Fuel consumption is minimal! Gas boiler with a closed combustion chamber

Method of heating with gas in a closed combustion chamber is realized by burning fuel in an insulated boiler body. Air supply and combustion products removal are carried out from the outside, from behind the outer wall of the building.

The boilers were named turbocharged, since the air flow is forced by turbines – fans.

Content

The structure and operating principle of gas boilers with a closed combustion chamber

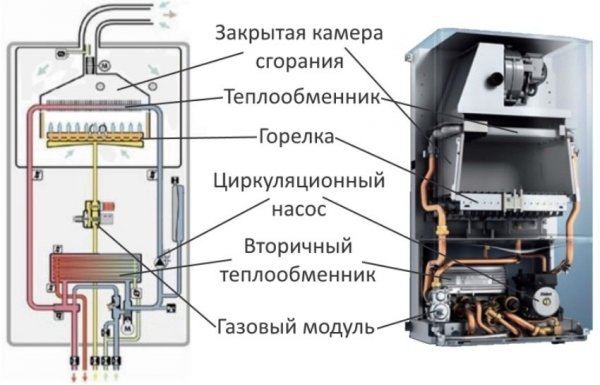

Design gas boiler includes a housing with forced-draft burners and a heat exchanger located inside, and a coaxial pipe through which air is supplied and combustion waste is removed.

Photo 1. Internal structure and diagram of a gas boiler with a closed combustion chamber. The arrows indicate the parts of the device.

In a closed boiler chamber, as opposed to an open one, forced draft is provided by means of a smoke exhaust fan. The camera has an outlet outside the building via a coaxial pipe, which consists of two pipes placed one inside the other. Air from the outside is sucked in through the outer pipe, participates in the combustion process, and the exhaust gas is discharged through the inner pipe.

Due to the fact that the draft in the gas boiler is forced, the need for a vertical chimney is eliminated, the outlet pipe is mounted into the nearest wall in a horizontal, vertical or inclined position.

Gas combustion is provided by means of forced draft burners. They differ from conventional atmospheric ones by a more complex device, including a fan that pumps air supplied in portions. The power of the gas burner is regulated together with the change in the rotation speed of the fans. Taking into account the pressure in the main gas pipeline the optimal ratio of gas and air mixture is achieved, due to which combustion parameters are improved and gas consumption is reduced.

The energy from the burnt fuel is transferred to the coolant through the boiler heat exchanger, which can be made made of cast iron, copper or steel. Cast iron heat exchangers have the best characteristics. Cast iron resistant to corrosion and thermal stress, and also has the best thermal characteristics, lasts longer.

Copper It is also not subject to corrosion, heats up and cools down quickly, and is more often used in imported models.

Heat exchangers made of steel, presented mainly by domestic manufacturers, are easy to manufacture and inexpensive. However, steel rusts, so the service life of steel products is short.

Turbocharged gas boilers operate automatically. Thus, control and safety issues are solved.

Optimal operating parameters are set using sensors boiler systems: ignition mode, gas burner operating power, volumes of water for circulation in the heating system are determined. The boiler safety system includes protection in the event of burner flame failure, insufficient fuel consumption, problems with exhaust gas removal, unit overheating, etc.

Boilers can be equipped with different waste treatment methods. In convection models In gas boilers, combustion products include hot water vapor, which is released into the atmosphere with the exhaust gases. In capacitors boilers have an additional heat exchanger for cooling water vapor. When passing through this heat exchanger, additional heat is released, which increases the overall efficiency of the device. Some of the combustion products dissolve in water and are discharged into the sewer.

Main types of gas boilers

The power of the boilers affects their size and weight., and the functionality are related to the number of contours. Lightweight low-power boilers for small residential and utility rooms are implemented in a wall-mounted design. Both light wall-mounted and heavy floor-standing boilers can solve problems not only of heating, but also of hot water supply (DHW).

By placement: wall and floor

The most powerful ones are floor standing boilers. For a standard-sized residential space, their capacity is excessive. Large floor-standing boilers are more often used in production or for heating houses that have minimum two floors.

Photo 2. Floor-standing gas boiler with a closed combustion chamber. The chimney is located in the upper part of the device.

Floor-standing boiler models are more reliable and their service life is longer. on average 5 years more, than wall-mounted ones.

The design of compact, low-power, lightweight boiler models allows them to be hanging on the walls of the room.

By the number of circuits: single-circuit and double-circuit

Single-circuit the boilers only work for heating, dual-circuit — for heating and hot water supply. Both single-circuit and double-circuit boilers can be wall-mounted or floor-standing.

A two-circuit solution can be in the form of:

- separate contours;

- bithermal heat exchanger.

The boiler's bithermal heat exchanger is performed in the form of a serpentine with a pipe-in-pipe combination. The main heating pipe contains a hot water supply pipe. Water flows in these circuits in opposite directions. Heat exchangers of this type are sensitive to water quality. If the water in the service area is hard, scale accumulates and the unit fails.

Attention! For double-circuit boilers There are restrictions on the supply of hot water. The boiler should be installed near the water intake points, and they should also be located close to each other, that is, the bathroom should be located next to the kitchen.

If the points are spread over a large distance, the heating will be ineffective. In addition, low-power boilers are serviced at the same time only one water intake point.

Photo 3. Wall-mounted double-circuit gas boiler with a closed combustion chamber. Heating and hot water supply pipes are connected to the device.

You can get hot water from a single-circuit boiler by connecting it indirect heating boiler. Almost all modern boilers have this capability, however, the piping will require significant material costs.

Reference. Wall-mounted boilers can heat an area up to 400 sq.. m. Dimensions by height up to 70-75 cm, length 30-31 cm and width - 40 cm. Temperature of water in the DHW system up to 55-60 °C.

Floor standing boilers heat up to 1 thousand sq. m. Height dimensions up to 100 cm, length up to 45 cm, width up to 60 cm. Water for hot water supply is heated up to 80-90 °C.

Advantages

Gas boilers with a closed combustion chamber have many advantages.

Eco-friendliness

Closed type gas boiler does not consume air from the room. This is especially important in the cold season, when ventilation is difficult. At the same time, gas combustion products also do not enter the room. If an additional condenser heat exchanger is implemented in the gas boiler model, then Atmospheric pollution is reduced to a minimum.

Minimum gas consumption

The efficiency of turbocharged and conventional atmospheric gas boilers is approximately the same, however, Gas consumption in closed boilers is more economical.

Depending on the pressure in the main gas pipeline, the rotation speed of the turbine in the forced-draft burner is automatically adjusted.

Thus the optimal gas-oxygen ratio in the air mixture is selected, as a result of which the mixture is completely burned and releases the maximum amount of heat.

No chimney needed

An important condition for the good operation of an atmospheric gas boiler is the characteristics of the chimney, which is responsible for the draft. If it is reduced, fuel consumption increases and the service life of the unit decreases.

At the same time, in capital construction, the task of installing a chimney requires related engineering solutions. In this regard, turbocharged boilers have an undeniable advantage, since the draft in them is artificial, and the air mass inlet-outlet pipe can be located both vertically and horizontally.

Compactness

Small size and weight (30-50 kg) wall-mounted gas boilers allow you to install them with the greatest convenience. Due to the fire safety of the isolated chamber, there are boiler models that can be built into furniture.

Flaws

In addition to the advantages, gas boilers with a closed combustion chamber also have disadvantages.

Noisiness

It is technically impossible to make the operation of a turbocharged boiler completely silent.

The highest quality boilers have noise-absorbing casings. To reduce the noise of any model, it is recommended to adjust the burner according to the device, this will correct its operation and help reduce the noise when the boiler is turned on.

High power consumption

Turbocharged boiler consumes more energy than atmospheric. Electricity is spent on electronic ignition, operation of automatics, circulation pump and fans. Connection of additional circuits, for example, DHW or condenser heat exchanger, further increases the energy consumption of the boiler.

Energy dependence

All turbocharged boilers without exception are energy dependent, since without electricity the boiler automation will not work. The problem of power outages is solved by connecting a gasoline or diesel generator, or by connecting an uninterruptible power supply (UPS), which leads to additional material investments.

Selecting a device

The choice of a specific model of gas boiler will affect the living conditions during minimum 5-7 years, so it needs to be taken seriously. Taken into account:

- power boiler - selected depending on the area of the heated room;

- Options for stabilizing electricity supply - generator or UPS;

- number of people, living in the premises - in case of need for hot water supply;

- DHW options - from the boiler circuit or by connecting an indirect heating boiler;

- water hardness in the region — determines the possibility of installing a model with a bithermal heat exchanger;

- housing layout: The distance between water intake points affects the efficiency of the DHW circuit.

Important! Before calculating the required capacity of a gas heating boiler, it is necessary to evaluate the heated premises for heat loss.

The rating of closed gas boilers by manufacturers is headed byt models from Germany. Models made from are of good quality. France and Italy. The quality of Russian boilers has improved recently, and their competitiveness is maintained due to their low cost.

Useful video

Watch the video, which talks about the features of chimneys for gas boilers with a closed combustion chamber.

Safe use of turbocharged boilers

Since the use of gas is a fire hazard, The automatic control of turbocharged boilers is activated in any potentially dangerous situations.

It is better to entrust the installation of heating equipment to specialists, since any violations may impair the operation of the unit and lead to the manufacturer's warranty being voided.

The regulatory documents for installation are the current ones SNiP, environmental safety requirements on harmful emissions and sanitary standards.