Keep all the heat to yourself! Heating pipes: which are better and more reliable?

In the heating system pipes perform the task of transporting the coolant from the distribution unit or boiler to heating devices (radiators).

For the efficient operation of the heating system, it is necessary to select the correct pipes based on their installation features, material, and cost of the products.

Content

Pipes or radiators: what to make heating from

Only pipes for heating the room (without radiators) not enough for the following reasons:

- radiators provide heating in places where cold air enters (under window openings);

- the radiators look aesthetically pleasing, fitting organically into the design of the room;

- pipes are not capable of heating by thermal convection;

- the cost of installation (welding) of heating systems made of pipes is comparable to or exceeds the price of a system of similar thermal power made of panel or cast iron radiators.

In residential and public spaces, it is better to install radiators that perform room heating function, and the pipes are sold transport function — supply the coolant to the radiator and remove it back into the system.

Register heating system without radiators, it is used in large industrial premises where superheated steam is used as a heat carrier.

What pipes are best to use for a heating system

When choosing pipes for a heating system The following parameters need to be taken into account:

- Compliance of the material with the temperature and pressure of the coolant.

- Convenience of installation and assembly.

- Cost of materials and work.

- Appearance (aesthetics).

- Service life.

Heating pipes are classified according to the materials they are made of. Materials are divided into two large groups: metal and plastic (polymer).

Metal:

- made of steel;

- made of galvanized steel;

- made of stainless steel;

- made of copper.

Plastic:

- made of polypropylene;

- made of cross-linked polyethylene;

- made of metal-plastic.

Steel

The pipe material is black steel. They are measured sections of solid-rolled or electric-welded rolled pipes. Pipes with a wall thickness of 2.8 -3.2 mm.

Photo 1. Heating steel pipe connected to the radiator. The product is made of black steel.

Pros:

- Mechanical strength, resistance to temperatures and pressures that significantly exceed the parameters of most domestic central and individual heating systems.

- The thermal expansion of steel pipes is minimal compared to polymer pipes and amounts to 6 mm per 10 meters length (when heated from 20°C to 90°C).

- Corrosion resistance. In closed heating circuits, there is virtually no oxygen, which causes oxidation and destruction of metal.

- Low cost compared to other materials.

Cons:

- It is difficult to hide a steel pipe in a plaster groove, therefore, in plastered rooms they are laid openly. They need decorative painting.

- The labor intensity of installing a steel system. Welding (electric or gas) is required, labor-intensive metalworking operations are required to cut threads and assemble connections. The installation process is dirty and is performed before finishing work.

- When purchasing a pipe, you need to check it for compliance with GOST requirements, due to the high risk of purchasing a low-quality old pipe or Chinese counterfeit. Low-quality material may have a discrepancy in steel composition or wall thickness, which affects durability.

- Central heating systems can become clogged with deposits, which narrow the useful clearance, reducing the flow and heat transfer of the coolant.

Connections

Steel pipelines are connected in two ways:

- on threaded connections;

- by welding

Threaded connections of steel pipes are made using cast iron fittings (tees, barrels, bends, corners and others), which have a cylindrical thread inside.

The steel blank is threaded using a ratchet die and a thread-cutting die. The parts are connected using sealing materials. Flax with paste and anaerobic sealants are most often used.

Welded joints of steel blanks are performed using gas (acetylene-oxygen) or electric welding.

Term services

The standard service life of black steel pipes before major repairs (before replacement) is 25-30 years old depending on the type of premises and the purpose of the pipeline. The actual service life of a high-quality steel pipe made according to GOST, is 40-50 years old.

Galvanized steel

They are made of steel pipes, coated with a layer of zinc on the outside and inside electrochemical method (galvanic or diffusion).

Galvanizing performs a protective function, prevents air from penetrating to the base metal, protecting it from corrosion.

Pros:

- Mechanical strength.

- Anti-corrosion resistance at coolant temperature up to 65°C (on cold water supply).

Cons:

- Labor intensity of installation processes.

- When welding, respiratory protection from toxic zinc fumes is required.

- At the coolant temperature over 65°C the zinc coating is destroyed, which leads to corrosion, clogging of the coolant and malfunctions of the boiler equipment.

Attention! In heating systems with temperature over 65°C It is not recommended to use galvanized steel.

Connections

Galvanized pipes, like steel ones, are connected in two ways:

- on threaded connections;

- by welding.

When performing welding and application threads zinc coating is damaged, which reduces the protective properties of galvanizing.

Term services

The standard service life of galvanized steel in cold water supply is 15-20 years before major repairs.

Stainless steel

Produced by foreign manufacturers such as Viega, Sanha, Geberit. Each manufacturer offers its own system of stainless steel heating pipes with its own pipes, press fittings and installation instructions. The wall thickness is from 0.8 to 1.0 mm.

Pros:

- Mechanical strength.

- Anti-corrosion resistance.

- Smooth inner surface that does not become clogged with deposits.

- Aesthetic appearance.

- Reliability of press connections at operating temperatures and pressures.

- Easy to install with a crimping tool.

- Long service life.

Cons:

- High cost of material (2 times higher than copper), press fittings, tools.

- If water treatment is poor (the presence of oxygen in the coolant), it can form a galvanic pair with copper, which leads to electrochemical corrosion.

Connections

For connections of stainless steel pipeline parts Press fittings are used.

Mechanical compression of the press fitting material around a stainless steel pipe with a special tool and a system of special seals made of synthetic heat-resistant rubber EPDM as part of the fitting, it ensures mechanical strength of the connection, tightness, resistance to mechanical impacts and temperature.

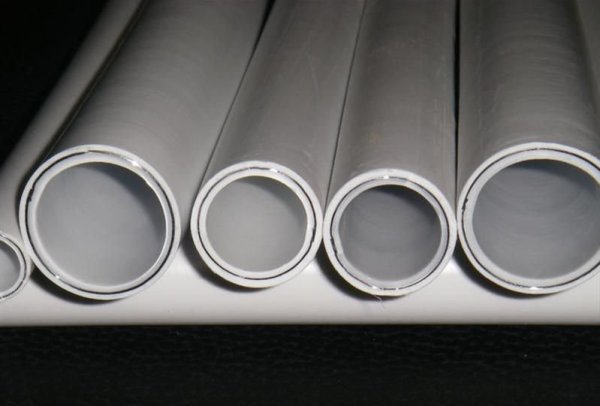

Photo 2. Smooth stainless steel pipes. Products made of this material are quite often used in heating systems.

Sanha declares for its system NiroSan stainless steel working pressure PN40 for pipe diameter 15-22 mm and operating temperature up to 120°С (short term) up to 150°C).

Term services

Manufacturers declare the service life of stainless steel pipelines 40-50 years old.

Copper

Copper pipes for heating are produced in the form of rods (rigid pipes) and coils (semi-soft pipes with a wall thickness from 0.7 to 1.2 mm. The most common method of connection is soldering with special solders. There is also a method developed by the company Viega copper pipe connection system with press fittings Profipress-s and a system of connections using compression fittings with a union nut.

Pros:

- The physical properties of the material are comparable to stainless steel, but the cost of copper pipe 2 times less.

- Possibility of installing soldered joints at home, without using expensive pressing tools.

Cons:

- It is necessary to take into account the possible electrochemical reaction with other materials in the system (aluminum, galvanized steel, stainless steel).

- High thermal conductivity.

- Low abrasive resistance.

For hidden installation in a screed or wall, copper the pipe is installed in a heat insulator made of foamed polyethyleneto reduce heat loss and prevent abrasive effects of screed or plaster particles.

Connections

- Press fittings — the operating principle is similar to stainless steel press fitting systems. The system manufacturer (Viega) declares the working pressure 16 bar at temperatures up to 140°C.

- Compression fittings — the seal of the connection in the fitting is ensured by pressing with a brass ring when screwing the union nut. This connection is detachable and should be used in open systems with the possibility of quick access.

- Soldering with special solders using flux. The equipment required is a propane or acetylene torch.

Term services

Service life of copper pipes not less than 50 years.

Polypropylene

For radiator heating it is recommended to use new generation polypropylene pipes Ecoplastic STABI PLUS made of polypropylene PP-RCT, reinforced with a continuous layer of aluminum in the surface layer.

Pros:

- high throughput;

- a continuous layer of aluminum acts as an oxygen barrier;

- high resistance to temperature and pressure - 8 bar at 90ºС;

- minimum thermal elongation - with increasing temperature from 20 to 60 ºС the pipe is extended by 2 mm/1 m.

Cons:

- If the temperature regime is violated (overheating during welding), the throughput diameter in the fitting decreases.

Connections

The connection of the pipe with fittings is performed by diffusion welding method, in which a homogeneous structure is formed at the junction, identical to the rest of the material.

Before welding need to do some cleaning - remove the outer layer of aluminum.

Term services

In the 5th class of operation (radiator heating in residential premises with maximum coolant temperature 90ºС) the manufacturer guarantees the service life 50 years old.

Sewn polyethylene

Cross-linked polyethylene (PEX) is polyethylene whose molecular units are linked (cross-linked) into a three-dimensional structure to increase temperature resistance. PEX pipes are used usually for installing heated floors in private homes.

Photo 3. Laying a heated floor using tubular products made of cross-linked polyethylene. The material is more often used in private homes.

Pros:

- high temperature resistance - up to 110ºС and pressure 10 bar (REHAU);

- resistance to deformation under high pressure;

- maximum flexibility among all types of polymer pipes;

- no deposits on the inner surface.

Cons:

- unsuitability for central heating systems;

- PEX pipes do not have the necessary aesthetics when laid open due to their curvature;

- high cost of installation tools.

Connections

PEX connections - pipes with fittings are performed using sliding sleeves. First, the end of the workpiece is expanded with a special expander and put on the fitting. Due to molecular memory, the material tends to return to its original position and tightly compresses the fitting. A special tool the sleeve is moved to the place of connection to completely fix the end of the pipe on the fitting.

Term services

According to GOST R 52134-2003 at coolant temperature 90ºС and pressure 9.1 bar the service life of a PEX pipe will be 10 years.

Metal-plastic

The metal-plastic pipe consists of an outer and inner layer of PEX polyethylene, which are glued through a layer of aluminum 0.4 mm thick.

Photo 4. Heating pipes made of metal-plastic. Consists of three layers: outer and inner - made of polyethylene, the middle - made of aluminum.

Pros:

- high temperature resistance - up to 110ºС and pressure 10 bar

- higher strength than PEX pipes;

- coefficient of linear expansion 7 times less, than PEX pipes;

- oxygen impermeability;

- easy installation on press fittings.

Cons:

- strength, operating temperature range is smaller than that of steel and copper;

- aging of the material under the influence of ultraviolet radiation (concealed installation is recommended);

- pressure surges reduce service life;

- cost of crimping tool for press fittings.

Connections

For heating it is recommended to use connections based on press fittings.

The workpiece is calibrated, placed on the fitting, and a metal sleeve is pressed around it, ensuring mechanical strength.

Two gaskets made of heat-resistant rubber provide stability connections to temperature fluctuations and mechanical impacts.

Choice diameter

Pipeline diameter is determined by the calculation of the heating system, based on the area of the room, the power of the radiators, the speed of the coolant and other factors.

Selection material under the screed gender

For hidden installation in floor screeds (for installing heated floors) It is recommended to use metal-plastic or cross-linked polyethylene. These materials are strong and flexible enough to allow for easy installation.

Useful video

Watch the video, which tells you what to look for when choosing pipes for heating your home.

The best products that can be installed in heating systems

For heating, it is recommended to choose materials which correspond to the system parameters. For the central For heating, metal systems are optimal, as they are the most reliable and durable. For autonomous heating of private houses, it is preferable to choose a system made of polymeric materials, as the most convenient to install. It remains only to choose the appropriate one.

Comments