Trust but verify: heat meters for heating in an apartment building, the operating principle of the devices

Heat meter is multifunctional microprocessor a device programmed to calculate the amount of heat.

According to energy saving standards, such devices should be not only at central thermal power plants, but also in every home with central heating.

Content

- What is the purpose of a heat meter in an apartment building and how does it work?

- Types of heat meters based on their operating principle

- Accounting for the required amount of heat in an apartment

- Basic requirements for apartment appliances

- Useful video

- What to look for when choosing a heat meter for heating?

- Comments (1 opinion)

What is the purpose of a heat meter in an apartment building and how does it work?

To control the quality of heating services heat meters are used. If the radiators were not hot enough, then you will not have to pay the full cost for heating the home.

Taking into account the constant growth of utility tariffs, an individual meter will help you save a lotAt heating plants, such devices have long been installed to control the quality of services.

Apartment buildings are also required to have heat meters to encourage energy saving measures. Installing a heat meter allows you to check how correctly the coolant is supplied into the house, detect and eliminate possible losses from improper installation and wear of the heating main.

Types of heat meters based on their operating principle

General heat meters that are installed in houses with centralized heating is large-sized expensive devices. They have a wide diameter for the input and output of pipes (from 32 to 300 mm), as they pass through themselves a large amount of heat carrier. Purchase and installation is carried out at the expense of the residents of the house, and the readings are monitored either by a responsible person appointed by the residents themselves, or by a representative of the utility workers.

For individuals counters the price is much lower. They are designed for lower bandwidth (no more than 3 cubic meters per hour) and therefore much more compact.

Such devices can to be mounted both for the entire apartment (with a horizontal heating system) and for each radiator separately (if there are several vertical risers).

In new residential complexes, apartment heat meters are often installed at the construction stage.

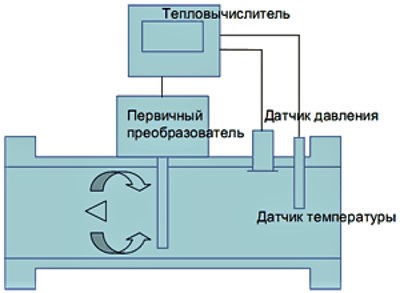

Any heat meter is equipped with computing module, temperature and flow measurement sensors. But according to the principle of measuring the amount of coolant consumed, the meter can be next type:

- electromagnetic;

- mechanical;

- ultrasonic;

- vortex.

Each type of device has its advantages and disadvantages, related to design features.

Electromagnetic

The principle of measurement is based on on electromagnetic inductionThe device is hydrodynamic generator. Due to the influence of a magnetic field, an electric current is excited in water, the amount of heat is determined by the field strength and the potential difference on the oppositely charged electrodes. Due to high sensitivity the heat meter requires very high quality installation and regular maintenanceWithout periodic cleaning, the readings will show an increasing error.

Photo 1. Electromagnetic heat meter Fort-04 with 2 flanged flow meters from the manufacturer Thermo-Fort.

The heat meter can react to nearby electronic devices. It has high precision accounting for many parameters. Works both from the mains and from batteries. Most compact type of heat meter. Recommended for installation at high pressure in the system. Installation is possible at any angle, but subject to the constant presence of a coolant in the installation area.

Reference. If diameter of pipes heating and meter flange does not match, then it is allowed to use adapters.

Mechanical

Flow meter in such a device rotary type (vane, turbine or screw). The operating principle is similar to a water meter, but in addition to the quantity, the temperature of the water passing through the mechanism is also taken into account. The advantages of this type devices in the following:

- low cost;

- energy independence (powered by batteries);

- absence of electrical components (allows installation in adverse conditions);

- vertical mounting option.

A little increases the cost device mandatory installation of a mesh filter, without which the internal mechanism quickly becomes clogged and wears out. Due to the impossibility of using it in conditions of high hardness and contamination of the coolant with rust, mechanical meters are only allowed to be installed as individual ones.

To the essential disadvantages applies to no storage of information per day, and also remote reading impossibility data. In addition, the device is very sensitive to water hammer, and pressure losses in the heating system are higher than in other types of models.

Ultrasonic: can measure and regulate

The measurement is being carried out using ultrasound. Depending on the flow rate of the coolant, the time it takes for the ultrasonic wave to travel from the transmitter installed on one side of the pipe to the receiver located opposite changes. Device does not affect the hydraulic pressure in the systemIf the coolant is clean, then the measurement accuracy is very high, A the service life is practically infiniteIf the water or pipes are contaminated, the error in heat meter data increases.

Photo 2. Ultrasonic heat meter ENKONT with a primary flow converter made of stainless steel, manufactured by AC Electronics LLC.

Great information content such a meter, and the device readings can be read remotely. But you will have to spend money on a UPS, since the device only works from the mains. There are models with additional regulation function water supply on two different channels. This allows you to change the speed of the coolant and the degree of heating of the radiators. Due to their reliability, ultrasonic devices have become widespread, despite the high cost.

Vortex

The operating principle is determined by a physical phenomenon vortex formation when water meets an obstacle. It is activated permanent magnet, which is placed outside the pipe, triangular prism, mounted vertically in the pipe and measuring electrode, a little further along the coolant flow.

Water flows around the prism forms vortices (pulsating changes in flow pressure). Based on the frequency of their formation, information is derived about the volume of coolant that has passed through the pipe.

The advantage of this type of heat meters is independence from pollution pipes and water. This allows you to accurately measure the temperature in old houses with worn-out iron heating systems.

It is installed on both vertical and horizontal sections of pipes. The operation of the device is affected only by sharp changes in the flow rate of the coolant and large particles of debris or air in the system. Energy consumption device minimum and one battery will last for several years of operation. Indications and Malfunction signals are transmitted remotely via radio communication.

Accounting for the required amount of heat in an apartment

The amount of heat is calculated using a heat calculator. The program works according to an algorithm, which The following factors influence:

- type of coolant in the system (steam or liquid);

- type heating systems (closed or open);

- structure systems through which heat is released.

The calculation is relative, since it is formed from a set of individual quantities and at each stage inevitably arise errors (normally up to ±4%)The measurement principle is based on the fact that when passing through the heating system, the coolant gives off heat to the premises, and it is this heat that is considered to be consumed by the consumer.

The quantity is measured heat in Gcal/h (gigacalories per hour), when the mass of the coolant that has passed through the device is taken for the product, or in kWh (kilowatts per hour), if the volume was recorded. According to the following formulas:

Q=Qm×k×(t1-t2)×t (Gcal/h) or Q=V×k×(t1-t2) (in kW/h).

Qm — weight in tons,

t1 — temperature at entry,

t2 — outlet temperature,

V — volume in cubic meters,

T — time in hours,

K — thermal coefficient according to GOST,

Q — the amount of heat given off to the premises.

Basic requirements for apartment appliances

The main requirements for heat meters are: legislative norms. The brand of the device must be present in the register of those permitted in the commercial sphere. A conclusion from the civil service is required. metrology. Installation of heat meters is carried out only by licensed companies.

Important! Verification of metering devices is carried out every 4 yearsIf you miss a date, the readings will not be taken into account.

Useful video

Watch the video, which discusses the main features of installing a heat meter.

What to look for when choosing a heat meter for heating?

First of all, it is worth thinking about necessity individual device. If a common house is installed heat meter, then the costs of purchasing an apartment one are not justified. There is little benefit from the metering device in housing on the first and last floors, and also in corner rooms, if they are not insulated beforehand. With a vertical heating system with separate risers in each room, the costs of installing the meter will greatly exceed the potential benefit.

If you purchase the device it is advisable, then when choosing it is worth it pay attention to the following criteria:

- sensitivity to dirt in the coolant;

- energy independence;

- measurement error;

- pressure loss;

- lengths of straight sections of heating pipes;

- the presence of an archive and its depth;

- self-diagnosis capability.

It is also important that operation and verification of readings were available to the average consumer. It is a good sign if the manufacturer provides warranty beyond the standard 2 years.

Most modern heat meters meet the requirements. All that remains is to choose the right price.

Comments