Five simple tips: how to choose an expansion tank for heating and not cause an accident

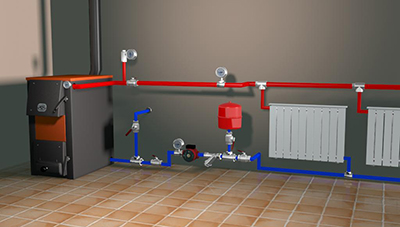

One of the most important components of the heating system is the expansion tank. This is air or gas tank, maintaining the required pressure in the circuit.

If the tank parameters do not meet the requirements, functionality and durability the heating system will tend to zero.

Content

Why do you need an expansion tank for your heating system?

The expansion tank is used for the purpose of ensuring uninterrupted operation of heating system devices and protection from accidents.

The main purpose of the tank is compensation for lack of volume heating circuit.

When heated, the liquid increases in volume, the pressure inside the pipeline increases and the excess liquid is forced out into the expansion vessel. When the pressure decreases, the water returns to the pipes.

Types of Expansomats: What They Are and How to Choose the Right One

Exists two types expansions:

- open;

- closed membrane.

Open

Open - a cylindrical container with a pipeline connected to it. It is mounted at the highest point of the heating circuit - under the ceiling, on the roof or in the attic. The cover is needed to prevent external debris from entering the system; it has no other functions.

The water in this type of tank evaporates and periodically requires topping up. If access is difficult, a automated liquid level control. Additional pipes with a shut-off valve for water are supplied, as well as a branch pipe for draining excess liquid in case of overflow. The overflow hose is led out into the sewer or simply outside through the wall.

Photo 1. The open-type cylindrical expansion vessel is easy to install and operate, and is economical.

Pros - easy installation and maintenance, independence from the electrical network, low cost of construction. Having the necessary skills, you can make it yourself from steel sheets.

Cons — rarely fits into the design when installed indoors; requires mandatory insulation if installed outside; accelerates the corrosion process of the pipeline (from constant contact of water with air); not suitable for heating with an electric boiler.

Reference! The location of the tank in the system should be convenient for its maintenance. When installing a homemade structure the probability of incorrect joining of the pipes increases significantly. The tank is attached only after the installation of the circuit is completed.

Closed

A closed expansion vessel (membrane) is a sealed container with an elastic membrane gasket inside, which divides the tank into two parts — a hydraulic chamber and a pneumatic chamber. Pressure stabilization to the required level occurs due to a change in the location of the membrane in the tank.

Photo 2. A closed expansion vessel in the form of a hermetically sealed container, divided inside by a membrane into two parts.

When the liquid in the heating system is heated, the excess coolant enters the hydraulic chamber. Under the influence of pressure, the partition reduces the size of the pneumatic chamber. The gas contained in it is compressed and presses on the hydraulic chamber. This occurs pressure compensation in two sections, and the complex again acquires equilibrium. When the pressure of the liquid in the pipeline decreases, the opposite processes occur.

The expansion valve must be installed on the return line of the pipeline for optimal operation of the pumping equipment system. Location pump - between the boiler and the tank.

Types of membrane

The membrane happens two types:

- Balloon — a replaceable element, which is an undeniable advantage. Most often it is made of technological rubber. When cracks appear, the flange fastening of the partition makes replacement simple and quick. This significantly reduces the cost of repairing the structure.

- Diaphragm — a non-removable partition capable of stabilizing small pressure drops in the pipeline. It is made of elastic polymer or thin metal. If a membrane of this type fails, the entire expansion vessel must be replaced.

Advantages of closed tanks — when emergency overloads occur, the membrane ruptures, maintaining integrity expensive technical design.

Insulation of the coolant from atmospheric flows increases the service life of the heating circuit; pipes of smaller diameter are used, which makes it cheaper design.

Protection of elements Heating is carried out by equipping it with safety valves.

Cons — large dimensions in large areas, increased requirements for the design.

Attention! During the operation of the complex, the mass of the membrane increases, therefore The mounting location must be load-bearing. Where the tank is connected, it is necessary to install a safety group with a pressure gauge that monitors pressure drops in the tank.

Which tank to choose? Five main recommendations

It is recommended to take into account:

- For which system you need to choose a tank. For open - you should buy or make an open-type container for closed - closed membrane.

- The amount of coolant, boiler capacity and pipeline length — based on these values, the required container size is calculated.

- Membrane selection in closed tanks by elasticity; possibility of replacement.

- What material is it made of? the tank body and the partition itself.

- Temperature range of use, the ratio of sanitary and hygienic standards, operating conditions.

The main materials for the tank membrane are: EDPM (propylene elastic rubber/synthetic ethylene) and natural butyl rubber.

Selecting a formula for calculating volume

The easiest method of calculation is to determine the amount of coolant in the circuit. The volume of the expansion tank is 10-15% of the volume the entire heating complex.

Formula for calculation:

V=E*C*(Pmax+1):(Pmax+Pmin),

Where V — calculated volume of the container; E — coefficient of expansion of liquid (for water) 0.04 or 0.05, for antifreezes 0.1—0.13); WITH — volume of the heating system; Pmax — maximum boiler pressure (indicated in the passport); Pmin — initial pressure of the expansion tank (indicated in the documentation).

Important! Insufficient tank size is a common cause unstable work heating complex.

Useful video

The video provides recommendations to help you choose an expansion tank for your heating system.

The right choice is a guarantee of reliability and trouble-free design

The reliability and safety of autonomous heating in a private home depends entirely on the correct choice of the elements it consists of. For houses with small area The open type (without pump) is often used. For large buildings - closed type (with circulation pump). Vertical or horizontal installation depends on the approximate installation location.

It is mandatory to check the selected membrane for compliance with quality and safety requirements.

The attached documents must contain: manufacturer's instructions for installation and operation, information on passed factory tests, certificate of conformity, service coupon (warranty).

The manufacturer's technical documentation specifies restrictions on use — permissible pressure values, requirements for the composition and properties of the coolant, the range of temperatures used. The materials used to manufacture the flange, expansion tank body, membrane, as well as the type of part (replaceable or permanent) and dimensions must be specified.

The performance characteristics are checked with the complex switched off., drained coolant and zero boiler pressure values. It is better to entrust the test run of the circuit with an expansion tank to a professional who will give competent advice on the features of use and further trouble-free operation.

Comments