Which brick is suitable for barbecue and which one should not be used?

Owners of country houses often think about building a barbecue on the site. The main problem that can be encountered in this case is selection of base material.

Buying unsuitable or low-quality bricks from construction sites will make all further work pointless, since a barbecue made from them will not last long.

There are several optimal types of bricks suitable for laying out the firebox and several types for facing.

Among them there are beautiful and affordable ones that can withstand the temperature of the external and internal environment, do not dry out, do not crack in the heat, and do not soften in the rain.

Content

- Barbecue bricks - which ones to use when building ovens

- The process of building and finishing a brick barbecue

- What kind of brick is needed for barbecue ovens?

- How to use old brick

- Additional attributes of a brick barbecue oven

- How to check the quality of bricks?

- Prices and brands

- Calculating the number of bricks needed to build a typical barbecue oven

- Useful video

- Conclusion

- Comments (2 opinions)

Barbecue bricks - which ones to use when building ovens

To create barbecue ovens, ordinary, facing and fireproof bricks are used.

The need to purchase facing material arises if no materials are used in construction special stove bricks or to maintain an attractive appearance while saving money by using old bricks.

Marking of optimal solid firebricks — M-250, M-200 or, as a last resort, M-150.

Main types of bricks - deciding on the choice

To understand what materials to use for a brick barbecue oven, you must first understand the characteristics and basic parameters by which they are distinguished.

By application:

- ordinary construction;

- refractory;

- clinker - facing.

By composition:

- sand-lime brick;

- fireclay;

- ceramic;

- hyperpressed.

By internal structure:

- hollow;

- full-bodied.

It can be difficult to differentiate between brick barbecue materials by appearance, so you need to pay attention to the markingsIt contains encrypted information:

- Strength grade — the higher the indicator, the stronger the brick, the better it can withstand loads without mechanical damage. It ranges from M-25 to M-500;

- Internal construction - no designation for solid ones, "P" for hollow, "U" for thickened;

- Weight, size — to calculate the future load on the foundation;

- Manufacturer's abbreviation or title;

- Frost resistance — from F-15 to F-75, indicates the ability to withstand a certain number of freezing and thawing cycles without losing strength;

- Water absorption (%) - a minimum indicator is required for the construction of the foundation, not particularly important for the rest of the barbecue oven structure;

- Material of manufacture.

The process of building and finishing a brick barbecue

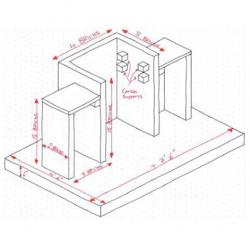

If you have decided which brick to choose for building a barbecue oven, you can proceed directly to its construction (using the example of a 70 cm high barbecue oven with a woodpile).

Foundation

Photo 1. Two people lay out bricks on the prepared foundation to calculate the dimensions of the future stove.

- In the construction of barbecue ovens it is mainly used strip foundation — gravel and sand are poured into a 30 cm deep trench and compacted. It is not as expensive as tile, but it is not as durable. Therefore, it is advisable to strengthen it with a thin layer of concrete on top.

- Formwork is installed from boards, and a structure is formed inside metal frame.

- The structure is being poured concrete; the mortar for laying barbecue outside sits for several weeks.

Base

Bricks: regular full-bodied, since this part of the structure is not exposed to high temperatures.

Bonding mortar for laying barbecue mixed with clay and sand. Bricks are laid around the perimeter of the foundation at a distance of 0.5 cm from each other.

Fuel tank

Bricks: only fireclay refractories, since the firebox must withstand high temperatures during use.

Standard size of firebox: 3 bricks deep, 5-7 rows wide.

At the level of the supposed bottom of the firebox, a ledge is made to arrange the location of the coals - a box or a metal sheet. The next ledge will be after 2-3 rows - for the grate where the food will be cooked.

Attention! An angle grinder can be used to create half bricks.

The construction of the firebox ends with a rectangle, on the top row of which a hood made of sheet metal will be placed.

Chimney

Bricks: only fireproof, for the last 2 rows you can use regular bricks. The chimney gets very hot because of the hot air coming out of it, but regular bricks can withstand the temperature of the last 2 rows.

The chimney should be lined with fireproof material., as it must withstand high temperatures. The furnace damper is also located here.

If a metal or asbestos-cement pipe is placed in the chimney, the space between it and the walls is filled with concrete.

What kind of brick is needed for barbecue ovens?

Sizes may vary, but they are mainly produced according to the German standard with dimensions 250*120*65 mm, weighing 4.3 kg, thickened ones make - 250*120*80 mmThere are also modular ones, they have dimensions 288*138*138 mm.

The grade and type are selected depending on the part of the stove that is being laid out.

Please note that It is prohibited to build barbecues from sand-lime bricks due to the properties of the material it is made of. It is also not recommended to use bricks with holes or hollow ones.

- Regular red 1st grade (from M-100 to M-150) — uniform color inside and out; few or no hairline cracks on the surface; breaks into large pieces when hit hard on the ground, but does not crumble; used for laying foundations, external walls, and chimneys (if the barbecue oven with a small firebox is not planned to be used continuously).

- Regular 2nd grade — pale pink; has low frost resistance, high percentage of water absorption; is used when laying non-critical sections of the structure — horizontal and vertical sections, if the barbecue oven is built indoors.

- Regular 3 grades - brown in colour; not suitable as a material for brick barbecues, only suitable for foundations, together with gravel.

- Refractory fireclay (250*125*65, 230*113*65 mm) - of different but uniform colors; it is used in the construction or lining of the firebox, the lower part of the chimney.

Attention! In Russia, you can see bricks with protrusions on a larger surface, which were intended by manufacturers to provide better adhesion. Unfortunately, in practice, they did not justify themselves - barbecue ovens, on the contrary, became less durable and long-lasting.

How to use old brick

Photo 2. A pile of old bricks - from such stocks it is quite possible to choose a brick suitable for building a barbecue.

If you have old bricks, while they have not lost their strength and shape, they can be used in the process of creating a barbecue oven. Before re-laying, they must be cleaned of old mortar. They are suitable for the construction of a foundation, a chimney, but not for a firebox.

Attention! If lime mortar was used during the first laying, such bricks are only suitable for laying the upper part of the chimney when pouring the foundation.

Additional attributes of a brick barbecue oven

The finishing can be done with facing material or heat-resistant tiles. Don't forget to create a protective platform from such tiles in front of the front part of the barbecue oven!

It is convenient to place a work table nearby, a wall with a canopy for kitchen utensils. Ordinary or old bricks are suitable for construction. The tabletop is filled with liquid stone, thick plywood with tiles is attached or ready-made is bought.

A profitable solution is to supply electricity to create lighting and install sockets.

How to check the quality of bricks?

Photo 3. Row by row, the master lays out the walls of the barbecue oven. Light taps with the handle of the trowel on the surface of the brick help to lay it more tightly.

The following methods can be used to selection of quality materials:

- By chips - one unit of the product is purchased, split in two and examined. The mass inside should be homogeneous, without pieces of clay or other inclusions. Such phenomena indicate a violation of the production technology;

- By appearance — with smooth edges and dimensions not exceeding the standard by 2 mm;

Attention! A mica-like film on the surface indicates an inability to withstand sudden temperature changes.

- By ear - a clear metallic sound after hitting with a hammer indicates a quality product, a dull sound indicates cheap raw materials, poor drying and hardening. After checking by ear, there should be no dents or chips left on the surface.

All these methods will help you choose which barbecue brick to use from the stock you already have.

Prices and brands

The cost of materials for a brick barbecue depends on the manufacturer, the quality of the product and its variety.

- Red solid brick M-200 (Vitebsk workshop) - 25 rubles/piece.

- Fireclay firebrick SHA-5 (TD Rosogneupor) - 50 rubles/piece.

- Facing brick MATTONE LATERA — 20-27 rubles/piece depending on color and texture.

- Used bricks - 6-11 rubles/piece.

The most popular brands are:

- Victory And Legend (Russia, St. Petersburg);

- Grater (Estonia - Russia - Germany - Belgium);

- Vitebsk workshop (Belarus, Vitebsk).

- Lode (Latvia);

- Borovichi (Russia, Nizhny Novgorod);

These are the brands that experts most often choose when purchasing barbecue brick and choose which material to use.

Attention! When purchasing fireproof materials from unknown manufacturers, marking is required.

Calculating the number of bricks needed to build a typical barbecue oven

To calculate the required amount of material, it is enough to count number of bricks on the drawn drawing. For this project you will need (in rows): 49+49+32.5+34+33.5+34.5+30+29.5+42+37+41+27+27+27+27+27+36+27+36.5+27+27+23+26+37.5+37.5+31+30.5=886 pieces.

Attention! Don't forget to buy an extra 10% of materials in case something goes wrong.

Useful video

The short video below will tell you more about the different types of bricks and what each brand is intended for.

Conclusion

With little material and labor costs, it is easy to build a barbecue oven for a pleasant and tasty rest in company. Now you knowwhat kind of brick to make a barbecue fromstove on your summer cottage. After reading the article, you can immediately start purchasing the necessary material and immediately begin construction.

Comments

It is best to use thick-walled steel pipes when necessary.