Enjoying smoked meats! Making a smoke generator for a smokehouse with your own hands

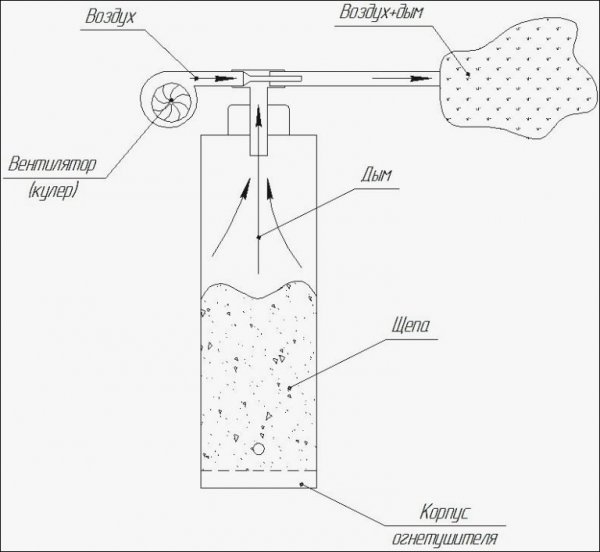

The smoke generator, which is part of the smokehouse, is designed to create smoke masses.

It works through two processes: heating sawdust And smoldering without the use of oxygen. You can make it yourself using a metal pipe, an ejector that creates thrust, and a compressor.

Content

What is included in the device of a smoke generator for cold and hot smoking?

The smoke generating device consists of the following components:

- A body that is a cylindrical or square container. The best material for making a smoke generator is stainless steel, but other metals or alloys can be used. the main element of the design, so special attention should be paid to it during assembly. The body must correspond to certain dimensions, be airtight and contain the required amount of fuel.

- The chimney is mounted on the body and is designed to remove smoke from the ejector into the smoking chamber. This component is attached using a welded seam. It should be perforated or include a tightly wound spring. With this element, you can regulate the supply of smoke mass to the smokehouse; special attention should be paid to the chimney when assembling.

- The ejector is used as a tool to create the required thrust..

- The compressor serves to improve the performance of the previous element. and mixing oxygen with the smoke mass produced inside the body.

Each part of the smoke generator performs its own functions and if one is missing, the operation of the entire installation is disrupted.

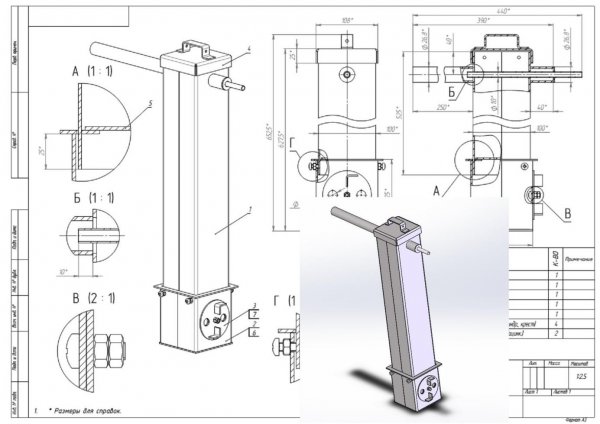

Photo 1. Homemade smoke generator for a smokehouse, the body of which is made from a square container.

Smoke generator creates a smoky mass and feeds it into the cabinet, where the preparation of smoked products takes place. The smoke interacts with the meat or fish and as a result of a chemical reaction, the products are transformed into tasty food.

The smoke generator body is filled with special wood chips, the consumption of which is equal to 100 g/h provided that smoking is done in a cold way. Then the air duct and compressor are connected to the body. Only after this can the fuel be ignited. It is worth noting that there are two types of smoke generators, namely with an upper and lower ejector.

Preparing for assembly

In order to assemble the smoke generator completely, required:

- Square pipe section 100×100 or round in diameter from 100 to 120 mmIt must be made of steel or stainless steel.

- Pipeline sections radius from 12 to 20 mmThe length can reach up to 40 cm. They will be used to create a smoke valve if we are talking about hot smoking.

- Plastic corrugated pipe length 2-3 mm, or better yet metal hose. Its diameter must correspond to the size of the external chimney.

- Compressor — a tee connection for pipelines. Its diameter must match the channel through which the smoke is supplied.

- Wires and switch.

- Thermometer.

Reference. All components can be purchased in the store and purchasing components for a smoke generator will not require any special expenses.

To fully assemble the smoke generator you will need: welding machine, grinder And minimum work experience with similar tools.

An inexperienced person may find the procedure of welding a chimney fitting to a pipe, making doors for a firebox and various covers difficult.

But if you have minimal skills in welding and using a grinder, then there will be no problems.

If you have no experience, it is better to resort to help of a specialistOtherwise, you can simply damage the smoke generator during assembly.

Manufacturing process, drawing

To make a working device you need adhere to the following sequence:

- It is necessary to make a caseFor this purpose, you can use a round or profiled pipe with a diameter from 100 to 120 mm. The wider the pipeline element, the more sawdust will fit in it. The length of the workpiece should be approximately 60 cm. When creating a large body, it is worth remembering that a large-sized unit will be more difficult to fill and move.

Photo 2. Drawing of a smoke generator for cold smoking. It is supposed to use a profiled pipe for manufacturing the device.

- Next step the compressor is being installed, the functions of which can be performed by a cooler removed from an old computer. With its help, the smoke will go to the right place, and the air circulation will occur faster.

- Necessary connect the smoke generator to the smoking chamber. This procedure requires special attention, since the installation has a rather complex algorithm.

Important! When connecting, you need to follow the instructions, which say that the smoke enters the smokehouse through a special pipeline. Do not forget that the latter must be cooled before use. To achieve this effect, you need to place the chimney in cold water or make the hose longer.

If the person assembling the smoke generator and connecting it to the smokehouse follows all the instructions, he can be sure that the device will work properly. If there is too little or too much smoke, It's worth checking the connections.

Photo 3. Drawing of a smoke generator for a smokehouse, the body of which is made from a fire extinguisher.

A cold smokehouse will perform its functions well if you connect a smoke generator to it correctly, as the quality of the food in the smokehouse depends on it. Incorrect assembly may affect the taste of meat or fish..

Reference. A regular fire extinguisher with a diameter of about can be used as a body. 100 mm and a length of 400-500 mm.

Difficulties in assembling a homemade smoke generator, choosing a compressor

The device of the described smoke generator is quite simple, but requires attention. During production, a person may encounter the problem of insufficient air supply. To optimize this process, the design can be connected pump, aquarium compressor, home fan or the computer cooler mentioned above.

As fuel for a smoke generator You cannot use wood that produces resin, since it can give the products the wrong smell and taste. It is also not recommended to use too small elements, but if there is no other choice, it is necessary to take care of a small chimney, the role of which can be played by an ordinary spring. It will allow the smoke masses to pass freely even through a layer of sawdust.

Don't forget about such an element of the smokehouse as ejector. If it is installed at the bottom of the combustion chamber, it will interfere natural influx of air masses.

Smokehouses designed in this way require constant monitoring. Otherwise, the products will spoil.

The above mentioned inconveniences can be eliminated by moving the ejector. to the top of the installationIf you take such measures, all the unpleasant aspects caused by poor quality work will most likely disappear.

How to properly connect a smoke generator with your own hands?

It is important to remember that an important point is smoke temperature in the smoke generator. It is on it that both the smell and taste, as well as the appearance of the finished smoked meats, depend. For adjustment purposes, you can increase or decrease the length of the pipeline. The longer it is, the lower the temperature will be.

It is necessary to make sure that tightness of the branch pipe, through which smoke enters. If a hole is found in it, it must be immediately patched and another hose must be used. Such malfunctions can lead to leakage of smoke masses and incomplete smoking, it will take much longer to cook the products, or it will not be possible to achieve the desired result at all.

Due to the simplicity of the design, any problem can be detected. If a person did the installation with his own hands, then he probably knows where he could have made a mistake. Evidence of an incorrect connection can be bad taste of food due to their presence in concentrated smoke.

Important! The smoke generator is regulated by the method trial and errorWhen the desired temperature is reached, the meat or fish will acquire an appetizing appearance and a pleasant taste and smell.

Is it difficult to make a smoke generator? Pros and cons of a homemade device

The described unit has both positive and negative sides.

If we talk about the advantages, then they include: ease of assembly and maintenance, efficient operation, absence of any financial costs for the creation of the structure and maintenance of the unit.

But the smoke generator also has negative sides. One of them is the need to keep the wood chips smoldering constantly. Smoke at a relatively low temperature is not able to quickly bring products to readiness. Meat and fish must be smoked for 2 daysThe only way to achieve readiness in less time is to increase the temperature.

Useful video

Watch the video to learn how to make a smoke generator for a smokehouse in one hour.

Comments

To control the temperature when installing a smoking unit, it is necessary to provide for the installation of at least one thermometer. And it is better to have two - one on the smoke supply pipe to the chamber, and the other in the smoking chamber.