cost, combustion duration, storage requirements.

Benefits of heating coal in its environmental friendliness and the renewable nature of this resource.

Long-burning boilers operate on hard and brown coal and do not require additional fuel loading for several days.

Approximate consumption of brown coal - 4 tons per season when the boiler is operating on one load - 5 days.

Modern models wood burning Boilers with lower combustion require two - three bookmarks per day, top burning - one fuel load per day. Firewood consumption 6-7 tons for the heating season.

For boilers with automatic feed fuels are used pellets and briquettes, which are made from waste from wood production and processing industries. Such fuel is effective, it will be required 5-6 tons per season, lasting 5 months. Pellets are easier to store than other types of fuel, they do not take up much space and can be stored in bags.

Number of contours

?

?

Boilers are manufactured single-circuit and double-circuit.

The single-circuit device is designed for heating only premises. Double-circuit — for heating and water heating.

If the problem with hot water supply is not solved in any other way, then a double-circuit boiler will be required.

Loading method

Heating equipment is classified according to the loading method. with manual loading or automatic fuel supply.

Automatic loading is possible for pellets, briquettes, small chips and fine coal. Fuel is placed in the boiler loading bin, on which the device will operate for a week. Such equipment is expensive, therefore it is not available to a large number of consumers.

Manually loaded boilers are less expensive but require constant attention to maintain heat.

Equipment power

The required capacity of the heating system is calculated taking into account the following criteria:

- area of the premises;

- ceiling height;

- wall insulation;

- climatic conditions of the area.

Attention! When installing dual-circuit boiler it is necessary to take into account that a significant amount of thermal energy is directed to heating water.

Additional features

Modern devices are equipped with functions that make their use much easier:

?

?

- system regulations with overheating protection;

- remote controller to control the boiler remotely;

- temperature and pressure sensor;

- protection from freezing;

- protection from ingress of combustion products into the room;

- opportunity to work on low quality fuel;

- water tank, boiler.

Devices equipped with additional options are more expensive than their classic counterparts.

Dimensions of the structure

The size of the device that will be optimal for installation is determined boiler room area.

The boiler is installed in such a way that the distance from its body to the walls is not less than half a meter. The standard distance from the firebox door to the opposite wall of the boiler room is not less than 130 cm.

Useful video

Watch the video to learn about the rules for choosing a solid fuel boiler.

Pros and cons of using for heating

Advantages:

- Autonomy device and independence from public utilities.

- Several fuel options to choose from.

- High efficiency, efficient heat transfer.

- PEasy and fast installation equipment.

- Available price.

Flaws:

- The need for creation safe conditions for storing fuel.

- Frequent technical maintenance and continuous monitoring of work.

- Time costs for loading firewood or coal.

- Difficulties with temperature control using a damper.