A massive but durable device: is it worth installing a wood-fired boiler for your home?

Wood boiler - heat generating plant, designed to heat the coolant in an autonomous heating system by means of burning wood or wood waste.

Can be fired with coal and other fuels with a higher combustion temperature if the firebox walls are thick enough and made of heat-resistant steel.

Some may think that this method of heating is outdated and not suitable for a modern cottage. But it is too early to send wood boilers to the dustbin of history: this equipment is not only still in demand, but also constantly improving. Read on to find out what they are like and what the buyer should pay attention to.

Content

Requirements for wood boilers for private wooden houses

A boiler that runs on wood or other solid fuel must have the following qualities:

- Economy. In other words, the heat generator has as much as possible higher efficiency.

- Ability to last longer work on one fuel load. A very important criterion, since the work of any wood boiler cannot be done without the participation of the user. The less often he has to add wood, the better.

- ReliabilityA boiler breakdown in the middle of a frosty weather is a serious incident that is dangerous not only because the home will cool down, but also because the heating system elements will rupture due to frozen coolant. The simpler there will be a boiler design, the lower the probability of its failure.

- Availability of automation. It is good if the boiler itself can regulate the combustion mode and thus maintain the coolant temperature within the limits set by the user. The most ideal option is if the fuel is loaded into the firebox automatically.

- Energy independence. This quality may be needed if there is no electricity supplied to the house or it is often disconnected. Note that this point does not contradict the previous one: today many companies produce reliable energy-independent automation, the operation of which is based on the ability of various materials to change their dimensions when heated or cooled.

- Lack of inertia. In other words, the design of a wood boiler must provide the ability to quickly change the heat output.

- Durability.

Varieties

To date, it has been developed several designs wood-fired boilers.

Direct combustion boiler

This heater is also called classic. It has the most simple design: the body contains firebox and heat exchanger or water jacketThe intensity of fuel combustion is regulated by the air damper. Advantages This solution has the following:

- simplicity constructions, and therefore reliability;

- the boiler can be non-volatile;

- compact dimensions;

- unpretentiousness to the quality of fuel.

Flaws boilers:

- fuel has to be added to the firebox every 4 hours;

- there is no possibility quickly reduce power heat generation: even with the valve completely closed, the fuel continues to burn for some time;

- low efficiency.

With top combustion

This type of heater was created with the aim of extending the operating time on one load of combustible material in order to reduce user involvement. The idea is as follows: fuel is loaded into high cylindrical firebox in the form of a column and is ignited from above, while air is supplied strictly to the combustion zone (as the fuel burns out, it gradually moves down).

Top-fired coal boilers can operate on one load of fuel up to several days.

Important! Boilers with top combustion impossible to finish loading fuel until the current batch burns out. In addition, the remaining fuel often sticks to the walls and those have to clean.

Wood boilers of this type can be non-volatile, coal - for complete combustion of coal they need forced air supply.

With controlled air supply

Boilers are also designed to extend the operating time on one fuel load, but they operate on a different principle. It consists of the following: when the coolant is sufficiently heated, the automatic system closes the valve, and the flame in the firebox goes out. When the coolant cools down, the fan turns on and fans the flame in the firebox.

Photo 1. Solid fuel heating boiler with controlled air supply "Sibir-Gefest", capacity 30 kW.

Such boilers are considered more practical, than heaters with top combustion, but they cannot be energy independent.

Pyrolysis boilers

A slightly different principle of fuel combustion is used: it heated in a separate chamber to a high temperature, causing the biopolymer molecules to decompose into flammable gaseous substances; this the gas mixture (wood gas) enters another chamber and is burned there.

The pyrolysis boiler has a number of advantages:

- The efficiency is very high, since the fuel burns almost completely;

- compared to other wood boilers, exhaust contains the least amount of harmful substances;

- long term work on one tab;

- are controlled almost the same easily, like gas boilers;

- ash is formed in in small quantities.

Flaws:

- required electricity;

- you can pawn only dry firewood (humidity no more than 20%).

Heaters with top combustion and controlled air supply are called by the general term "boilers" long burning" Later, pyrolysis boilers began to be included in this group.

Pellet devices

The only option for a solid fuel boiler in which fuel can be loaded automaticallyIt has the form of uniformly sized granules (called pellets), which are obtained by pressing sawdust or husks of agricultural crops.

Another important advantage: the auger feeds fuel in small portions (a special pellet burner is used), so inertia the pellet boiler is completely absent.

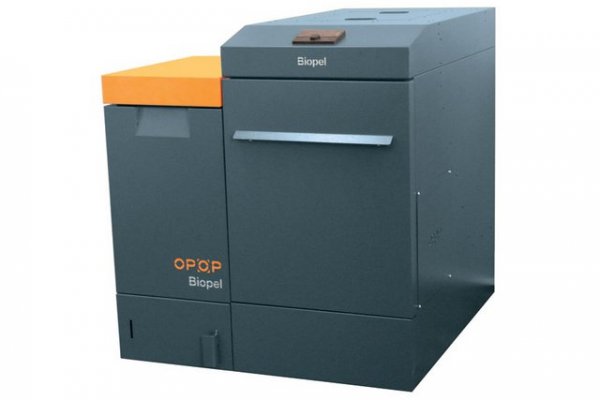

Photo 2. Pellet boiler of the BIOPEL series, 228 kg, power 30 kW, manufacturer "OPOP".

Advantages and disadvantages of wood boilers

To summarize, wood boilers good next:

- They are absolutely autonomous, especially energy-independent models.

- The fuel is more expensive than natural gas cheaper and is safer.

- For installation no need to get permission any services, and there will also be no need to install any extra communications.

Now about disadvantages:

- Wood boilers have significant weight. Especially long-burning heaters, the firebox of which is of increased size.

- Regardless of the design, user participation required. Even the owner of a pellet boiler will have to fill the bunker with pellets every 5-7 days.

- The exhaust contains a lot of soot, so the chimney often has to be cleaned.

- Due to the large amount of acid-forming oxides in the exhaust the condensate turns out to be very aggressive, which negatively affects the service life of the chimney. This is especially true for coal boilers.

- Required fuel storage space.

- Due to inertia it is used complex harness (recommended even for pellet boilers). The difficulty lies in the design of the mixing unit, through which the hot medium from the feed is fed into the return line, if it is too cold.

What to look for when choosing

When choosing boilers, you need to pay attention to the following:

-

Heater power must correspond to the heat loss of the cottage during the coldest period of the year (determined by a special calculation).

It is believed that with good insulation for every 10 sq. m of heated area required 1 kW of heat.

-

Firebox walls must be made of heat-resistant steel and have sufficient thickness.

This is especially true for coal boilers, since the combustion temperature of coal is significantly higher than that of firewood. The fireboxes of such boilers must be made of sheets at least in 3 mm, or better yet in 5 mm.

- Necessary check pressure, for which the heat exchanger of the device is designed. The most durable ones hold 3 atm.

- If the boiler is equipped with forced air supply, it is desirable that the fan is not located too low - it will pull dust from the floor.

- If the heating system is not equipped with a circulation pump, you need to choose a unit that can operate in the mode natural circulation.

Useful video

Watch the video to learn what to look for when buying a boiler for your home.

Conclusion: independence and low operating costs

So, modern wood boilers are an excellent alternative to gas. It is important not to fall for the tricks of unscrupulous sellers who pass off classic heaters as long-burning devices. It is not difficult to distinguish them: a “long-burning” boiler at least has an enlarged firebox. volume 80 - 120 l.

You should also be careful with devices that are intended for use in smoldering mode. They also work on one load of fuel longer than usual, but have very low efficiency and a whole host of other disadvantages.

Comments