A striking combination of opposites: an old refrigerator is transformed into a smokehouse

The spacious smokehouse will not only provide your family with delicious products, but also will help to store them in large quantities. This is especially true for hunters and fishermen.

In addition, smoking will correct all the shortcomings of slightly spoiled meat and fish. You can make such an invaluable device almost free: from an old refrigerator.

DIY Smokehouse from an Old Refrigerator: Step-by-Step Instructions

Any old refrigerator will do for making a smokehouse. Before you take it apart, decide what type of smokehouse will it be, hot or cold smoked.

The further process of creating a food preparation device depends on this.

To make the first version, you will need a refrigerator metal body only, therefore, everything unnecessary is removed from it: plastic panels and the insulation underneath them.

Remove the radiators and engine. Leave only the door seal. For work use screwdrivers, grinder, crowbar and a garbage bag.

After all operations, thoroughly wash the walls of the box and seal all existing holes in it.

If you decide to make a smokehouse cold smoked, only plastic is removed. Cool smoke does not interfere with foam plastic or mineral wool (insulation materials that may remain in the refrigerator), they will maintain the optimal temperature.

For cold smoked smokehouse It is advisable to install a smoke generator. This device can be purchased or assembled by hand. You will need inexpensive consumables and an aquarium compressor (with optimal performance 60 l/h).

Project selection: hot or cold smoking. Do you need a smoke generator?

A hot smoking smokehouse requires a heat source directly underneath it. You can choose any type of firebox: laid out made of brick, welded from sheets gland, dug out in the ground. To remove smoke from the smoking chamber, use a suitable pipe with a bend. A hole is cut in the refrigerator body and the pipe is attached by welding or some other method.

A cold smoking smokehouse requires smoke at a low temperature, so it needs to be given the opportunity to cool down. For this purpose, the firebox and the chamber are carried distance not less than 3 meters.

The chimney is made from a pipe, corrugated pipe, or simply a trench of the required width is made and covered with any suitable material.

Standard scheme cold smoking smokehouses from the refrigerator:

- smoking chamber;

- chimney;

- firebox.

There is another option for smoking - using a smoke generator, the tube of which is inserted into a hole in the wall of the smokehouse.

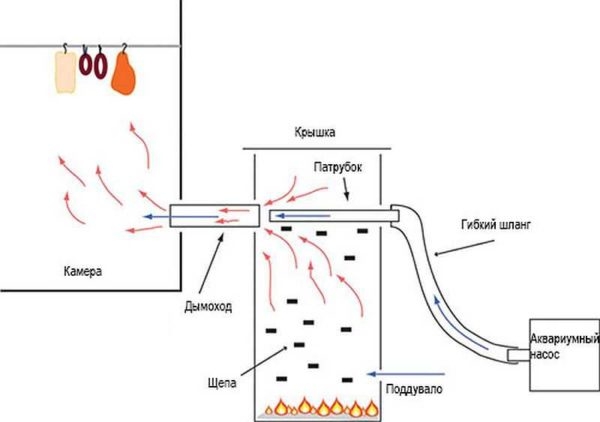

What and how to make a smoke generator. Product drawing

A smoke generator is a device that helps to produce thick smoke. If it is present, the smoking process will be more fast, and its result is more delicious. There are many options for making a smoke generator yourself. You can build such a device from what you have available. Let's consider assembling this homemade device from scrap materials.

To make a smoke generator you will need:

- metal pipe section 130 mm and length 500 mm;

- metal lattice of such a diameter that it fits tightly into the pipe (can be cut from stainless steel);

- bottom cover for a pipe with sides, height not less than 1.5 cm (can be made from stainless steel, thin tin);

- top cover for pipe;

- 3 metal plates length 30-35 cm and not less than a width 5 cm, for the construction of supports;

- 6 bolts section 6 mm and not less than a length 10 mm;

- tee with 1/2 thread;

- screw for fixing the tee;

- coupling 1/2 length 10-12 cm;

- 1/2 nipple with 10 mm outlet;

- metal tube section 5-6 mm and not less than a length 7 cm;

- compressor for aquariums with flexible air supply tube.

Assembling the smoke generator:

- A hole of this size is cut in the lid diameter, so that you can insert the tee and secure it with a nut from below.

- A coupling is screwed into the tee.

- A metal tube is inserted into the nipple and screwed into the tee. The tube should go into the coupling by 1-1.5 cm.

- From the lower plane of the pipe, they retreat in the direction up 25 cm. They drill out 3 holes.

- Stepping back from the holes down 3-5 cm, drill similar holes.

- The supports (metal strips) are fastened one after the other so that each of them is fastened at its upper part. on 2 bolts with nuts. These fasteners are screwed into previously drilled holes.

- The supports are bent so that the pipe takes a stable vertical position.

- Drill into the bottom of the pipe two holes: one for igniting the chips, the second for creating traction. The first one is at a height 25-26 cm, the second at the level of the blower.

- The grate is installed in the pipe so that it rests on the protruding pins of the bolts that are screwed in at a height of 25 cm from the bottom of the pipe.

- They put it on lower lid. It will hold the ash.

- They put it on top a cover with a structure installed on it.

- Shavings or wood chips are placed into the pipe (on the grate).

- Connect the smoke generator to the aquarium compressor.

Photo 1. Drawing showing the structure and operating principle of a smoke generator with an upper ejector.

Cold smoking smokehouse from a freezer and pipes

In addition to the refrigerator body, you will need additional materials:

- metal pipes for the chimney;

- trench covering material (boards, stainless steel sheets, polyethylene);

- material for the construction of grates and hangers for products (thick wire, reinforcement bars, welding electrodes);

- materials for the firebox device (metal sheets, bricks, concrete blocks).

You will need a shovel, a hacksaw, a drill or a screwdriver.

Stage 1. Manufacturing the body.

For a cold smoking smokehouse, you can use a body with insulation, but the volume of this container will be smaller.

Each owner chooses for himself what is more important to him: capacity or cooling rate smoke cabinet.

The stages of work on the installation of a smoking apparatus are as follows:

- They determine place for installation of a smoke cabinet.

- The lower part of the body is cut out hole of such a diameter that it can be inserted chimney pipe.

- For the device traction Several holes are drilled in the "lid" and the bottom of the refrigeration chamber.

Important! The camera should be positioned slightly higher than the fireboxIn this case, a natural draft is created and the smoke will more readily rise into the cabinet.

Stage 2. Installation of the chimney.

In the place where the smoking chamber will be installed, a hole is dug in the ground of such a size that it will accommodate the laid out at a depth of 20-30 cm, chimney pipe. A pipe with a bend is welded to the bottom of the refrigerator.

Stage 3. Manufacturing of gratings.

The smoke cabinet is equipped with everything necessary for storing products: with a lattice and crossbars with hooks. The gratings are made from thick wire or thin reinforcement bars. Individual elements are connected to each other with wire or welding.

Stage 4. Making the pallet.

The pallet is made of a piece of tin, stainless steel, heat-resistant glass. A wide comb is also suitable for collecting fat. frying pan or roasting pan.

Stage 5. Chimney installation.

They dig a trench in the direction of the firebox and extend the elbow with pipes, coming out of the lower part of the chamber body.

At the opposite end of the trench, a hole is dug in the ground. A fire is made in this place, covered with a piece of metal from above. If the chimney is carried out above ground, a brick firebox is built from 2-3 rows of bricksIn the second case, the chimney and the firebox are hermetically connected.

If the design works and from a smoke generator, a hole is drilled in the side wall of the refrigerator body for its connection. The diagram of the device and operation of the smoke generator is given above.

Photo 2. An example of a ready-made smokehouse from a refrigerator. This design can be used for smoking sausages.

Operating recommendations

Regardless of the method of laying the chimney and the design of the firebox, during the operation of the smokehouse it is necessary monitor the fire strength. It is important to exclude direct exposure to wind, so the firebox should be closed on at least three sides bricks or metal sheets.

Useful video

Check out the video, which shows in detail, step by step, how to make a smokehouse from a refrigerator with a motor for regulating the amount and temperature of smoke.

Comments

Such insulation, especially mineral wool, must be removed without fail. Its proximity to the product is simply undesirable. And foam plastic is absolutely unnecessary. The cold smoking chamber does not require insulation. The temperature inside the chamber is regulated by the temperature of the smoke supply.