Heating for pennies! Features of a waste oil heating boiler

Waste oil is a petroleum product that is formed as a result of the car engine. It is also the most profitable type of fuel for the heating system of a private house.

The structure is being redesigned to save on gas, electricity, etc.

Content

Heating with waste oil for a private house

Used oil for heating was initially used together with diesel fuel. This method proved its effectiveness and economy. Then they decided to make the product even cheaper and removed diesel fuel from the composition. Used oil by its characteristics It resembles diesel fuel, but is much cheaper.

Photo 1. This is what waste oil used for heating looks like. The liquid is dark brown.

Features of use

The waste is used as fuel in a special boiler or furnace. Only this guarantees complete combustion of the product without the formation of smoky smoke. Heating system refurbishment or installation of a new circuit pays for itself in the first year use of the product.

Types of fuel. How much heat is obtained when burning one liter?

Burning one liter of such fuel gives 10-11 kW heat in 60 minutes. The pre-treated product has more power. Its combustion gives 25% more heat.

Varieties waste oils:

- motor oils and lubricants used in various types of transport;

- industrial products.

Pros and cons

Advantages of fuel:

- Economic benefit. Consumers save money on fuel, but the biggest benefit goes to businesses. Selling waste eliminates the costs of storing, transporting and disposing of the product.

- Conservation of energy resources. Refusal to use gas and electricity for heating prevents the depletion of sources.

- Environmental protection. Due to the high cost of disposal, owners of enterprises and vehicles got rid of oil by pouring it into water bodies or into the ground. This had a negative impact on the environment. With the beginning of the use of waste as fuel, such manipulations ceased.

Disadvantages of fuel:

- poses a health hazard if the product does not burn completely;

- large dimensions of the chimney - 5 m in length;

- difficulty of ignition;

- the plasma bowl and chimney quickly become clogged;

- The operation of the boiler results in the combustion of oxygen and the evaporation of moisture from the air.

How is oil processed?

Waste oil is obtained by burning any type of oil, but it is usually used for heating a room. petroleum refining products from internal combustion engines.

Also from industrial machinery, compressors and power equipment.

What does not apply to such fuel?

List of products not related to waste:

- processed oils of vegetable and animal origin, which are used for household needs;

- solid waste with processing;

- solvents;

- products that cannot be processed in the same way as waste;

- natural petroleum fuel from spill;

- other unused petroleum products.

How to choose a heating device?

Selecting a device for a heating system depends on the area and shape of the room.

Fireproof furnaces on waste oil, device with water circuit

It is recommended to install such a stove in a one-story building without walls or other partitionsThe unit guarantees fast and economical heating of the building.

The device is functioning based on the principle of feeding the product in drops onto a hot bowl or a combustion chamber plate. This is how the product ignites and heat is transferred to the walls of the firebox, and from there the air is heated.

Waste oil furnace rarely fails. The device is easy to make with your own hands. The unit is small in size, so it does not take up much space in the room and is easy to transport. The oven is suitable for heating food on top of the device.

It is allowed to combine the furnace on the return line with water heating. For such a circuit A metal tank is placed on the source. The return flow is diverted from the bottom of the tank, and the feed from the structure is connected at the top.

Instead of working off, It is prohibited to use any kind of flammable substances. Such elements should also not be kept near a heat source during operation.

Attention! Oil must not come into contact with water, otherwise it will flare up. If a fire occurs, do not use water to extinguish it. The flames are knocked down only with a fire extinguisher, which is installed near the stove.

During operation of the source The ventilation system must not be closed. This will cause carbon monoxide poisoning.

Waste oil boilers

Waste oil boilers are recommended for use for heating large areas.

Photo 2. A type of boiler operating on waste oil. The device is presented in yellow and red, manufacturer Thermobile.

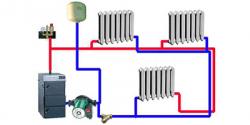

The pump transmits fuel supply to the injector. At the same time, this happens oxygen injection. This allows ignition and heat distribution from the source to the radiators.

For optimal ignition, it is essential to preheat the fuel to a temperature 71 °C. A burner is used for this. Instead, they also use two- or three-way heat exchanger with large-sized pipes. Any of these devices optimizes the operation of the equipment.

Diesel heating

This heating method is used to heat suburban properties and garages.

What does it represent?

This type of heating has a similar operating principle to a water circuit, but there are some nuances. The boiler that heats the coolant runs on diesel fuel.

The liquid is distributed throughout the system and returned back using a circulation pumpAfter the coolant is heated, the source stops working and resumes working after cooling.

Advantages and disadvantages

Advantages of diesel heating:

- automated boiler operation;

- independence from central heating, thanks to which the user turns the heating on and off at his own discretion, based on the outside temperature;

- the prevalence of fuel that can be purchased at any gas station.

Flaws:

- high cost of diesel fuel;

- high price of equipment and components.

How to make a waste oil boiler with your own hands?

To make the unit you will need:

- sheet steel, thickness 4 mm;

- metal pipe for air exhaust;

- section of reinforcement 8 or 10 mm in quantity of four pieces;

- welding machine;

- pump;

- compressor;

- asbestos;

- expansion tank;

- Bulgarian;

- heat-resistant sealant;

- burner tees, elbows and corners;

- steel adapters.

Assembling the case

Operating algorithm:

- Use a grinder to cut the pipe up to the level of the meter cylinder;

- shorten another smaller pipe with a grinder to the same level 20 cm cylinder;

- in two plates make two holes that correspond to the diameters of the pipes;

- meter cylinder cover with plates and weld them in a circle, the plate with a large hole is fixed from below;

- weld a small cylinder to the edges of the hole and cover it with another plate;

- make holes in the pipe for ventilation;

- attach legs to the bottom.

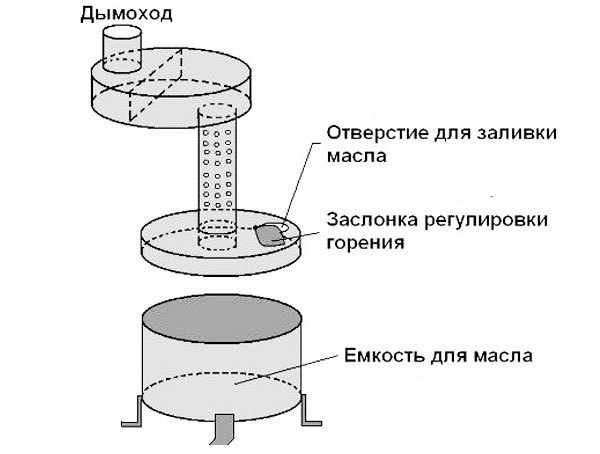

Photo 3. Scheme of a boiler operating on waste oil. Such a device is easy to make with your own hands.

Mounting the burner

Made of sheet steel, 3mm thick, make a burner cover so that its size corresponds to the dimensions of the nest in the boiler. Using couplings and tees from the corners, make a burner body using a welding machine. This design will require adapters for half a two-inch nipple to connect the waste feed to them. Before screwing the threads, treat it with a sealant.

Take it 2 steel plates - one large, one small, bolts, nuts and asbestos. Cover the tubes and the inner surface of the adapter with asbestos. Fix the material on the adapter in two layers using a sealant, and on the tubes - with wire. Fix the torch in the socket.

Insert a small steel plate into the housing socket and place a rolled-up asbestos sheet in 5 layers. Drill holes for fasteners in the other plate. Place it on the canvas and attach both plates to each other using bolts.

Installation of the body and chimney

It is recommended to place the boiler in a corner, after removing the covering from the floor and walls.

The device is installed on concrete or fireproof tiles.

All furniture items are moved away from the unit.

After installing the boiler, secure a vertical chimney of the following dimensions in it: 4 mInstall a damper on the pipe to control the draft.

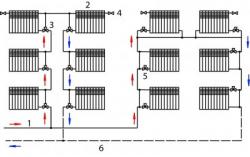

Connection

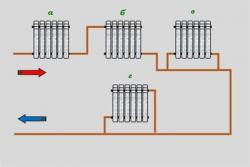

Install radiators and pipes for the heating system. Weld a large round metal container to the boiler lid or secure it with bolts. Make a hole at the top and run pipe for supplying coolant to the circuitMake a hole at the bottom and connect the return line.

Features of heating in the garage

It is recommended to use a waste oil stove to heat the garage. Gasoline, kerosene and other similar substances must not be stored near the device. Used engine oil from the car is used as fuel. Consumption — 1 liter per hour.

The boiler lid is used as a hob for heating food or water.

Useful video

Watch the video, which demonstrates the operation of a homemade waste oil boiler.

Safety rules

When using waste oil for heating It is recommended to follow safety rules:

- the source must not be located near walls finished with flammable materials;

- It is prohibited to use flammable substances to light the oil, as this will lead to ignition and, as a consequence, a fire will occur;

- the unit is not placed on a floor covered with linoleum, carpet or other covering;

- the stove cannot be extinguished, therefore, before using it, the operating time and amount of fuel are precisely calculated;

- The oil must not contain water, antifreeze or any other liquid.

Waste oil - the cheapest type of fuel. This explains the increased demand for this product.

Comments