70 degrees of heat for health and relaxation: how to install a stove with a closed heater in a bathhouse

The traditional Russian bath has more than a thousand years of history, and the positive and healing effects of bath procedures are known to many people.

Distinctive features of the Russian bath – high humidity, large amount of hot steam. The air temperature in the steam room can reach 50-70 degrees with humidity up to 60 percent.

The sauna stoves themselves are significantly different from the usual devices used for heating a home.

Content

What kind of stove can be built for a bathhouse?

According to the type of device, there are two designs:

- With a closed heater — a traditional option that allows keep warm for a long time in a steam room. The stones are placed inside the stove on a grate, usually in several levels, and are heated by the flame and hot air. Stove it heats up within four hours, after which the high temperature in the room remains for up to two days.

Photo 1. Brick sauna stove with a closed heater. A structure of this size is enough to heat the entire room.

- With an open stove — the stones are poured from above and remain open. The device allows warm up quickly room, but such a stove cools down quickly.

The most common type of sauna stove is one with a closed heater. complex structure and large dimensions allow you to heat the room efficiently, and then maintain the heat level for a long time and ensure the formation of steam.

Types of stoves with closed heaters

The following materials are used to make furnaces:

- Brick — a traditional option that provides slow and even heating walls of the furnace, as well as long-term heat transfer. Devices made of this material have long service life, but their flaws - quite long and troublesome kindling, complex and expensive maintenance and construction.

- Metal — is most often used to create heating devices stainless steel or cast iron. The advantage of such devices will be fast heating premises, achieving high temperatures with lower air humidity, lack of devices - rapid coolingIt is better to use metal models in small spaces.

- Combined — most often this option is used in the case of installing a cast iron stove, which they cover it with a brick screen to protect against cracking in case of accidental cold water penetration. Brick cladding increases the duration of heat transfer.

Photo 2. An example of a combined design: a metal stove is lined with bricks on all sides for safety.

By fuel type Furnaces are divided into the following types:

- Wood burning devices. Allows you to achieve quality parameters by the degree of heating of the room, the amount of steam.

- Gas devices. Often differ compact size, are suitable for saunas where there is no need for a large amount of steam.

- Electrical models. Convenient but expensive option, compact and multifunctional, often installed in an apartment.

Size brick stoves with a closed stone chamber are quite large. This is due to the need to increase the duration of heat transfer. Metallic Models can be small but effective, especially with a two-chamber, long-burning design.

Choosing a stove: cast iron or brick?

When choosing a model of a device for a bathhouse, the following are important: factors:

- desired warm-up time baths, amount of steam, duration of procedures;

- thermal insulation premises, its area, layout;

- material manufacturing;

- type of fuel;

- price equipment and its maintenance.

Often the choice is made in favor of brick and cast iron devices. A cast iron sauna stove with a closed heater is highly reliable and has a long service life, and also has a high heat capacity. Unlike a brick stove, a cast iron device is easier to install, its efficiency is almost as good as the traditional version.

Features of designs with an internal heater

Metal stoves with closed stone chamber consist of a fuel chamber, where the firewood burns out, and located on top compartment for stones.

Air enters the fuel chamber through grate, there is a retractable one located at the bottom ash pan. It is installed above the heater. chimney to remove smoke and some hot air.

Special latch door the compartment with stones allows you to regulate the air temperature in the room and the amount of steam. The stoves are also equipped with water heating tank, which is located on the side.

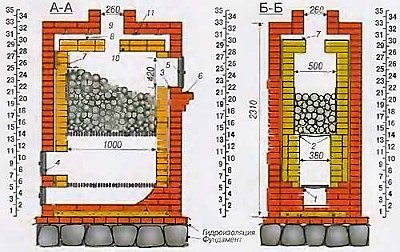

A brick oven with a closed heater resembles a metal device in design, but is usually more massive. For long-term heat transfer, brick devices are equipped with additional chimney channels. The heat from such a stove is retained for two days. The dimensions of the brick devices allow for convenient placement of a compartment with stones and a tank for heating water.

Building a sauna stove with your own hands

When choosing a design for a future furnace, the following are taken into account: conditions of a specific room - its area and quality of thermal insulation. Another significant factor that is paid attention to before construction is the availability of conditions for convenient installation of the chimney.

Important! If a steam room is created for a large family and friendly gatherings, it would be appropriate to establish large-sized brick stove. For a small steam room for 1-3 persons enough compact metal devices.

Materials

Construction begins with the choice of material. For a sauna stove you will need high-strength fireclay brick, characterized by high fire resistance. Suitable for laying external walls solid ceramic brick.

To do masonry mortar, mix clay with sand or use ready-made building mixtures based on heat-resistant cement.

Stones for the sauna stove must have high heat capacity and not crack when exposed to cold water. The shape of the stones must be round and even. Polished river cobblestones are good choices.

Tools

For the work you will need:

- capacity for mixing masonry mortar;

- shovel for mixing the solution;

- trowel for applying the mixture;

- hammer-pick for splitting bricks;

- hacksaw, grinder;

- rule to remove excess solution;

- plumb lines;

- building level;

- square.

Various metal elements: flaps, doors, and hinges They are purchased at construction stores.

Place for construction

The walls of the bathhouse are most often made of wood, so it is important to observe fire safety standards. The walls and ceiling where the stove is located are covered with non-combustible material, the device itself should be located at a distance 25-30 cm from the wall.

Photo 3. According to fire safety regulations, the wooden walls and floor around the metal stove were covered with brickwork.

If the stove is small, it is advisable to place it in the center of the room for better heat transfer.

Foundation

Depending on the size The area of the base of the future furnace is calculated, then the following work is carried out:

- A pit is being dug depth 50-60 cm, wet sand is placed on the bottom.

- A layer of crushed stone or broken bricks of thickness is poured not less than 10 cm.

- The formwork is being installed.

- Reinforced mesh is installed.

- Concrete mortar is poured.

- The foundation is being dried several days, then remove the formwork.

- A waterproofing layer made of roofing felt is laid over the foundation.

The foundation must get up above ground by 10-15 cm.

Laying order

In accordance with the pre-selected order and drawing, the masonry is carried out:

- It is laid out without a solution a layer of brick covering the entire bottom ovens.

- They are being laid out foundation walls, the evenness of the rows is checked with a level.

- It is being installed Ash pan with door and grate.

- It is being laid out combustion chamber made of fireclay bricks.

- It is being installed heater with door to release steam and boiler for heating water.

- It is being installed chimney and its thermal insulation.

Doing the masonry yourself can cause problems for an inexperienced craftsman, so recommended First, lay out the rows without mortar, and also prepare and cut the bricks.

Possible errors and difficulties

When building on your own, it is often allowed errors:

- usage unsuitable solution leads to cracking of seams during operation, to the danger of carbon monoxide poisoning;

- incorrect placement the device may make it difficult to use, since in the immediate vicinity of the oven the temperatures will exceed comfortable values;

- incorrect chimney design leads to contact between the pipe and the ceiling, which can cause a fire.

To avoid the above errors, it is recommended do not change the selected project, the order of the sauna stove.

Useful video

A video explaining some of the intricacies of building a sauna stove: where to place it, how to fold it, when and what to heat it with.

Correct operation

Increase service life simple operating rules will help you to operate the heating device:

- timely cleaning the ash pan and firebox from soot;

- periodic integrity check masonry and seams;

- regular inspection of stones, removal of cracked and split elements;

- installation steel fence over the heater will prevent soot from entering the room along with steam.

Comments

Pebbles can serve well for several years, but limestone no more than one season. But the steam from limestone is softer, enveloping.

And one more thing: it is best to locate the outlet of the bathroom stove not in the steam room or even in the washroom, but in the vestibule or in the changing room.