An alternative to expensive electric furnaces - a gas stove for a bath: features of the device

Building your own sauna on a country plot has long become a tradition - without a pleasant evening in the steam room, a vacation at the dacha can no longer be considered complete. When building a sauna, it is especially important choosing the type of furnace.

The speed of heating the room, the quality of the heat produced, and the amount of steam depend on the type of heating element and its design. Although it is traditionally believed that there is no better option for a bathhouse than a wood-burning stove, its installation and subsequent maintenance are often associated with a number of difficulties, as well as significant costs.

Therefore, the installation of gas devices in the bathhouse is becoming increasingly popular - this is a much more economical heating device in terms of fuel consumption, as well as an easy-to-use heating device.

Construction and operating principle of a sauna stove

The gas stove provides all the functions necessary for a steam room, including convenient adjustment of the heating level, while being compact and aesthetically pleasing. One of the main advantages of this option is availability such fuel as gas, it low cost, environmentally friendly (unlike firewood, gas burns completely, without an unpleasant smell, and leaves no waste).

Photo 1. A metal gas sauna stove takes up little space in the room due to its compact size.

Gas appliances are built from both brick and metal. The first option has the advantages of greater heat capacity, long-term heat transfer, but will require long heating to the optimum temperature.

Metal gas devices are more common due to their compactness and high efficiency, but in order to make the stay in the steam room more comfortable and increase heat accumulation, it is recommended to build a brick screen around the stove.

All types of devices have a similar design:

- body made of sheet steel with thickness 3 mm;

- the combustion chamber where the gas is burned – the walls of this compartment are usually made made of extra strong steel 5 mm thickto avoid burnout;

- fuel channel – is located so that it can be conveniently carried outside or into an adjacent room, where the channel is connected to a cylinder or main line;

- gas hob with burner – attached to the fuel channel, the burners are located in the combustion chamber;

- thermostat – allows you to regulate the flame size; in some models, it automatically turns off the burner when the firebox overheats;

- stone compartment – usually installed directly above the firebox, can be either open or closed;

- pipe branch - like a chimney, it removes heated air outside; a water heating tank is often installed in its lower part.

The operating principle of the gas model is very simple - fuel is supplied through a channel into the combustion chamber, where, burning, it heats the walls of the device, as well as the stones in the compartment located at the top, and the chimney pipes.

The body of the stove is always made larger than the firebox; special openings in the bottom and top allow for air circulation – cold air enters from below, heats up near the walls of the firebox, rises and exits into the atmosphere of the steam room.

Gas burner

The fundamental part of the device’s design is the gas burner, which partly determines fuel consumption, which means the efficiency of the device and its cost effectiveness.

For gas combustion, a constant supply of air is required, which is why burners are divided into two main types:

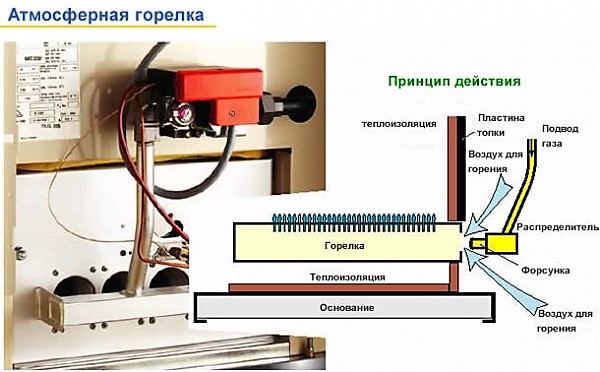

- Atmospheric – the most common, due to its simplicity, availability, independence from electricity. The design consists of a branch, through which gas is supplied to the chamber under pressure, and a piezo igniter. For the correct operation of the burner creation of high-quality traction is required (it is better to take air from the adjacent room using a ventilation pipe). Simplicity the design turns it around low efficiency – it is often impossible to create the required level of draft, the gas burns poorly, most of it goes into the chimney pipe, also creating the risk of leakage.

Photo 2. External appearance of the atmospheric gas burner for the furnace and the diagram of the device’s operation.

- Burners with blowing – a ventilation system and a mini-fan are used to ensure uninterrupted air supply. Such a burner requires connection to the power grid or installation of a battery, which affects the overall cost of the device. Fan burners significantly improve the quality of gas combustion, reduce its consumption, improve efficiency heating element. By connecting to electricity, sensors and thermostats are installed on them, which allow the burner's operating intensity to be automatically adjusted.

When installing a burner of any type, it is better to choose long elongated shape of the branch – this will increase the flame area and allow the walls of the firebox to heat up faster.

Criteria for choosing a sauna stove

To correctly select the most suitable model of gas appliance, the following factors are taken into account:

- Steam room area – the power of the device directly depends on the size of the room (one cubic meter of air produces one kilowatt of power).

The quality of the thermal insulation of the steam room and the presence of windows that cause heat loss and, accordingly, require an increase in the power of the heating device are taken into account.

- Heat capacity of the furnace – an important factor that allows for better heating of the room, as well as effective drying of the steam room using residual heat. Brick models have the highest heat capacity; in the case of a metal device, the presence of a screen, the location and length of the branch pipe, and the type of heater are of great importance.

- Fuel consumption – depends mainly on the power of the furnace, average figures for a small steam room and a 10 kW device: 1.5–4 cubic meters/hour. When heating a fairly large room for several people, more powerful stoves with two or three burners are usually used, and gas consumption increases several times. Increasing the heat capacity of the stove helps reduce losses.

To increase safety and save space in the steam room, it is recommended to choose a model with remote fuel channel, allowing you to place part of the equipment behind the wall. This will also provide more convenient control of the fuel supply, and the necessary maintenance of the device.

Wood and gas stoves

Very often a combined version of the stove is installed, usually equipped two fireboxes.

This provides the possibility of both the traditional method of heating – by burning wood, pieces of peat and other solid fuel, and heating with a gas burner.

Often, such a universal model is obtained by re-equipping an existing sauna stove, usually a brick one - its design almost does not have to be changed, only a gas channel is supplied for additional heating and a burner is installed.

Reference! Burning wood, especially when using a brick oven, gives a softer heat, which is healthy and creates a special comfortable atmosphere in the steam room. Therefore, many people do not want to give up this method of heating when building a bathhouse, although using gas is much more profitable.

The installation of a combination furnace is very convenient when there is a fire on the site there is no installed gas main and heating is provided by imported liquefied gas from cylinders. Then the possibility of heating the bathhouse with wood will provide insurance in case of interruptions in fuel supply.

The design of a metal gas-wood stove is almost no different from a regular mono-fuel stove. The difference is the ability to remove the block with a gas panel, turning the gas firebox into a regular wood-burning one. An even easier-to-use option with the installation of an additional fuel receiver is common.

Selecting a combined design

As in the case of a mono-fuel device, the following conditions are taken into account when choosing:

- Steam room area – depending on the size of the room, the furnace power is calculated for each type of fuel.

If the wooden or tiled walls of the steam room do not have thermal insulation of the surface, the furnace power is selected to be one and a half times greater, in order to heat them up properly and create the right microclimate.

- Heat capacity – combination stoves are often built of brick, which increases their ability to retain heat, and therefore save on fuel. When choosing a metal model with two fireboxes, it is recommended to lay out a brick lining.

- Fuel consumption – for wood stoves, on average, it is required about 4 kg of firewood per hour, if the area of the steam room does not exceed 20 sq.m. To reduce fuel consumption, the heat capacity of the furnace is increased - this will increase the heating time, but reduce heat loss.

Due to their versatility and multifunctionality, combined stoves do not lose popularity in baths in suburban areas. When choosing this option, it is recommended to calculate in advance where the fuel for the stove will be stored (you will need space for both gas equipment and firewood).

Installation in a bathhouse

If you want to install a gas-powered device in the steam room, you will first have to get permission in a specialized gas supply company.

Its employees will check the correct placement of the device in the room and compliance with all safety measures.

When choosing a location for a sauna stove, you must follow these rules:

- the walls around the stove are carefully closed fire-resistant material, a non-combustible base must be installed on the floor;

- height of fireproof base 10 cm above floor level;

- the device itself is installed at least half a meter from the walls;

- availability adjustable traction in the combustion chamber;

- the best option would be to position the stove so that its entire front side is in the dressing room, and not in the steam room - this will protect the stove from exposure to a humid atmosphere, make it easier to operate and increase safety;

- in the dressing room they always set things up high-quality ventilation;

- All pipeline joints are checked for perfect tightness to avoid dangers of gas leaks;

- The pipes connecting the stove to the chimney are insulated especially carefully when passing through the ceilings and roof.

Important! Compliance with all requirements will allow you to install a gas furnace with a ventilated burner without much difficulty. In case of using an atmospheric burner the risk of a dangerous situation occurring is significantly higher, and the inspection of the premises will be more thorough and strict.

Useful video

In the video you can learn how to properly and safely use a gas and wood-fired sauna stove.

Top producers

The most popular models on the market are those of modern Finnish stove manufacturers – their products are characterized by consistently high quality and functionality. But our country also offers worthy analogues – the companies Teplodar, Termofor, and Kutkin have a good reputation.

Photo 3. The gas oven from the Russian manufacturer Kutkin is very popular.

Installing a gas stove for a bathhouse guarantees ensuring fast and efficient air heating indoors, reliability and ease of use.

Attention! Gas stoves allow you to easily regulate the temperature of the steam room, and the automatic sensor will protect the device from overheating.

This type of stove is compact and will not take up extra space even with a small bathhouse; modern models look very aesthetically pleasing and will fit well into the interior of a steam room or sauna. Versatility combined options of devices will provide greater freedom and independence from the availability of fuel - you can choose the type that is more accessible at the moment.

The peculiarity of gas-wood stoves will also allow you to select the desired microclimate properties in the steam room - gas will provide strong, even heat, and heating with wood will provide gradually increasing heat.

Comments