How not to get confused when studying the assortment: choosing taps for heating radiators

In most apartments and private houses the source of heat is a water heating radiator. The cost of heating in this case is up to 80% of the home's energy consumption.

To increase the efficiency of the system, shut-off valves are used to regulate the flow of hot water through the radiator in accordance with the specified conditions.

The efficiency of regulators depends on the right choice these products.

Content

Objectives and tasks of installation of shut-off and control valves

In the simplest heating system, you can do without any type of taps at all.

But the requirements for the convenience of setting up and servicing heating batteries stand out four main use cases these products.

Heating radiator maintenance

Basic ball valves installed on the supply and return pipelines will help to eliminate a leak or replace a heating device without draining the coolant from the system. Operating position of the device - open or closed, the consumption of hot water in the open position is maximum, in the closed position it is absent.

Manual control of coolant flow

Smooth regulation of the amount of liquid in the radiator helps cone tap. The cone-shaped stem in its design gives the user the ability to approximately adjust a comfortable microclimate. In extreme positions, the valve completely blocks or opens the flow of water.

Removing air from the system

The air lock that forms in the upper part of the radiators when the water is turned on does not allow the working surface of the heating device to be fully used.

A specialized device helps remove this air. Mayevsky crane.

In working condition its valve is always closed, opens only when setting up the system.

Automatic flow control

Precise adjustment of the microclimate is possible Regulating valve with thermostatic head. The liquid or gas bellows in its composition reacts to changes in ambient temperature and automatically controls the flow of the coolant.

Technical parameters

To the types of construction These include ball valves, cone valves, thermostatic valves, and Mayevsky valves.

Ball

The basis of the design is a movable spherical shutter — a ball with a drilled hole for water to pass through. The ball is connected with a handle, which is what sets it in rotation. The body of the tap is made of steel, bronze and brass, as well as polypropylene.

Photo 1. Full bore ball valve with a polypropylene body, suitable for pipes made of the same material.

Ball valves are divided into full bore and standard bore. Full bore pipes are most widely used in heating systems. Due to the absence of narrowing of the pipe diameter, they make it possible to use the heat output of radiators to the maximum.

A simple algorithm for choosing a ball valve: if the system pipeline material is polypropylene, then the optimal solution would be to install a polypropylene device. In other cases, it is necessary to install equipment with a metal body. It is recommended to purchase products well-known manufacturers.

Attention! The ball valve can be opened only halfway, but it cannot be used in this mode - it is too wear of parts increases.

Conical

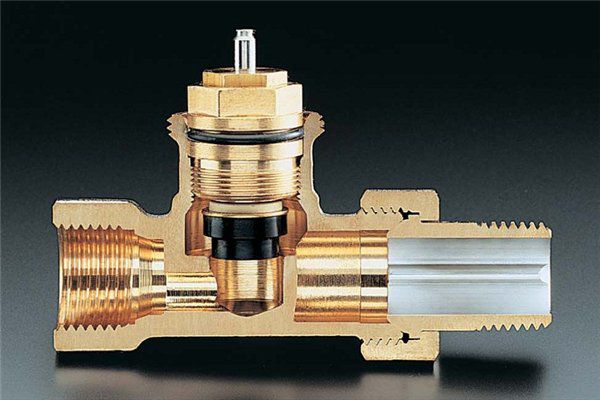

In a cone valve, the control valve has the shape truncated cone. When the handle is rotated, the cone moves along the thread, smoothly adjusting the cross-section of the lumen. The most widespread are brass and bronze bodies, polypropylene models are only gaining popularity.

Photo 2. Cone tap in section, made of brass and bronze, adjusts the temperature only approximately.

The design of the cone valve significantly reduces the internal diameter of the pipeline; in a system with such additional resistance, the parameters of the coolant must be strictly observed. Additionally, it will be necessary to carry out regular cleaning of the tap, often by removing it from the pipeline.

A cone valve will only help you set the room temperature approximately.

Cone valves are selected in the same way as ball valves: based on the pipeline material. Reliability Metal reinforcement is higher than plastic, but the latter is somewhat cheaper.

Crane "Maevsky"

This type of air bleed equipment is a metal needle type shut-off valve. The valve stem is moved by rotating the square screw with a screwdriver or a special key. The water coming in with the air must be collected in a container.

Photo 3. Mayevsky tap on a heating radiator, turns by rotating the screw with a screwdriver or a special key.

If the radiator is not equipped with a Mayevsky tap at the factory, then when purchasing, pay attention to connection size - it must match the size of the pipeline.

Important! The capacity of the tap is very small, do not use it to remove large volumes of air, for example, from the hydraulic accumulator.

Thermoregulating

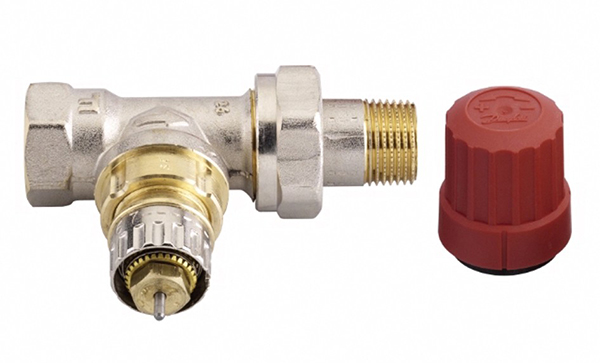

The most complex design has a pipeline valve with a thermostatic head. The push rod is controlled by a special container (bellows) filled with liquid or gas. Using the properties of changing the volume of media with increasing temperature, the bellows, acting on the working cone, regulates the flow of liquid.

The initial position of the bellows is set by the user using a digital controller or by turning a mechanical handle. In complex automatic control systems, the position of the rod is set specialized computer, which processes information from external sensors and controls the electric drive.

Photo 4. Thermostatic radiator valve with a special bellows filled with gas or liquid.

To navigate the fittings for domestic use, it is enough to pay attention to the markings:

- Products with the letter G are used in one-pipe systems;

- with the letter N - in two-pipe;

- the direction of water flow in the working position is indicated by an arrow on the tap body.

Reference! To reduce the influence of the radiator on the thermostat head, it is positioned at an angle 90 degrees to the battery plane.

General installation rules

The heating system circulates hot water under high pressure! Observe safety precautions when working with pipeline elements, if possible involve specialized organization.

The rules for installing taps in a metal pipeline are slightly different differ from the general order of plumbing works. Before starting production, it is necessary to drain the coolant from the system.

In apartment buildings, this procedure is performed only by the service organization.

Think about the placement of all elements, the handles should rotate freely along the entire length of the working stroke, the taps themselves should be easily accessible, It is advisable to organize free space around them for maintenance.

Apply sealant to the thread. Screw the tap into the pipeline, install the battery.

Do it high pressure system test. In apartment buildings, it is carried out by the service organization. Check the connection points for leaks, tighten the threaded connections if necessary.

When using polypropylene pipes It is better to entrust the installation of shut-off valves to specialists who have the appropriate welding tools.

Typical placements

Depending on the heating system design, standard locations for shut-off and control valves are used.

The type of system is determined by the external features of the pipeline layout; a distinction is made between one-pipe and two-pipe heating system.

As the name suggests, in a single-pipe system, the supply and removal of the coolant is carried out through one pipe. This scheme is mainly found in central heating systems in Soviet-built buildings, as well as in private homes with autonomous heating.

In apartment buildings with individual roof boiler room A two-pipe heating system is used, in which the supply and return pipes are separated. This system is ideal for installing thermostatic valves, allowing for maximum use of their capabilities.

In one-pipe and two-pipe systems the connection of the fittings to the radiator is carried out from the side, making optimal use of the radiator's heat output. Due to design restrictions on the placement of the pipeline, other connection methods are possible, which reduce the radiator's efficiency.

With the development of the design of heating devices, it became possible to perform connecting taps to the battery from below, using a special pipe assembly. The thermostatic head in this version is located at the level of the upper radiator inlet.

And also received development diagonal connection control valves. This method is used to connect batteries with a large number of sections, which ensures uniform heating.

Useful video

A video review in which a specialist talks about the advantages and disadvantages of shut-off and control products.

Comfortable warmth

As in any field of human activity, the design of radiator taps is constantly being improved. To get the most out of your investment, it is enough arm yourself with theory and then carefully study the range fittings offered by manufacturers.

These simple components will give an excellent result, and your choice will please you. balanced cost with expected efficiency and a solid service life.