How to raise hot water to the upper floors? Advantages of a pump for a heating battery in an apartment

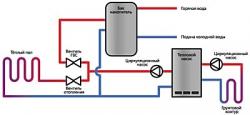

Forced circulation of liquid in complex and extended circuits is provided by a circulation pump. Its main function is uniform heating of the entire house.

At the same time additional load on the gas boiler is removed and noticeably the diameter of the pipes used in the system is reduced.

Advantages of using a multi-storey building in an apartment

This device has a number of advantages:

- Automatic uninterrupted operation mode.

- Doubles the energy saving rate. This is acceptable when specifying certain parameters to the device.

- Increasing the efficiency of the heating system.

- Silent operation.

- Possibility of controlling the room temperature is carried out by rotating the device. This function is present even in pumps without automatic mode.

- The coolant is water or ethylene glycol. Their permissible temperature varies in the range from +2 to +130 °C.

- Providing the required pressure.

- Long service life. Rational operation of the unit will allow you not to think about its repair several years.

- Versatility. This device is suitable for all heating systems.

- Adjusting the system.

Types of circulation pumps for the return system

Exists two main varieties.

With dry rotor

They supply the coolant with great force. They are most often used to move coolant. In such devices, the coolant does not contact the motor.

In dry rotor devices there are Three-phase motors and built-in electronic unit. Their rotation frequency is regulated by an external electronic system.

Such devices are divided into 3 types:

- Block. They are a low-pressure centrifugal pump with a constant rotation speed and a built-in air-cooled electric motor.

- Console. They differ from other types by the presence of an axial input and radial output of the coolant from the device. The motor and pump are fixed by separate fastening units to the foundation slab. The nominal bore of the suction branch is larger than that of the discharge branch. Depending on the type of coolant, it is permissible to use a gland seal or STU.

Photo 1. The WILO-CronoNorm NL console pump (Germany) is best suited for municipal water supply systems.

- Vertical. The nominal bore is the same for suction and discharge type nozzles located on the same axis. Inside such pumps there is a flanged electric motor with air cooling. The vertical devices are mounted on the pipeline.

With wet rotor

This type is widely used in private homes. Inside the device there is water cooling of the electric motor. The fluid passing through the device also lubricates the parts.

On the shaft of the electric motor fixed closed impeller. It is housed in a cast iron or steel housing. It consists of from two parallel disks with holes. One contains the working fluid, and the other is for mounting the wheel on the shaft of the electric motor. The disks are connected to each other by radially curved blades.

The body of such a pump contains confuser for transferring kinetic energy coolant into static pressure and liquid drainage.

An impeller cooled by pumped water is attached to the rotor shaft.

Between the motor stator and the rotor placed separating glass. The rotor itself is mounted on the end plain bearings.

Air is removed from the device using screw plug, which is located on the front wall of the engine housing.

The wet rotor device is working exclusively in a horizontal position.

The principle of operation of the pump on the pipes of the heating battery

It looks a lot like action. drainage device. This device captures the coolant on one side and pumps it into the pipeline on the other. The entire process occurs due to the centrifugal force that appears under the action of the rotation of the blade wheel. creates a vacuum in the suction pipe, which ensures circulation and flow of liquid into the suction line.

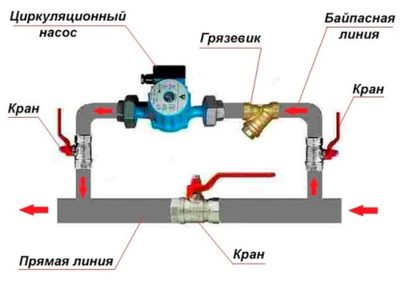

Important! The pump installation must be carried out in front of the boiler, on the return line. This is done so that the device does not take in air from the boiler, in which boiling may occur. In addition, with such installation, the device will work at lower temperatures.

They do it at the installation site bypass. Its diameter is smaller than the diameter of the main pipe. After installing the bypass, you can begin the standard installation of the circulation equipment.

How to choose

Parameters to pay attention to when purchasing the device:

- Power. This indicator is influenced by: the degree of liquid pressure, boiler performance, its throughput, coolant temperature, and pipeline diameter.

- Consumption circulation pump. It is determined by the formula: Q=N/t2—t1, Where N — power parameter, t2 — the temperature coming out of the heat source, and t1 — present in the return pipeline.

- Pressure pump. In accordance with the standards per 1 sq. m. of area the room requires a power value 100 W.

- Connecting the device. Important pipe diameter to fix it - 2.5 or 3.2 cm.

- Pressure. Length of all pipes multiplied by 100 Pa.

- Performance.

Useful video

Watch the video to learn what calculations will help you choose the right circulation pump.

Pump options for radiators in an apartment building

To make the right decision, you need to consult a specialist, pay attention to all selection criteria, calculate them correctly. And only after that consider suitable options.