2 in 1: heat and hot water for your home. How to choose a double-circuit gas boiler?

You are viewing the section Double-circuit, located in the large section Gas.

Among heat generators that run on gas, gas boilers are the most common. They are distinguished by their low fuel cost, high efficiency.

In addition to technical characteristics, such devices are classified by the number of connected circuits.

Single-circuit boilers are used only for heating, the use of double-circuit analogs in addition to heating allows for hot water supply (hereinafter referred to as DHW) of an autonomous type in heated premises.

Content

The structure and operating features of a double-circuit gas boiler

The main difference The difference between double-circuit boilers and single-circuit analogs is the ability to heat not only the coolant, but also ordinary water for sanitary needs.

In addition to the design, dimensions and technical features for each model are characterized by differences in design, while their general structure is approximately the same.

Any double-circuit boiler includes a combustion chamber with a burner, a heat exchanger, and electronic elements that regulate the operation of the unit in automatic mode.

Functioning double-circuit gas boiler is carried out according to the following scheme:

- An air-gas mixture is fed into the combustion chamber of the boiler. When it burns, heat energy is released. Depending on the specific model, the combustion products are either discharged through the chimney or liquefied to a condensate state, after which they are disposed of manually.

- The heat generated by burning gas is transferred to the coolant through a heat exchanger, circulating in a closed heating circuit - from the boiler to the radiators located in the heated rooms and back.

- When you open a hot water tap (in the bathroom or kitchen), the generated thermal energy is used to heat the sanitary water., used for domestic needs. In this case, in models not equipped with a storage tank, the heating process is suspended during the operation of the DHW circuit, and resumes when the hot water tap is closed.

Main modifications

Models of double-circuit gas boilers differ depending on a number of design solutions and their combinations.

The principle of heating water

Double-circuit gas boilers are divided into flow and storage modelsWater heating in flow-through devices is carried out in real time – directly when the hot water tap is opened.

Photo 1. Double-circuit storage gas boiler of blue color with a boiler, the water in it is heated in advance.

Storage boilers are equipped with built-in boilers with a volume of from 30 to 100 liters, in which the water is preheated.

Important! When the accumulated hot water supply is running out, further operation of the DHW circuit in the storage boiler is carried out on a flow-through principle, until the hot tap is closed, after which the built-in boiler is filled again.

Heat exchanger type

Modern double-circuit gas boilers are equipped with duothermic or bithermic heat exchangers. Duothermal element is a tandem of two heat exchangers responsible for individual functions – heating and hot water supply.

Bithermal heat exchanger works both for heating the coolant and for hot water supply - depending on whether the corresponding tap is open. In most cases, it is optimal to use a boiler equipped with a duothermic plate heat exchanger.

Convection and condensing boilers

In convection (traditional) models, combustion products are disposed of through the chimney, while some of the generated thermal energy is lost.

In condensing analogs, the temperature of combustion products decreases to the “dew point”, after which by-products change from a gaseous to a liquid state.

In this case, an additional heat exchanger captures the thermal energy released when the aggregate state of the exhaust gases changes.

Convection boilers cheaper, but for condensation analogues it is typical higher efficiency.

Important! When using condensing boilers in heating systems equipped with old-style cast iron radiators, the heating efficiency is significantly reduced.

Combustion chamber type

For any boiler to operate, a constant supply of air is required, as well as the removal of combustion products.

In models equipped with open combustion chambers, the principle of natural draft is implemented: air for operation is taken directly from the room in which the boiler is installed, and exhaust gases are discharged through a traditional vertical chimney. Installation of such structures is allowed only in separate, specially equipped rooms.

In units with a closed combustion chamber The principle of forced draft is implemented - air circulation is carried out through a coaxial chimney, which is discharged to the street through the wall. The built-in turbine forces outside air into the combustion chamber. The combustion products are discharged to the outside in a similar manner.

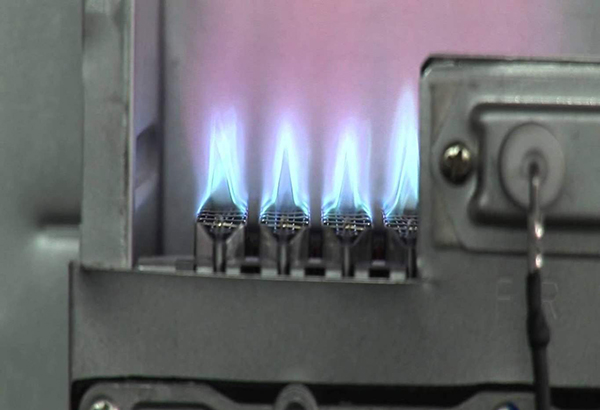

Photo 2. Closed-type combustion chamber with forced draft, air circulation in it occurs through a coaxial chimney.

To install these units, it is not necessary to allocate a boiler room, but there are a number of legislatively established requirements for premises that allow the installation of such devices. In addition, boilers with a closed combustion chamber are energy-dependent - for their operation it is necessary permanent connection to the power grid.

Installation method

According to this characteristic, dual-circuit ones are divided into: wall and floor models. The first ones are attached directly to the wall, while the floor-standing ones are installed on the floor or on a pre-prepared base.

Wall-mounted boilers are more compact, however, they have less power compared to floor-mounted counterparts – effective heating is only possible for rooms with an area of no more than 200 m2, and the average heating rate hot water supply – 14 liters per minuteIn addition, the service life of wall-mounted models is shorter compared to floor-mounted options.

Important! In addition to the above modifications, double-circuit gas boilers differ in the type of burner (regular or modulated) and ignition method (manual or automatic).

Advantages and disadvantages of a 2-circuit device

Besides the obvious ones advantages use of gas boilers (such as low gas price and high efficiency), for 2-contour models are also characterized by:

- Compactness. Regardless of whether a wall-mounted or floor-standing modification is used, the dimensions of a double-circuit boiler are smaller compared to the dimensions of separate boiler and water heater designs.

- High level of automation. Double-circuit boilers are automated, which allows significantly reduce risks, typical for the use of household gas equipment. In addition, automation makes the device convenient to use.

- Relatively low priceThe cost of purchasing and installing a double-circuit boiler is lower compared to the cost of purchasing a boiler, a separate water heater and installing them into the heating system.

- Difficulty of self-assembly of such a unit is significantly lower, especially when compared with separate installation and adjustment of the boiler and water heater.

- Autonomy of hot water supply. This feature allows the use of dual-circuit units. all year round: during the heating season, the boiler provides heating and hot water supply, in the warm season - only hot water supply. In this case, the building or premises equipped with such a unit does not depend on the operation of the centralized hot water supply channel.

- Reduction of utility billsWhen using a double-circuit boiler, the level of utility costs is reduced, since there is no need to pay for centralized hot water supply.

Important! Installation of additional equipment (primarily – thermostat) increases convenience and comfort when using a double-circuit gas boiler.

Among the main ones disadvantages Two-circuit models are distinguished:

- Limitation to one water intake pointIf there is a second point, its intended use will require the installation of an additional heat generator.

- Increased water heating time. When you open the corresponding tap, you have to wait for some time before the water heats up. However, this drawback is more inherent only for flow-through models.

- Number of users. The efficiency of a double-circuit boiler decreases with an increase in the number of users. The limit for an average unit is no more than three people.

- Short service life. Functioning models flow type decreases in conditions of increased water hardness.

Useful video

A video review of one of the models of a double-circuit gas boiler, which tells about the principle of its operation and characteristics.

Justification for acquisition and use

Intended use A double-circuit gas boiler is allowed for both individual rooms and buildings.

However, the efficiency of such a device depends on a number of factors:

- modifications and characteristics the unit used;

- area of premises and the number of regular users;

- thermal insulation and natural heat loss indicators heated real estate property.

Regardless of these factors, the use of double-circuit boilers is justified in rooms and buildings that are not connected to the centralized DHW circuit or that experience constant difficulties with shutdowns and/or interruptions in the supply of hot water.

Comments