How to decide on the choice and installation of heating for a private house with your own hands: diagrams of different types of connections

This is a very important question. If you make a mistake in choosing a heating system it will be cold in the rooms, or expenses for heating will prove to be completely unbearable.

Do-it-yourself heating connection diagrams for a private home

Exists several types heating systems for a private home that you can make yourself.

One-pipe systems

The key element is boiler. In it, the coolant heats up, passes through the heating system and returns back to the boiler, where the water heats up again.

The cold water intake pipe is the second part of the system. The entire system has a circular, closed nature of a continuous cycle.

One-pipe systems are:

- Closed — does not communicate with the surrounding air, and if there is excess pressure inside, the excess air is removed manually. The volume of liquid in the system is constant.

- Open — have a non-hermetic expansion tank into which excess air is displaced. The pipes running through the house are located above the heating devices (to displace air into the tank).

From the water heating boiler comes out one pipe and, sequentially running around all the radiators, returns back.

Pros:

- low cost;

- the flow of water is directed as desired;

- ease of installation;

- the system can be mounted under a wall or under the floor;

- use of any boiler (solid fuel, gas, electric);

- All elements of the system are connected to the distribution pipe.

Cons:

- High cost.

- The water temperature decreases from one battery to another., and if many radiators are connected, the last one is already cold. To heat all the rooms, it is necessary to significantly increase the heating temperature, which entails additional costs.

- The coolant flow requires high pressure, for which an additional pump is cut in.

- High pressure in the system leads to wear (a large number of leaks occur).

- The system that has not been used for a long time, starts with difficulty.

- Without proper slope installation, air pockets may form in the chain., which makes heat transfer difficult.

- It is not possible to repair a single link without shutting down the entire system.

Horizontal

The operating principle is based on the circulation of the coolant in a closed horizontal circuit, which enters and exits from the same boiler.

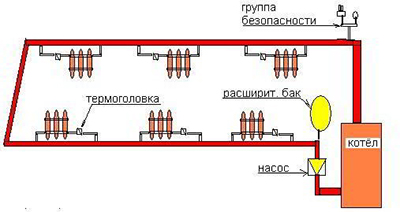

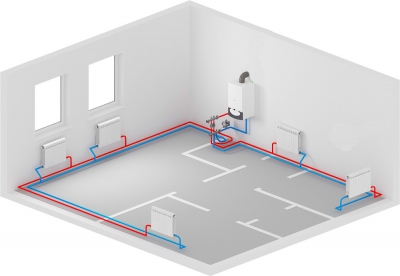

Photo 1. Horizontal single-pipe heating system with a main pipe from which the distribution lines go to the radiators.

The main pipe is laid horizontally from the heating boiler (on the floor or under the floor), from which branches are made to the radiators. If the house is two-story, then on the first floor a riser is cut into the main pipe to supply water to the second floor.

Attention! The main pipe is being laid at a slight angle (with natural circulation of the coolant), while the batteries should be installed at the same level.

If the structure is mounted in the floor, the pipes are insulated to prevent excess heat loss.

Pros:

- ease of installation;

- cheapness;

- if the system is equipped with bypasses, then the difference in temperature is small;

- Removing one battery does not require disconnecting the entire system;

- the circulation of the coolant will be quite fast.

Cons:

- temperature control on individual radiators is not possible;

- when repairing one link, the entire system must be stopped;

- the difference in temperature between the first and last radiator is very large.

The connection can be:

- Flowing (high heat loss, not recommended for small spaces).

- With bypasses (the bypass diameter should be smaller than the main pipe. Some of the water goes to the radiator, the rest moves further through the system).

- Lower (possible with forced passage of liquid).

- Diagonal (better for heat dissipation).

Important! If the system is mounted for a two-story house, then the equipment must include a pump for forced circulation of liquid.

Only metal pipes can be attached to the boiler.

Vertical

All batteries in parallel are connected to vertical risers. It is advisable to install this system in buildings with more than two floors. The heated coolant goes from top to bottom.

The heated coolant supplied from the boiler goes to the tank at the top and from there along the conducting line it is distributed to the radiators. The cooled liquid returns to the boiler.

Pros:

- ease of installation;

- uniformity of heat distribution;

- when repairing one floor, it is not necessary to disconnect the other;

- good natural current.

Cons:

- high consumption of pipes;

- Heating large rooms is difficult.

Installation nuances:

- The presence of an expansion tank is a must here. Installed at the peak point (attic).

- It is advisable to install one Mayevsky crane per floor.

- The main pipe is laid with a slight slope.

Only metal pipes can be attached to the boiler.

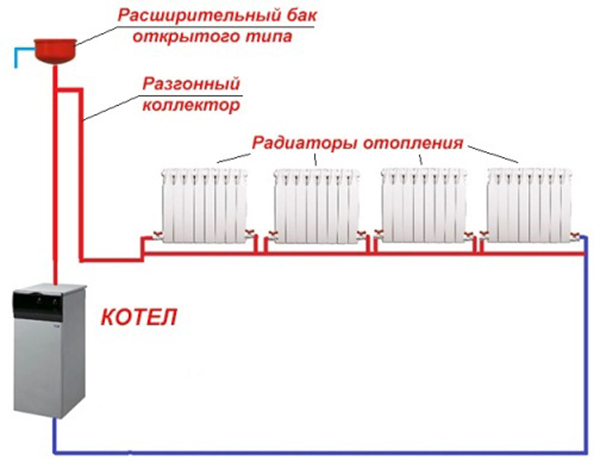

Project of the Leningradka scheme

The heated coolant leaves the heating boiler, passes through all connected heating devices in sequence and returns back.

"Leningradka" can be:

- vertical;

- horizontal;

- with top or bottom wiring.

The main pipeline is being laid along the outer walls of the building, encircling it along the perimeter. All heating devices, including heated floors, are connected to this pipe. The system is allowed insertion of modern elements (pump, thermostatic valves, bypasses, etc.).

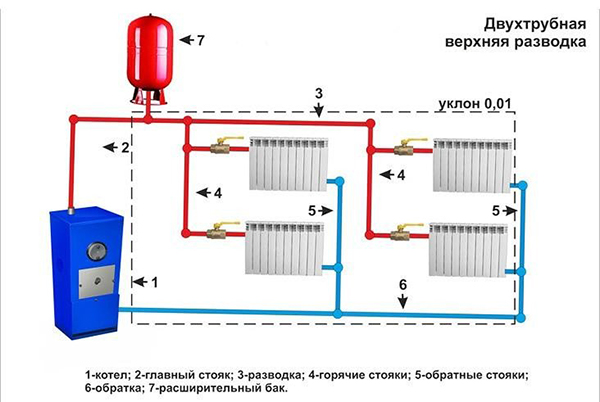

Photo 2. Diagram of the Leningradka heating system with a circulation pump, four radiators and an expansion tank.

Pros:

- possibility of connecting several heating boilers;

- low cost;

- low pipe consumption.

Cons:

- use of large diameter pipesso that the entire system works efficiently;

- air locks often form in the system;

- to the system You can connect heated floors or a heated towel rail, but there won’t be enough power for full-fledged operation.

When assembling the system, the following points must be taken into account:

- If the main pipe is laid below floor level, then Additionally, it is necessary to use thermal insulation to avoid overheating of the floor.

- The main pipe is extended at a slight angle.

- The expansion tank must be installed close to the boiler.

- The pump can only be installed after the expansion tank. in the direction of the coolant flow.

- Installation heating is carried out before any finishing work begins.

- Radiators are located on one level only.

Important! Due to excessive air in the chain, use Mayevsky cranes Necessarily.

During installation, it is necessary to avoid sharp changes in height, since in this case traffic jams are guaranteed.

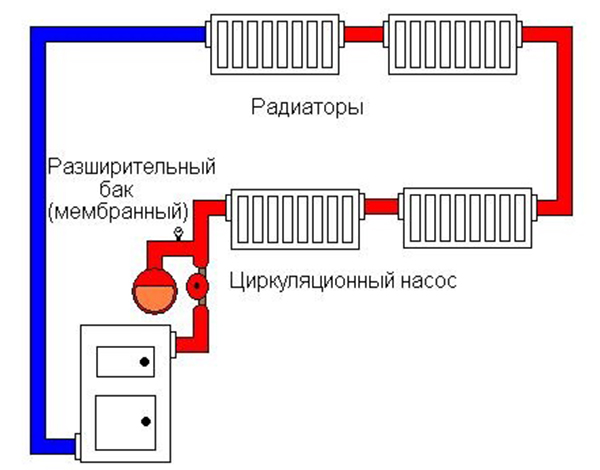

Two-pipe with bottom distribution

The main difference between this system and a single-pipe system is the number of pipes: hot water is supplied through one, and cold water is discharged through the other.

Both pipes (both supply and return) are located below the radiators. The pipe with the hot coolant is laid above the return pipe. The liquid moves from the bottom up in the system.

Exists two ways to connect batteries:

- ray — each radiator is connected to the main pipe by separate branches;

- consistent.

The system can be mounted with:

- along the same path (the liquid in both pipes moves in the same direction);

- dead end (the coolant moves in different directions);

- one;

- several.

Pros:

- Autonomy of floor heating;

- possibility of operation until the construction of the house is terminated;

- low heat loss due to installation features;

- The central block can be placed in the basement.

Cons:

- airiness systems - air must be released daily;

- when installing an overhead line system becomes unnecessarily bulky;

- high consumption of materials (especially for radial connection);

- adjustments should be made before the onset of cold weather;

- low pressure in the supply coolant.

When laying the chain, the following points must be taken into account:

- Radiators are additionally equipped with Mayevsky taps to remove air from the system (air vents can be installed).

- If the system is installed in a multi-storey building, then laying an overhead line, through which excess air is discharged into the expansion tank.

- If the main pipe is located near the entrance door during installation, it can be divided into 2 elbows.

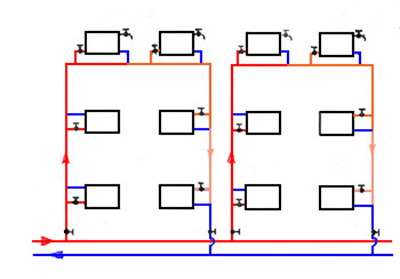

Two-pipe with top distribution

This system is good for multi-story buildings. The heated coolant under pressure goes from the bottom up into the tank, and from there - through the supply pipe to the radiators. The system with the top supply is always vertical, the heating radiators are mounted parallel to the vertical risers.

The supply pipe runs through the attic or technical floor, and the return pipe in the basement or below ground level on the first floor.

Photo 3. The diagram of a two-pipe heating system with top wiring is suitable for private houses with two or more floors.

Pros:

- ease of installation;

- low heat loss;

- there is no airiness;

- excellent natural circulation.

Cons:

- it will not be possible to install a large number of radiators;

- high consumption of components;

- does not heat a large area.

The chain is mounted taking into account three points:

- mandatory installation of an expansion tank at the highest point of the supply pipe;

- if the coolant flow is natural, then when laying both pipes, a slight slope is taken into account;

- The supply pipe goes to the batteries through the expansion tank.

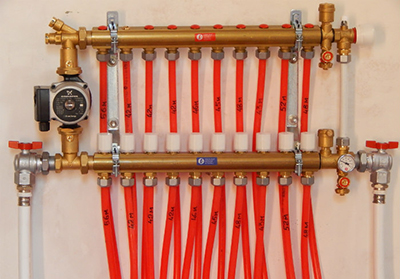

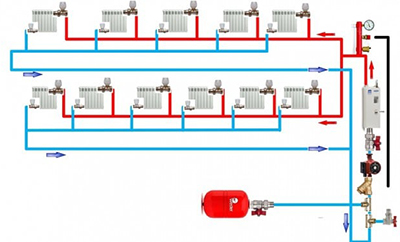

Beam system with collectors

A collector is connected to the heating boiler - single heating unit, from which each radiator in the room has its own branch. The collector can be:

- simple;

- improved (with thermostatic automation).

This option is suitable for a two-story house. From the collector goes from two to twelve knots — depending on the number of radiators in the house. If necessary, the number of branches increases.

To the collector comb you can connect a pump — for forced circulation of liquid. And hide the structure itself in a closet so as not to spoil the aesthetics of the house.

Pros:

- durability;

- convenience during repairs (no need to disconnect the entire circuit);

- temperature control;

- uniform temperature in all rooms.

Cons:

- price.

Reference! To at least somehow reduce the cost of pipes, it is better to install a manifold cabinet in the central part of the house.

Installation nuances:

- Typically, metal-plastic pipes are used in this system. When installing in the floor, it is recommended to wrap each pipe in insulation to avoid injury from concrete during expansion.

- Recommended diameter: 16 mm.

- Pipes cannot be run through doorways. - otherwise the pipes may be damaged when drilling.

- When laying through walls, it is recommended to lay in cartridges.

With forced circulation

The built-in pump ensures rapid circulation of liquid in the system, which reduces heat loss along the flow path.

Increased speed prevents hot and cold water from mixing - the temperature in all rooms is uniform.

By adjusting the speed of the coolant flow, the temperature in the room is controlled.

According to the design, a pump for accelerating the coolant is built into the forced circulation system.

Pros:

- comfortable operation;

- the ability to choose the mounting scheme (collector, single-pipe, double-pipe);

- heating regulation;

- increasing the service life of components;

- installation of pipes of smaller cross-section.

Cons:

- pumping system increases initial installation costs;

- noise from the operating pump;

- additional electricity costs.

Installation nuances:

Place of installation of the pump group depends on the method of piping. Due to the artificial pressure inside the system, the slope is not installed.

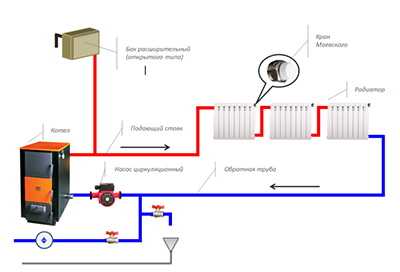

With natural circulation

The liquid in the system, heating up, rises up and goes into the radiators, where the coolant cools down. The cold liquid goes down. The pressure depends from the temperature difference. The cycle is closed.

- The boiler is installed below the level of the radiators.

- The branch pipes are smaller in diameter than the main pipe.

- The correct connection would be diagonal., in which hot water enters the radiator from above.

- To improve fluid circulation a slight slope is provided.

Install an expansion tank: if there is excess pressure, some of the liquid will flow into it, and if it drops, it will return back to the system.

Pros:

- low cost;

- possibility of installation of one- or two-pipe systems to choose from;

- light repair;

- does not clutter up space;

- reliability;

- long service life.

Cons:

Only available in single-pipe natural circulation systems:

- Uneven heat distribution: The rooms located closer to the boiler are hot, while those located further away are cold.

- Additional costs: To increase the temperature in cool rooms, batteries are added or powerful radiators are installed.

- Increased fuel consumption (compared to pump type).

Installation nuances:

- The circuit is equipped with overheating protection to prevent air from entering.

- Each radiator is equipped with a bypass, a thermostat and a Mayevsky valve.

In natural circulation circuits, only water is used (antifreeze is not suitable due to its density).

Useful video

Watch a video review of a two-pipe heating system, connection options, pros and cons.

In conclusion

Despite its apparent simplicity, installation heating requires a lot more work: choose a suitable system and purchase materials, calculate the amount of fittings, footage, connect the components so that a geyser does not burst out of the wall in frost. Therefore It's better to entrust this work to professionals, and enjoy the warmth and comfort yourself.

I would like to point out separately that it is prohibited to use antifreeze in galvanized systems.