What you need to know for effective installation of heating boiler automation

Boilers equipped with devices automatic control, They work independently, so the owners do not have to constantly take part in heating the house.

Maintaining a constant temperature and pressure in the coolant, regulating the intensity of energy or fuel consumption - all this happens automatically.

Content

Boiler automation devices

Reinforcement — an important part of the boiler equipment, its reliability is a guarantee of equipment safety.

Hydraulic arrows

Used to separate streams, allow you to organize independent circuits for the movement of the coolant.

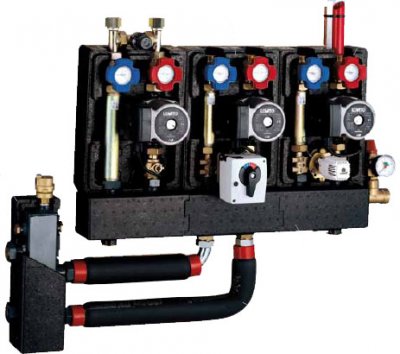

Rapid assembly group

Devices that allow you to connect the necessary add-ons to the boiler are connected to comb (distribution manifold).

The group is selected in accordance with the intended tasks: depending on them, the necessary components are introduced into the set.

The pump group includes:

- pump with suitable technical parameters;

- shut-off valves;

- fasteners;

- thermal insulation, meeting fire safety requirements.

All components of the group have factory certifications and are tested for leaks directly at the manufacturer’s plant.

Collectors

Designed to distribute liquid from the heating main along circuits and branches.

If a turnover is provided, then for collecting and mixing flows from contours and branches.

- They are more modern and convenient means for organizing heating communications.

- Increase efficiency indicators for any heating system.

- Indispensable for creating a microclimate in houses where two or more floors.

- Allows you to maintain temperature regime and other parameters for each branch separately.

Important! Correct selection of fittings extends the service life of the entire system as a whole and protects against accidents.

Types and functions of valves

Valves — are characterized as control and safety devices. With their help:

- are changing installations systems;

- is provided stability and support of specified parameters;

- becomes possible setting under specific conditions.

Three-way

Maintains a set temperature of the liquid at the outlet. Inside the device there is a washer made of a material that reacts to temperature changes.

When increasing or decreasing it changes size and changes the size of the outlet openings. The result is the timely addition of cold or hot water to the system.

Back

The purpose of this valve is to ensure unidirectional coolant flow.

Designed for high hydraulic resistance, it cannot always be used in systems with circulation without a pump.

For use in low resistance conditions, valves with sensitive damper, which responds to minimal pressure.

In the check valve, the adjustment is assigned to spring, which ensures the shutter is closed.

The valve is selected according to the parameters of a specific system; variants with different spring elasticity and different types of shut-off devices are available.

Regulating, shut-off and regulating, shut-off

Regulatory — change the intensity of water supply from maximum to minimum (for this, the valve opens or closes).

Shut-off — regulate the flow in two positions: only open or closed.

The installation is carried out in accordance with the direction of flow - it is indicated arrow.

Thermostatic

Automatically adjusts degree of heating of the radiator. When heated, the device's rod shuts off the coolant supply. Can be repaired — stock can be replaced.

Valves are selected depending on the location of the supply line to the radiator: lower, angular or axial.

Photo 1. Thermostatic valve model HP 30-65, brass, nickel-plated, external thread, manufacturer - "Stout".

Bottom-connected batteries are sometimes supplied with the batteries already installed. valve insertsRadiators with side connections are sold with special kits with valves included.

Pressure regulators

Protect heating from pressure surges. They are selected based on throughput capacity.

Bypass

They are triggered by a dangerous increase in pressure, for example as a result of a reduction in the water supply when the set temperature has been reached.

At this point the valve discharges into the return line excess boiling water.

As a result, the temperature becomes more uniform along the circuit, and the pump is protected from overload.

They are installed on jumpers and next to pumps.

Safety

Valves protect all parts of the system from excessive pressure, which happens when the coolant boils. They should be selected based on actual technical features - taking into account the excess tolerance in 20-30%.

Balancing

Similar to a valve, they are used as a limiter to regulate the intensity of the coolant flow, and support established parameters of pressure and flow rate of the coolant.

Often installed together with shut-off valves.

Flow regulators

They operate based on readings from ambient air and return temperature sensors.

Data can be obtained at places where radiators are installed, which allows you to get an even temperature in all rooms.

Prevents overheating of the environment.

Maximum pressure relay

Protects the system from overheating, explosion in case of a large pressure surge. The relay triggering results in automatic shutdown of the boiler.

Minimum pressure relay

The device is designed to protect against pressure drops. below the established minimum (set by the master). The minimum and maximum limits can be changed when setting up the boiler.

This membrane, which when triggered breaks the electrical connection. When the indicators return to normal, the membrane returns to its place and the boiler can be started again.

Thermostat

Holds temperature water within the user-specified boundaries.

Controller

Designed to implement sophisticated system management programs.

There are different types of controllers, however pressure and temperature sensors are provided in any of them.

The devices differ in the set of controlled objects and the means of communication with them and the entire heating system.

The operating principle of energy-dependent and energy-independent heating systems

All devices installed for the purpose of monitoring the system's work processes are divided into energy dependent (electronic) and non-volatile (mechanical).

Mechanical ones are cheaper, very simple in design and do not require electricity. The basic principle is changing the size or position of a structural element, sensitive to changes in temperature or pressure. Accordingly, the gas supply, the intensity of the coolant flow, and other operating parameters of the system are reduced or increased.

Energy-dependent automatic devices are controlled microprocessor, the valves are triggered based on data processing.

The operating modes of the system required by the user are set on the device display.

Reference! Electronic devices can be duplicated mechanical, then a breakdown in the electronics will not affect the operation of the heating device. This is especially true if there are long periods without power.

How to set up control yourself

Basic setup steps:

- Debugging of water supply systems, hot and cold. The safety manual is used as a guide, the safety valve and pressure regulator are checked.

-

The gas ramp on the burner of a gas boiler is checked. First, everything is checked without ignition, at minimum power, then at medium and at maximum.

If it works without failures, you can set the automatic mode.

- Pressure and temperature sensors are calibrated. The operation of the sensors is checked in two modes: emergency and automatic.

Then the system starts up. for 72 hoursIf it works without deviations, the setup can be considered successful.

If necessary, the automation can be reconfigured, for this you need wrench and screwdriver. The cover of the device is removed, changes are made to the range of acceptable values (when the device is triggered), the pressure increases or decreases.

If the pressure changes after connecting the device to the network, the new values will be displayed on the pressure gauge.

It is better to regulate the temperature in the premises directly on site by installing sensorsThe degree of heating of the coolant can be adjusted on the boiler.

To properly adjust the temperature in the rooms, a thermostat, which provides programming capabilities with a cycle of up to a week and control the boiler via a mobile phone through a special application.

Important! It is better to entrust the installation of automatic devices for professionals, especially when gas boiler. If you have the knowledge and skills, you can set it up yourself.

Features of automation for electric boilers

Many of the automatics for gas boilers are perfectly suitable for electric ones. In addition, electric boilers are well compatible with automatic control devices, so craftsmen can create a completely modern one with their own hands. Automatic heating device for home.

Peculiarities:

-

The responsibility for protecting the boiler from excess pressure lies with blast valve, which is triggered by a pressure surge and discharges excess coolant into the sewer.

This mechanical device should be installed as a spare even if electronic devices are installed.

- To assess the actual condition and quality of the boiler, it is necessary pressure and temperature sensors.

- The boiler can be switched on and off mechanical automation. For example, plate-type thermostats that are installed indoors. The device will close or open an electrical circuit in accordance with the increase or decrease in temperature in the room.

The safety of the system is ensured by sensors that protect against voltage surges.

Additional energy savings are achieved by installing blocks for mixing cooled and heated water in pipesEquipped with this minimum of automatic devices, the boiler will heat the house perfectly.

Solid fuel devices

Electronic equipment for automated control allows increasing the boiler output and saves fuel resources. It is important to select automatic devices based on the technical data of the heater.

The automation consists of computer and fan turbine. Thanks to his work in the boiler:

- supported constant temperature;

- the fuel burns efficiently, which will allow more economical to spend it;

- The sensors allow you to clearly control the temperature in different sections of the boiler and evenly distribute heat throughout the entire circuit.

Installation of automatic devices is entrusted to professionals. You can calibrate them yourself, according to the instructions.

Mechanical automation much cheaper, than electronic. Simple device and simple functions: open and close air access to the combustion chamber. Energy independent, therefore more reliable. Easy to install with your own hands.

Automation for a solid fuel boiler makes fuel consumption optimal: this is a significant saving.

Reference! The use of control devices has helped this type of heating installations become popular - automation can be installed for almost any boiler, which turns into a modern device.

What exactly is improved in a solid fuel boiler:

- adjustment temperatures, easy setup;

- control of air supply to the furnace: when cooling, more air is supplied, when overheating, less;

- the unit can be left unattended, the house maintains a normal temperature;

- Security system is in progresst signal of malfunction or failure;

- in case of power outage, the devices are equipped with a possibility of autonomous operation;

- in many models the fuel is loaded without human intervention;

- there are devices that regulate ash removal;

- the boiler can be controlled from remote control.

Useful video

Check out the video to learn more about the weather-dependent automatic control system.

Automatic control - safe and reliable!

Boilers with automatic control are not inferior to gas and even electric models. It can be installed even on a simple device already in use. However, each automatic device should be selected very carefully, checking its compatibility.

A boiler without automation requires a fairly responsible attitude from the owner, a lot of attention and is an unsafe device.

The automation brings the heating devices to safety standard — correctly selected and installed devices ensure stable operation, uniform heating and a guarantee of peace and warmth in the home of their owner.