An unpretentious device that will heat any home! Pellet heating boiler

In private homes where there is no centralized gas supply, installing a pellet boiler will help solve the heating problem.

When heating with pellets Fuel costs are reduced and the combustion process is automated.

Pellet boilers are quite economical, which is why they are very popular.

Content

What is a pellet boiler for heating a private country house

A pellet boiler is a type of solid fuel boiler that operates using special combustible granules called pellets. Pellet fuel has a number of advantages:

- Low price.

- Convenient storage. Combustible pellets do not take up much space. Their length is 7 cm., and the diameter is 5-10 mm.

- Several bags of fuel enough for the whole winter.

Photo 1. Pellet boiler installed indoors. Nearby is a supply of pellets for burning in the device.

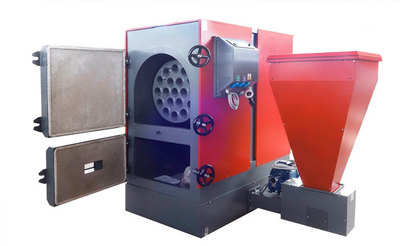

The device of the unit and the principle of operation

Pellet boiler consists of 3 elements:

- from a container equipped with a burner for burning fuel;

- from the convective system in which the heat exchanger is located;

- from a bunker containing a tank for combustion waste.

The device requires the following to operate: an attachment that ensures timely fuel supply. The pellet boiler is equipped with a control unit, which is used to set the operating parameters of the device.

Heat exchanger is being manufactured made of steel or cast iron. Foreign manufacturers prefer to use cast iron. It does not rust, but this material reacts poorly to temperature changes and weighs a lot. In Russia, models are equipped with steel heat exchangers. They quickly react to temperature changes, weigh little, but are prone to corrosion. Therefore, most manufacturers cover boilers with an anti-corrosion compound.

Pellets are fed into the boiler firebox, where they burn completely. Due to this, the coolant is heated., which distributes heat throughout the room.

The time of pellet feeding depends on the size of the bunker. Periodically It is necessary to clean the channels from accumulated emissions.

Advantages

- Operation of the device safe for the environment. Combustion materials do not contain any impurities.

- The unit is economical. Pellets in the boiler burn completely and are consumed in minimal quantities.

- Model range of solid fuel boilers diverse.

- The process of the device operation automated.

- When used correctly the boiler will serve for many years.

Flaws

- High price. Although the pricing policy of many manufacturers is democratic, not everyone can afford to buy a pellet boiler.

- Some pellet boiler models operate on electricity, so it is worth taking care of a power source or generator in advance.

Types of pellet heating boilers: fireplaces, devices with a water circuit

Boilers by type of fuel used there are:

- pellet;

- conditionally combined;

- combined.

Pellet boilers are used as fuel wood pellets. Continuous operation of the pellet device is achieved through stable and timely supply of pellets.

Conditionally combination instruments allow the use of briquettes, firewood and other raw materials. But burning alternative fuel is possible only in extreme cases. In this case, additional parts are attached to the boiler design. For example, a grate, which is installed in the firebox before loading firewood.

Combination boilers use several types of fuel. This is possible due to the presence of two or more fireboxes. Such devices are larger in size and more expensive.

By fuel supply type Pellet boilers are:

- automatic;

- semi-automatic;

- with mechanical fuel supply.

Automatic pellet products work without human intervention. It is enough to simply turn on the device.

Operation of the semi-automatic device is controlled by the processor, but the power is set manually by the owner. Periodically (no more than once a week) clean the ash pans. On average, this process takes 15 minutes.

Design mechanized pellet boilers the simplest, the devices are compact and cheaper than other models. The operation of the devices is completely dependent on the person.

Due to the small size of the bunker, the device will have to be loaded every 2-3 days.

By intended purpose Pellet boilers are divided into:

- for hot water heating models;

- for convection fireplace stoves;

- for hybrid installations.

Hot water heaters Heating boilers maintain a favorable temperature in the room and heat the water. Such equipment is suitable for small offices, private houses, cottages. But it is best to install the devices in the basement or in a specially designated place.

Convection fireplace stoves are used to heat small rooms. They are installed in the living room, are practically silent, have small dimensions and an attractive appearance.

Hybrid boilers are similar in appearance to stoves and fireplaces. The devices are equipped with a heating function using a water coolant. Some models have a hob and an oven.

Solid fuel boilers have the following types of burners:

- flare;

- volumetric combustion;

- fireplace.

Torch burners are unpretentious. They are suitable for cottages where uninterrupted operation of the device is not required. The disadvantage is the unidirectionality of the torch fire, which locally heats the walls of the boiler.

Volumetric combustion burners are installed in high-power industrial boilers. Such devices are undemanding to the quality of pellets.

Fireplace burners are best suited for small boilers. They are not very efficient, but reliable.

Factors influencing choice

When choosing a high-quality, reliable unit, pay attention to the following characteristics:

- For power. Household appliances have relatively low power. To provide heat to a living space it is enough 15 kW. For 10 sq. m. have to 1 kW. A boiler with this power can heat a house the size of 150 sq. m.

- On the efficiency factor. Pellet boilers have varying efficiency from 80 to 95%. The high performance is achieved due to the quality of the granules and the design features of the device.

- By burner type. There are retort and stoker burners. The former have smoke directed upwards. They are undemanding to the quality of fuel and function for a long time without cleaning. The efficient operation of a stoker burner is achieved due to the high quality of the loaded granules. The main disadvantage of such a device is that it often gets clogged.

- To the level of process automation. Some pellet boilers can operate without human intervention. Such devices are controlled remotely using a mobile phone. A special program allows you to turn the device on and off remotely, adjust the temperature. In case of a malfunction, information about the failures is sent instantly to the mobile device.

- On the design of the heat exchanger. They can be horizontal and vertical, flat and tubular. Experts recommend choosing vertical heat exchangers with turbulators, which spend most of the energy on heating the coolant and do not allow ash to settle in large quantities.

Binding schemes

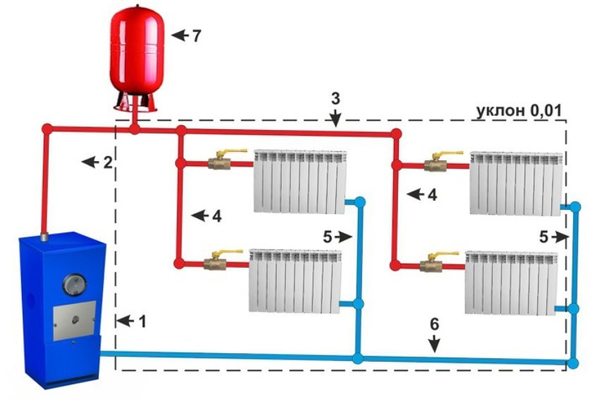

Binding diagram depends on the principle of movement of the coolant through the pipes. The systems use natural or forced circulation.

Features of natural circulation

The coolant moves naturally through the pipes. There is no pump in such a heating system. Here circulation occurs exclusively according to the laws of physics: the colder environment displaces the hotter and less dense one.

Photo 2. The piping diagram of a pellet boiler with natural circulation. For its correct operation, a certain slope of the system is required.

Advantages of the system heating with natural circulation:

- low cost of the boiler and ease of installation;

- cheap maintenance;

- quick restoration of work in case of breakdown or failure.

Flaws:

- This piping scheme is used only in a single-circuit system.

- The harness is suitable for small-sized rooms.

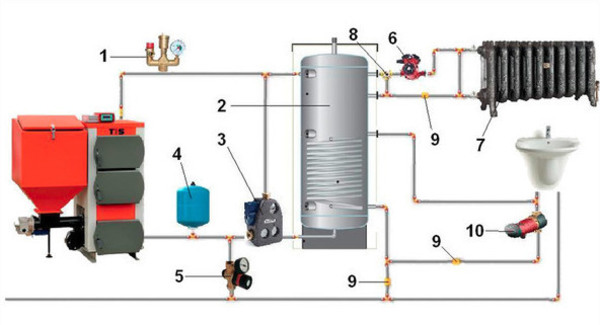

With forced circulation

The circulation pump in the heating system makes it possible heat houses and production premises of any size. Such a heating system has its disadvantages:

- Expensive installation.

- Complex scheme. It consists of a large number of elements, so an ignorant person will not be able to understand all the details.

- The elements of the home heating system must be aligned with each other.

- Dependence on the availability of electricity. The circulation pump will only operate when power is supplied to it.

Photo 3. The piping diagram of a pellet boiler with forced circulation. A special pump is installed in the system.

Purpose of the UPS

Models of solid fuel boilers whose operation depends on the power grid, react to voltage surges and power outages. Such failures lead to serious breakdowns.

In winter, you can't let the entire heating system fail. Avoiding such situations will help installation of uninterruptible power supplyIt will ensure stable voltage in the network and continuous operation of the boiler.

Making an economical device with your own hands

The pellet boiler has a fairly simple design, so it is easy to assemble with your own hands. For this, you will need steel pipes or sheets 3-5 mm thick, grinder and welding machine. If you have not previously had to deal with welding work, contact a professional.

The main element of the boiler is heat exchanger. It is better to make it rectangular in shape. from square section pipes. To do this:

- Pipes of the same size are taken.

- A round window is made in the vertical post.

- Holes are cut in the front pipes for drainage (one for cold water, the other for hot water).

- The structural parts are connected using a welding machine.

To ensure that the seams are even, it is best to position the posts on a flat surface.

Before carrying out installation work, the device is tested for strength:

- the device is positioned vertically;

- close the bottom hole;

- pour water into the container.

Attention! The structure should not allow liquid to pass through, even in small quantities. Otherwise, welding work needs to be done again.

After the boiler has been assembled and tested, its installation begins. There are simple rules for installing this device:

- The boiler should be installed in a non-residential area, for example, in a basement.

- It is worth taking care of the floor covering in advance. It is important that the floor is concrete or made of ceramic tiles.

- The room must be well ventilated. The air humidity and temperature in the room with the boiler are monitored.

- The boiler room should not be small in size, as it will be inconvenient to carry out maintenance work in it.

Useful video

Watch a video that talks about choosing the right pellet boiler.

Practical advice

Pellet boiler - practical and productive system. The device is easy to use: just pour fuel pellets into the hopper and light the firebox.

- Chimney for boiler equipped with a stainless steel elbow. The higher the tap, the better.

- Pellets are stored in a dry place.

- It is recommended to supply the pellet boiler with additional storage tank, which will allow you to save up to 30% of fuel.

Many models start automatically. Compared to gas heating, savings when using a pellet boiler are 40%, and in comparison with electric heating - 60%.

Comments