Availability in operation and reliability: characteristics of a closed-type expansion tank for heating

An expansion tank is a mandatory heating element.

This equipment is intended to regulate the pressure in the system, thanks to its special property - the ability to absorb excess water volume, which is formed by the expansion of the coolant when it is heated.

At the same time, the pipelines are not subjected to excessive pressure with the resulting depressurization and, accordingly, serve without interruption for many years.

Closed type expansion membrane tank

Taking into account the functional features of the expansion tank, we can distinguish two types of construction, by which the above-described devices are distinguished:

- Open, the main disadvantage of which is the need to insulate the device.

Otherwise, such equipment, often installed on the roof, simply freezes along with the pipe connecting it, which can lead to an explosion of the entire heating system.

- Closed, which is a more modern version of the tank.

Operating principle

When the container is not full the elastic membrane occupies a small part volume, as opposed to air, which occupies the remaining share. After the water has heated up sufficiently, it enters the gap between the membrane and the body, remaining there until it cools down. After the temperature drops, the volume of the coolant also decreases, which then is squeezed back into the system compressed air tank.

Description of the device

The expansion tank has sealed metal case and an internal rubber membrane. It divides the tank into two parts — an air chamber filled with gas (nitrogen) and a water chamber for the incoming coolant.

Photo 1. Cash Acme expansion tank with a rubber membrane inside, dividing the device into two parts.

There is one below hole in order to connect the tank to the general system, and at the top of the body there is a nipple, which serves to regulate air pressure.

Reference! To compensate for the expansion of the coolant during heating, you can use an ethylene glycol mixture with a value of concentration maximum 50%.

Volume

An incorrectly selected expansion tank volume can lead to problems when operating the heating system. In a tank that is too small, the expansion tank will often trip. safety valve, releasing the coolant to the outside, and an excessively large volume will cause unnecessary financial costs and the inappropriate seizure of free space.

Appearance

Expansion tanks can be two types installations:

- horizontal;

- vertical.

Typically, their body has a capsule-like or flat shape with a volume of from 1 to 10,000 liters with the possibility of additional fastening.

Advantages:

- safety, including water purity;

- low operating costs;

- easy installation and the ability to install in any part of the house;

- reliability and ease of use;

- preventing liquid from overflowing from the tank;

- operation in any type of water;

- heat preservation without loss;

- minimal air flow;

- natural rubber membrane, which is also permitted for drinking water supply;

- tank durability, due to the absence of direct contact with water and air.

Flaws:

- breach of joint tightness may lead to air entering the heating system;

- the difficulty of placing large volume tanks;

- need for additional fastening.

Where is it installed and how to choose a location?

The expansion tank can be installed anywhere in the heating system. The main thing is its availability.

However, it would be preferable connecting the device to the return pipeline (return), since it is there that the load on the membrane is minimal due to the reduced temperature of the coolant.

How to install correctly?

When installing an expansion tank, there are several simple recommendations, the implementation of which contributes to the reliability of the work process:

- maintaining tightness: the container cannot be disassembled - the tank is simply connected to the pipeline located near the boiler;

- installation of safety devices to prevent pressure increase;

- connecting the tank to the branch;

- maintaining a stable positive temperature;

- mounting equipment on a load-bearing wall;

- installation of a device with a volume of more than 30 liters on the floor;

- installation of a pressure gauge at the tank outlet;

- connecting a check valve at the tank inlet in the absence of a pump.

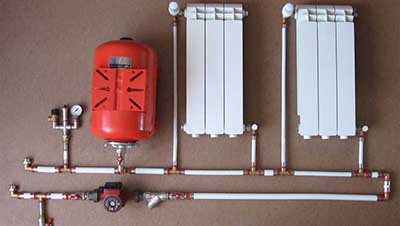

Photo 2. A red expansion tank with a capacity of less than 30 liters is mounted to a load-bearing wall.

How to choose a tank for a heating system?

For normal functioning of the heating system, it is necessary to select an expansion tank that corresponds to all parameters.

Important! Devices intended for heating - red, and for water supply - blue.

Parameters by which you can select a design:

- Volume. The selection of the expansion unit is carried out taking into account the total volume of coolant for the heating system.

If the coolant is water, then the volume of the tank should be equal to 10% from its size, and when used antifreeze — 15%.

For example, For 100 liters of water you need a 10-liter tank, and for 100 liters of antifreeze you need a 15-liter tank.

Attention! The first indicator of an incorrectly selected device or its incorrect settings is constant operation safety valve.

- The choice of the tank is made, taking into account the features of the heating system with a solid fuel boiler. When it is operating, control over the selected temperature is difficult and the coolant can easily exceed the set mode.

In such a process, there is a sharp increase in the volume of the coolant, for which an expansion tank with a reserve is needed. Therefore, the standard calculation of the tank indicator multiplied by 2.

- Membrane. It can be replaceable (flanged) or non-replaceable.

Advantages of flange membrane:

- possibility of replacement through the flange in case of mechanical damage;

- units with such a membrane are of two types - horizontal and vertical, which significantly saves space;

- flange membrane withstands more pressure than a non-replaceable one.

The advantage of a non-replaceable membrane is economy, thanks to the rigid fastening around the perimeter of the tank.

- Material. The choice of the tank should be based on high-quality materials of two main components:

- Membranes. Main characteristics: operating temperature range, service life, hygienic and sanitary requirements, dynamism and resistance to high temperatures.

- Corps, which requires durable and reliable metal, such as high-quality carbon steel with powder coating, for long-term operation.

- Label. It should contain a brief technical specification of the expansion tank, indicating the maximum allowable pressure, temperature range, membrane type and tank model with serial number.

- Manufacturers. Italy and Germany are considered the leaders in the production of expansion devices.

However, many models are presented on the market by domestic manufacturers, which has a positive effect on pricing policy with consistently good quality and simple operating principle.

- Approximate cost. Depending on the country of manufacture and volume, the price of the expansion tank will vary within the range $20 for a 5-liter tank and $265 for a 300-liter tank.

Homemade design

Suitable device is allowed make it yourself, following a few tips:

- A homemade tank can be welded made of 2.5 mm sheet steel. Alternatively, a metal container from under paint or varnish will do, provided that the thickness of the walls is observed. The ideal alternative is a stainless steel tank from an old washing machine for 10-15 liters (but not less than the established standards).

- When using ready-made containers, it is necessary clear it of any remaining flammable materials by evaporation.

Photo 3. Homemade expansion tank for a closed-type heating system, made from stainless steel sheets.

- Paint the equipment - inside with waterproof paint, and outside with enamel for anti-corrosion protection.

- After the body has dried, weld the fittings to connect the device to the heating system pipes at a height 5–11 cm from the bottom.

- Cut a top hatch with bolt fastening for internal cleaning of the unit.

- Make a sealed hole with a steel fitting welded to it for checking the water level with a probe (a metal rod with divisions).

- Cut a thread on the fitting and make a lid with a rubber seal to close the hole.

- Connect the tank to the main line.

Useful video

The video explains where it is best to install the expansion tank and gives some tips on its installation.

Maintenance and operational safety

Expansion tank - important element heating system, which requires:

- maintenance — check every six months for mechanical damage, adequate pressure and membrane integrity;

- compliance with safety precautions - connect to the system with the help of specialists, do not exceed the permissible loads, perform dismantling with the system disconnected and drained of water and do not change the factory design.

Following simple rules will ensure full and long-term operation of the expansion tank.