Unusual muffle furnace will process any material

You are viewing the section Muffle, located in the large section For production.

A muffle furnace is a device designed for heat treatment of various materials.

It differs from a conventional heating structure by its muffle, a compartment that reliably protects the heated substance from direct contact with combustion products.

Content

High temperature muffle furnaces

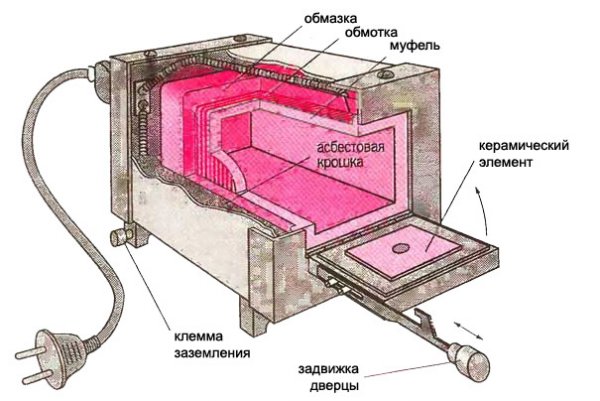

The product to be heat treated is placed in a muffle made of a special refractory material, such as ceramics or corundumSuch materials have an extremely high thermal conductivity coefficient and good density.

Photo 1. Schematic diagram of the electric muffle furnace: both the external and internal sides are shown.

The air inside the muffle is heated to a certain temperature, which is maintained at one level until the end of firing. Heating elements in the form of wire are responsible for the supply of thermal energy. Next comes a layer of heat-insulating material, mainly made of SHVP/SHVPH.

Some manufacturers equip their devices with powerful ventilation systemsA separate exhaust mechanism is responsible for removing steam and smoke.

The entire structure is covered with a reliable metal body with a thickness of approximately 1.5-2 mm. To achieve high temperature (over 1150 °C) manufacturers began to produce muffles from a special fibrous material. Its significant disadvantage is its short life.

Under the influence of gas fumes and other chemicals, the fiber structure soon loses its shape. There are also fireclay muffles with heaters hidden in the grooves of the lining.

Reference. The volume of the inner chamber may vary from one to two hundred liters. Large structures take longer to heat up than miniature models. Large furnaces consume more electricity, since some of it is spent directly on heating the muffle.

Types: gas, electric, with a temperature of 1100, 1300, 1700 degrees

By purpose:

- Muffle furnaces. Designed for processing specific materials at high temperatures.

- Drying cabinets. Maximum temperatures are lower than in muffle furnaces. They are used for drying, heating, calcining and testing various materials in an air environment.

By type of energy source:

- Gas. Allows significant savings in fuel consumption.

- Electric. Most often used in large enterprises. Tapes, wires, rods, profiles and tubes for such furnaces can be made of platinum alloys, tungsten, molybdenum, tantalum, nichrome and fechral alloys, lanthanum chromite, yttrium chromite, scandium chromite. Their power supply 220 or 380 volts, depending on the size of the camera.

By heating temperature in degrees Celsius:

- Moderate temperature - from 100 °C to 1100 °C.

- Average temperature - from 100 °C to 1300 °C.

- High temperature - from 100 °C to 1700 °C.

By design:

- Horizontal loading/simple — are loaded from the side. They have virtually no competitors in terms of the number of fireboxes heated in the furnace at the same time.

- Top Loading/Pot — loaded from the top, not separated from the hearth. Provide more efficient work with shock packing masses and rapid release of combustion products.

- Cap-shaped - loaded from the top, separated from the hearth after heating.

By processing mode:

- Air, where the muffle limits the movement of air masses between the heaters and the working space.

- With a gas atmosphere, where the gas can be nitriding, inert, reducing, etc. The most commonly used gases here are hydrogen, nitrogen, argon, and helium.

- Vacuum, where a rarefied space is artificially created in the inner part of the muffle.

They come in different capacities: 1.5 - 3 kW; 6, 18, 26 kW.

There are also different sizes of ovens: 200 x 300 x 200; 300 x 300 x 300; 400 x 300 x 400 and others.

Worthy of special mention are laboratory muffle furnaces. They are characterized by high technical equipment, the ability to instantly replace the muffle and almost ideal accuracy of operating parameters. Such designs are used to conduct experiments to find out how to improve a particular product.

Laboratory muffle furnaces are extremely heat up quickly to the required temperature. As a rule, they are equipped with timers. Their chambers need to be changed frequently, since each raw material requires special heating conditions. The bottom of such a device should be equipped with silicon carbide plates and an additional tray to protect the heating elements.

Attention! Operation of muffle furnaces is possible at the temperature regime from +5 °C to +40 °C. The permissible level of humidity in the room should not exceed the mark of 85%.

How to work with the oven? What is the thermocouple for?

Working with a muffle furnace is quite simple. — all you need to do is open the lid/door and place the material inside. Then you need to connect the equipment to the power grid and set the desired temperature, then close it. If transportation is necessary, the device is carefully packed.

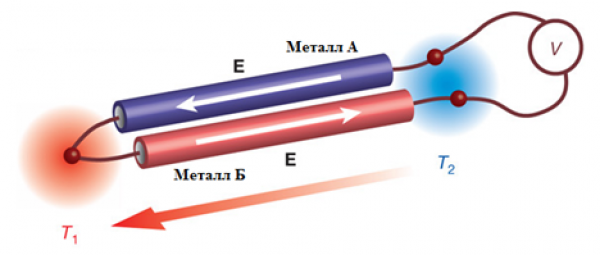

Photo 2. Thermocouple diagram for a muffle furnace. Two pieces of metal are used, which are connected to each other.

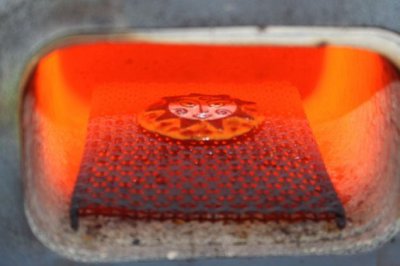

To measure the temperature in a muffle furnace, a thermocouples. It consists of two pieces of wire made of special alloys welded together. When heated, the thermocouple produces electricity (the higher the temperature in the furnace, the more millivolts we get at the output). These millivolts can then be measured with an appropriate device and converted into temperature.

Applications: from chemist to jeweler. Fume hoods

Muffle furnaces are often used in the final stages of processing ceramic products. in pottery and art workshops. They are actively used. in blacksmithing.

In the chemical industry The devices are used to create single crystals, cupellation, and also to detect precious metals in various alloys and ores.

In medicine They are indispensable for sterilization and disinfection of instruments.

They are no less popular in the field of jewelry productionThe automatic controller allows you to heat and cool products slowly, without any temperature jumps.

At home These structures are ideal for hardening cutting parts of household tools - knives, saws, scissors. Muffle plates can be installed and used for personal needs in private houses and apartments, because they are very adaptable.

The scope of application of muffle furnaces includes:

- dispersion hardening;

- homogenization and normalization;

- mineralization and drying;

- cupellation and cremation.

Muffle furnaces do not allow high-speed material processing modes. They cannot be used for heat treatment of metals with the need for periodic unloading of raw materials, since this is associated with the constant opening of the lid/door. The devices have a very important property in the modern world - almost complete chemical neutrality.

It is better to place the muffle furnace in a special fume hoodIt allows for the effective removal of vapors and other combustion products, thereby protecting people from their harmful effects.

Additionally, the cabinet can be equipped with a metal cabinet for storing various auxiliary equipment, consumables, and tools.

Examples of models: 220 and 380 volts; 2, 3, 4 kW; 50, 400 liters

Muffle furnace "Volcano", manufacturer Aveyron.

- nutrition 220 in;

- power 3000 W;

- operating temperature up to 900 degrees;

- dimensions - 330x300x510;

- volume 50 liters.

The company also produces heating elements for muffle furnaces.

Muffle furnace Argenta APE 800 with programmable control

Photo 3. Muffle furnace Argenta APE 800. A programmer is installed on the side wall, with which you can control the device.

- 2 control programs;

- chamber volume 400 liters;

- power 2.4 kW;

- nutrition 380 in;

- maximum temperature 800 degrees.

Muffle furnace Snol 7 2

- nutrition 220 in;

- power 4 kW;

- maximum temperature 1200 degrees;

- dimensions 550x575x540.

Muffle furnace PE-4820, manufacturer "Ecohim"

- volume 7.2 liters;

- maximum temperature 1000 degrees;

- nutrition 220 in;

- power 2.4 kW.

Thermoregulators, controllers for muffle furnaces: analog, digital, programmers

The thermostat allows you to regulate the temperature inside the oven. Thermostats are divided into two types:

- analog

- digital

Analogue thermostats are almost never used anymore. They are only supplied with some ovens, for example, PM-8. The regulator is a rotary knob with a mark applied to it, which can be set opposite the required division of the scale. The accuracy of setting the temperature using such devices not large.

Digital thermostats are widely used at the moment. They are divided into into several types depending on functionality:

- Simplified thermostat displays the set or current temperature in the oven on the display. Some manufacturers additionally equip these thermostats with timers.

- Electronic thermostat has two displays, one of which shows the set temperature, the other the current temperature. It is possible to set the holding time and heating speed.

- Programmer similar to an electronic thermostat, but in addition has the ability to set heating programs over time.

Useful video

Watch a video showing how to test the functionality of a muffle furnace thermocouple.