To make happiness complete: how to make hooks, grates and other little things for a smokehouse

You are viewing the section Components, accessories, located in the large section Smokehouse.

Smoking is one of the most delicious methods of cooking.

Few people would refuse smoked fish, ham, lard and other delicacies that exude wonderful aromas. There are several types of smoking – cold, hot and semi-hot, they determine the final taste of the product.

The choice of one or another option is strictly individual, so we will consider the manufacture of a standard smokehouse that allows you to cook various products. Of course, you can buy the product in the store, but a homemade smokehouse will be more economical option.

Content

Smokehouse design

A standard homemade smokehouse is a device that includes several components:

-

Pallet. The container is installed at the bottom of the grate. During the smoking process, fat drips from the products, and if you do not place the container under the grate, it will fall directly onto the burning coals, which is unacceptable.

The issue here is not that the wood will go out, but that the fats, when evaporated, are absorbed into the food and can reduce the benefits of the food.

- LatticePieces of chicken, fish, etc. are placed on it.

- ThermometerAllows you to control the temperature during the smoking process.

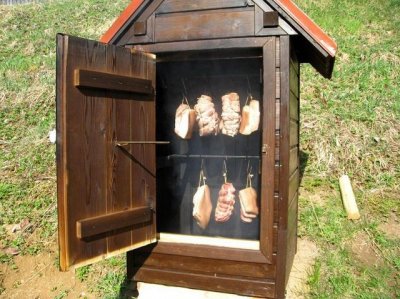

- ClosetSmoking must take place in a closed space, so it is necessary to make the smokehouse body itself.

How to build everything with your own hands? Materials and tools

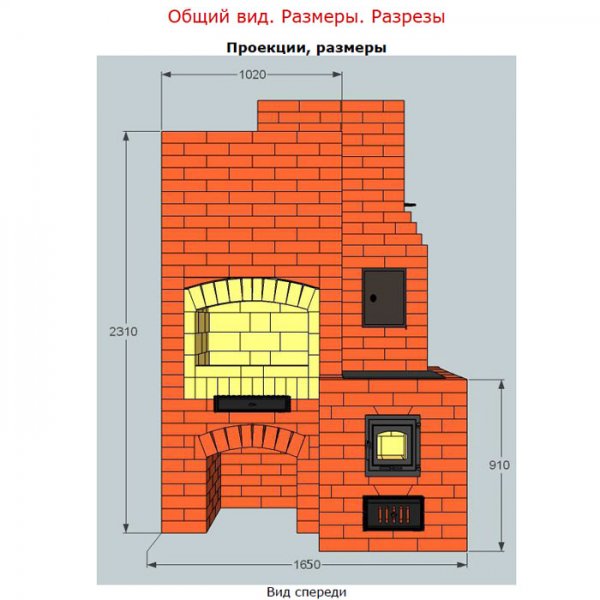

If we are considering the option of a stationary smokehouse, the most reliable structure would be brick. It can be made in a variety of sizes, depending on how much material you have, i.e. brick. If there are no problems with it, then you can build something like a small brick house with a smokehouse, this will certainly become a decoration of your summer cottage.

Preparatory work begins with choosing the right location for the building. The choice must be based on the principles fire safety, i.e. build the device away from other buildings - utility and residential. The place must be cleared of dry grass and foreign objects.

Before you begin planning a rough layout of the structure, it is important to make sure that you have all the necessary materials and tools:

- BrickTo make the smokehouse last longer, it is better to use fireproof bricks.

- To prepare the solution you will need a standard set of sand, cement and clay.

- Wooden bars and beams.

- Sackcloth.

- Metallic corners.

- Spatula.

- Hammer.

- The container in which it will be cooked cement mortar.

- Hacksaw, tape measure.

- Trowel.

Photo 1. Approximate drawing of a large brick smokehouse with barbecue. Possible dimensions are indicated nearby.

Foundation

The structure will be stationary, so it is impossible to do without pouring the foundation. To begin with we mark out the territory along the borders of the future smokehouse, driving in stakes and also pulling a fishing line between them.

We will be making a small smokehouse, so depth the foundation will be 400 mm. We prepare a solution using a mixture of sand and cement, add crushed stone there. Fill it all with water until it is slightly thick. The smokehouse is characterized by a low load on the foundation, so this solution is quite sufficient.

Important! To ensure the necessary waterproofing foundation, and it needs to be covered with roofing felt on top.

After the foundation has hardened, you can install wooden formwork on top, which is slightly larger than the size of the base.

Chimney

The chimney is one of the main components of any smokehouse, regardless of its dimensions. For it, you need to dig a trench with the following parameters:

- length - from 250 to 300 mm;

- width - 500 mm;

- depth - from 300 to 400 mm.

After you dig the trench, its bottom must be carefully tamped. Next, lay a layer of bricks using clay mortar. You must understand that the chimney will come out with one end to firebox, where the wood will burn, and others - to smokehouse.

Important! Remember that the smokehouse where the products are prepared must be located above the firebox.

The chimney should rise to the cabinet in such a way that from the starting point to the end point there is about 9 degreesThe side walls of the chimney are lined with bricks so that they rise by 250 mm above ground level. The chimney must be closed, so we close it with bricks and mortar.

Reference. After the solution hardens, we fill the upper part of the chimney with earth. The layer is about 140 mm. Remember that the chimney should enter the smokehouse at a small distance - by 300 mm.

Stove cabinet. Do you need drawers?

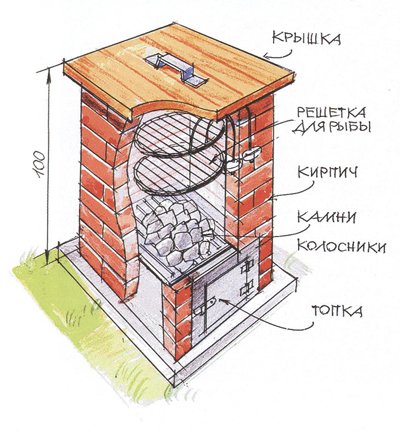

The smoking chamber can be laid out in various shapes, but it is better to use a standard one - in the form of a square. The dimensions will be 1 by 1 meter. Height small - about 1.5 meters.

For brick laying it is better to choose clay based solution, because it is a natural material. When laying bricks, you need to place them on edge - this way you will save material.

When laying, it is necessary to take into account that in the upper and middle parts there should be metal pins, on which a grill will be installed or hooks will be hung on which food will be smoked.

We place the pins between the bricks and then seal them with mortar. It is best to make two tiers so that you can cook more food.

When laying, it is worth considering that there will be a grate installed under it drip tray. Therefore, it is also necessary to provide fastenings for it. The roof of the smokehouse can be removable, made of sheet metal or solid - made of bricks. If you choose the second option, it is necessary to provide ventilation holes so that they can be opened and closed.

Firebox

The firebox should be located at the other end of the chimney. It is made of iron sheets. The dimensions are as follows:

- length - 400 mm;

- width - 350 mm;

- depth - 350 mm.

At the bottom of the firebox we arrange an ash pan, where ashes and cinders will be located, i.e. the remains of burnt firewood. By the way, the ash pan also serves as a blower.

Doors

The doors need to be made in advance, using wooden materials and metal lining. In order to install them on the smokehouse, it is necessary to use metal corners that are welded to the brick.

To the door using nuts and bolts they screw the latch on for closing and a shutter plate. The door, made in advance, is attached to the main frame using a special movable loop.

When performing this procedure, it is necessary to take into account that the main factor of fastening is tight fit doors to the edge of the entrance.

The exact location of the latch is determined, and a thin reinforcement loop is welded to the body. The door itself may not have holes, and instead of them, for good traction, you can make a specially closing hole. This is where the door manufacturing process ends.

Pallet

The tray functions as a container that collects fat dripping from food. To make the tray you will need stainless steel sheet, which will be a couple of centimeters smaller than the dimensions of the cabinet so that it can be freely placed inside.

We make cuts along the edges of the sheet so that the right angle is divided in half. Then we simply bend all the sides upwards to form sides. Their joints need to be boiled so that the fat does not leak out of the container. Remember that the size of the sides should be at least 3 cm.

Stand for smokehouse

The stand is made in the event that we are not making a stationary one, but mobile smokehouse, and the products will be prepared by hot smoking, not cold smoking. The stand is located between the firebox where the wood burns and the smokehouse. As a stand, you can use ordinary bricks.

The stand can be made from metal corners. First, the base is welded according to the dimensions of the smokehouse. This means a cabinet made from metal sheets. Then we weld four ribs to the corners of the base so that the stand can be installed on the ground. Length these edges can be different, but the optimal value is from 30 to 50 cm.

What to make the gratings from?

As for the grate and other small components, they can be made from metal rods or wire. Ready-made grates are available in many electric stoves, so you can borrow from there.

If we make a grid from pieces of reinforcement, we need weld them together using a welding machine. For this purpose, reinforcement rods are installed crosswise.

The grate should be slightly smaller than the dimensions of the smokehouse so that it fits inside without any problems.

You can follow the advice and use a reinforcing mesh to make the grate, section It is optimal to take rods 4 mm, cell 50x50 mm. This is the best calculation, when 3-4 chickens are placed in the smokehouse. You can worry about convenience and weld the corners, which serve as a stop, directly on the sides of the smokehouse, or you can put it on a pallet, having previously bent the "legs" from the protruding edges of the reinforcement.

Hooks

Hooks are needed to hang lard, ham and other products that are preferably cooked in a suspended state. If there are no ready-made options, they are also can be created from small diameter metal rods, bending them accordingly. You can use thick wire, but you need to check its strength so that it can withstand the weight of the product.

Installing elements on an electric smokehouse

First you will need transformer from an old TV. In addition, the following components are needed:

- voltage multiplier;

- resistor - from 100 ohms to 7 kOhms;

- transistor - CT 836;

- insulated network cable;

- ebonite insulating rings;

- metal mesh.

Control unit

The power supply for the device is made on the basis of a resistor and a transistor, which are connected to the terminals of the transformer - to 9 and 11, if counted counterclockwise. To conclusion 12 the positive pole of the power supply is connected for 12-24 volts.

The control unit automates the transfer process current 220 V to the heating element. It is this element that provides the required temperature in the smokehouse, periodically switching off the heating element.

Fan

A fan is needed to transfer smoke into the smokehouse. This task is perfectly handled by a regular computer cooler, but choose an element with larger dimensions.

The installation process is quite simple. It is necessary to place the fan two-thirds of the height from the bottom of the smokehouse, take care of the proper protection with a pipe or grate. There is no need to invent any design features - the device is simply cut into the back wall. The best option is fan from an old electric ovenIt is reliably protected from overheating and its power is quite sufficient.

Photo 2. If you remove the baking trays, you can see a large fan on the back wall of the electric oven.

What criteria should smokehouse components meet?

Anyone can choose one of the possible options for making a smokehouse. It is worth considering the compliance of all elements of the smokehouse with important criteria. For example, it is necessary to correctly calculate the type of foundation, the specifics of the chimney, the structure of the stove cabinet itself, etc. Some of the main criteria are correct placement firebox, chimney angle.

Useful video

The video demonstrates the operation of a homemade smokehouse with a high-voltage generator. The difference between electrostatic smoking and conventional smoking is shown.

Comments

This thermometer is quite inexpensive, but it allows you to control the process. And the product is truly cold smoked, not semi-hot.

I can make exclusive things for friends, not ordinary grates, but exclusive or custom-made. I made a smokehouse from a barrel, and welded everything else from metal for it. It turned out to be a cool round grate, like in this article, only of course it is different.