Proportions of mortar for brickwork. Let's not let the stove fall apart!

A well-built stove serves for decades and does not require major repairs.

When creating such devices, several types of solution are used: clay, lime, lime-cement and cementSand is added to all mixtures.

The main part (body) ovens are often laid out using clay mortar, for foundation The craftsmen use cement. For chimneys cement or lime-based mixtures are suitable. Less condensate (soot) settles inside the chimney on the limestone masonry. Furnace mixtures can be prepared independently or purchased at a hardware store.

Content

Cement mortar for laying a brick oven

His stove makers use it for foundation and chimney, rising above the roof. Such masonry does not get wet from water. Cement has increased strength, it is not afraid of not only atmospheric, but also soil moisture, which appears in the foundation of the house during long rains and melting snow.

Photo 1. Pouring the foundation for building a stove using cement.

Compound

Several grades of Portland cement are suitable for preparing the mixture: M 300, M 400, M 500Cement is sold in bags of 25 and 50 kg, after purchase it is mixed with sand. For work they take only fine sand with particle diameter 1.5 mm and less. The sand collected in the quarry requires cleaning, which includes the following steps:

- Manual selection large stones, crushed stone, pebbles, plant debris and roots.

- Sifting the material through a metal sieve with a cell diameter of 1.5 mm.

- Sand washing. For this procedure, a net is made from a linen burlap stretched over a frame. A small amount of raw material is placed in it and watered with water from a hose, which is supplied under pressure. Dust and clay particles come out of the material. Rinsing continues until the water becomes clear.

Reference. Suitable for preparing masonry mixture quartz sand or sand mixed composition (containing quartz, feldspars, and other hard minerals).

Manufacturing: order of actions and proportions

In addition to cement, the masonry mixture contains: sand and water. A large container (tank, trough, bath) is needed for work. In order to mix the ingredients, it is necessary wooden or metal spatula, construction mixer. Large volumes of cement, sand and water are prepared in concrete mixer. Different amounts of sand are used for different grades of cement:

- 1 measure of cement M 500 and 3 measures of sand;

- 1 measure of cement M 400 or M 300 and 2.5 measures of sand.

Fireclay sand and fireclay crushed stone are needed to prepare mixtures with increased heat resistance. Such solutions are used in laying the bottom of the firebox and the walls of the firebox. The mixtures include:

- cement brands M 300 or M 400 — 1 measure;

- fine-grained sand and broken brick (fireclay rubble) - 2 measures;

- 0.3-0.5 measures fireclay or regular sand.

Stove makers use tap, melt, river or spring water. It should be "soft", a high content of mineral salts will lead to the fact that on the walls and chimney after the masonry has dried out, white marks and streaksThey also appear on the chimney after heavy rains.

The procedure for preparing cement-sand mortar:

- Into the container pour in the calculated amount of cement and sand.

- Ingredients mix with a spatula.

- Water is poured into the mixture, stir the mass in a concrete mixer or a construction mixer. Manual mixing with a spatula is allowed if the volume of the solution is small.

When choosing materials, you should focus on their quality. Compacted, lumpy, long-stored cement, unsifted and unwashed sand are not suitable for mixing.

What to do if the mixture has dried out

Cement paste after hardening by strength resembles natural stone. His cannot be dissolved with water or chemicalsWhen the mixture hardens, water enters the structure of the cement and gives it high strength.

If the solidified mass is broken up and ground, the result is a powder similar to the original cement from the factory packaging. "Reconstituted" material loses its qualities And becomes unusable for such important works as laying the foundation and chimney of the stove.

For complete restoration of cement with removal of bound water special factory equipment is neededThis process occurs at high temperatures, and it is impossible to carry it out independently at home.

Important! At air temperature 20 degrees the cement begins to "set" after 2 hours. At temperature 30 degrees the mass hardens faster (for 1-1.5 hours).

The mixture is too thin or too thick.

If the cement-sand mixture is too thick, add it to the container add water in small portions And stir the contentsIf there is a lot of water in the mixture, it make it thicker, adding calculated portions of dry cement and sand (for example, 1 measure of cement and 3 measures of sand are added at the same time).

Reference. The quality of the cement-sand paste is checked with a trowel. A properly made solution does not flow or fall in pieces from its working surface when tilted in 45 degrees.

Building compounds made using cement and water, are not subject to storageIntensive stirring helps to slow down the hardening process.

Lime mortar with your own hands

Paste-like lime-based materials can be stored in a hermetically sealed container or bag. for a long timeTo prepare it, you need a container and a wooden stirrer.

What materials are needed for preparation?

For a quality lime mortar you need: slaked lime, washed sand and clean water. The components are mixed in such proportion:

- 3 measures fine-grained sand (with particle size 1.5 mm and less);

- 1 measure slaked lime paste.

Slaked lime (in sealed bags) sold in hardware stores. They also offer lump unslaked lime, which can be prepare it yourself.

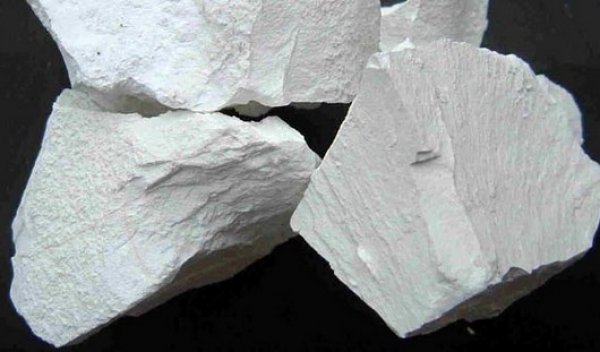

Photo 2. Quicklime in the form of lumps. You can slake it yourself using a large container and cold water.

A large tank or trough is needed for the work. Lime is also slaked in a specially dug shallow pit. The quenching is carried out as follows:

- On the bottom of the container in an even layer pour limeThe amount of raw material does not have to be large, it is enough to fill the vessel. by a third of the volume.

- Into the vessel pour cold water (1 measure of water to 2 measures of lump quicklime). A violent reaction begins immediately, resembling boiling. If the container is not closed, the lime splashes onto the ground. The wall of the vessel heats up strongly.

- If there is not enough water, it you can add more, while the boiling process is going on and steam is being released. You should not pour a lot of water, the purpose of quenching in this case is to obtain a paste-like material.

- Lime stir with a rakeso that all pieces of raw material react with water.

- After the active reaction has ceased, the vessel leave for 1-1.5 days.

The optimum density of slaked lime for stove masonry should be not less than 1400 kilograms per cubic meter. The consistency of slaked lime is of such density looks like liquid dough.

Attention! Quicklime reacts with moisture on the skin and causes deep chemical burns. Slaked lime also affects the body. All work with these substances is carried out in closed clothing, shoes and gloves.

How to cook

For mixing, measure out the required amount of sand and slaked lime in advance. The container for the mixture can be metal (without traces of rust), plastic or enamel. The procedure for preparing the solution includes the following steps:

- Paste-like slaked lime rubbed through a metal sieveSmall stones, plant remains and roots, and debris are removed from it.

- Wiped material transfer into a container.

- Sand is poured on top.

- If necessary add water.

- Solution Ingredients mix thoroughly with a spatula or a construction mixer.

- Check the thickness of the resulting paste. The solution is tested for viscosity using a construction trowel in the same way as cement and clay solutions.

Reference. The lime-sand mortar is ready for use immediately after preparation.

What to do if it dries out

Dried lime mortar cannot be restored. After being crushed into pieces with a hammer and removed from the tank, it can be thrown away or used for other purposes. After being crushed in a crusher, the resulting powder Suitable for improving the composition of garden soil.

Too thick or too runny

Thick lime based solution dilute by adding water.

Add water in small portions and thoroughly mix the paste with a mixer, periodically checking the thickness of the “dough”.

If the solution turns out to be liquid, it is thickened.

For this purpose, in a container add lime and sand, measuring them out in the required proportions, and mix thoroughly.

Lime-cement mortars

Solutions containing lime, sand and cement, are considered complex. Cement gives the lime-sand paste additional strength and moisture resistance. Percentage composition of the mixture depends on the type of cement.

Photo 3. Lime-cement mortar package weighing 30 kg. Manufacturer "Quick-mix".

Refractory additives in mixtures for stove masonry

To increase heat resistance, moisture resistance and solidity, mechanical and chemical additives are introduced into the solutions. Salt added to formulations that will not be used outdoors. This substance prevents the mortar from freezing quickly if the masonry is carried out at low temperatures. Lime with salt crumbles less and does not crumble.

When laying the lower part of the chimney and the stove itself, stove makers introduce lime and clay solutions heat resistant glue. It contains substances that increase the mixture's resistance to high temperatures and its overall viscosity. The glue is added according to the instructions on the package.

Photo 4. Two packs of heat-resistant glue, 25 and 5 kg. Manufacturer "Plitonit".

To increase heat resistance, the ingredients of the mixture are added asbestos fiberIf the furnace foundation is laid at sub-zero temperatures, factory-made anti-freeze agents are added to the cement.

Not all stove makers use additives. If the solution is prepared from purified, carefully prepared materials, with precise proportions, it will be of high quality, will not crack or crumble.

Manufacturers add to factory mixes for building fireplaces and stoves plasticizers. This is a large group of substances that increase the heat resistance and monolithicity of masonry. Mixtures for stove masonry, which include plasticizers, are considered improved.

Useful video

Watch the video, which explains how to mix cement mortar correctly: what to use for this, the order of actions, proportions.

Comments