Its advantages are hard to dispute! Closed heating system: what is it

When heating private houses, a closed heating circuit with forced circulation is mainly used.

The coolant in such a scheme does not evaporate. due to the lack of contact with the environment. This makes it possible use special compounds in addition to water, increasing heating efficiency.

Content

Closed heating system: what is it, operating principle, pros and cons

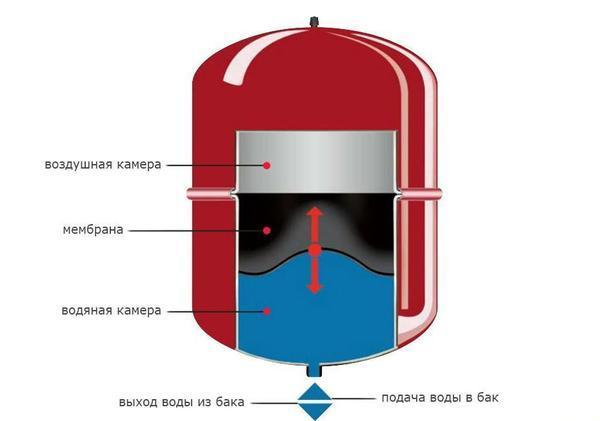

Expansion capacitors are used in such circuits. membrane tanks. Sealed container is divided into two parts by an elastic membrane.

As the temperature increases, the valve opens and excess liquid moves into the tank.

When the temperature drops, the coolant flows back into the system, which maintains a stable pressure in the latter.

Non-pressurized tank can be completely filled with liquid, so the pressure maintenance unit must be more compact than a conventional tank. It allows you to adjust the specified parameters in the circuit and automatically feed the structure.

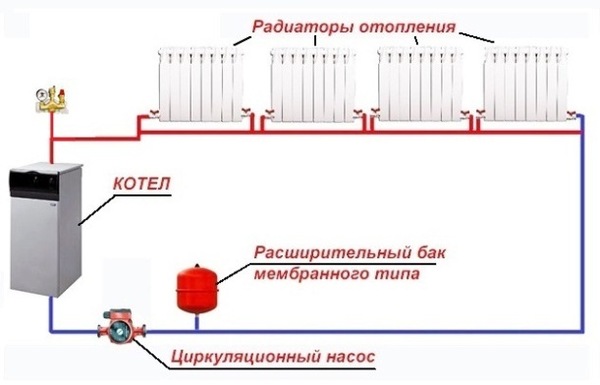

Closed loop consists of the following elements:

- from a sealed membrane tank;

- from batteries (radiators);

- from the heating boiler;

- from the circulation pump;

- from pipes;

- from connecting elements (valves, taps, filters).

Closed heating system has a number of advantages:

- the possibility of using any coolant;

- durability of the structure due to complete tightness;

- absence of unnecessary noise;

- the ability to install the system yourself;

- high speed of liquid movement, ensuring maximum heat transfer;

- no need for thermal insulation for the main line;

- reducing financial costs for heating the house.

The disadvantages include: dependence on electrical energy and the need to purchase a large membrane tank, the price of which is quite high. The problem of energy dependence is solved by installing uninterruptible power supplies or small generators that provide emergency power supply.

Construction schemes, use in apartment buildings

It is used in private houses one-pipe or two-pipe heating circuit.

One-pipe scheme It is used in small areas where heating is required. no more than five radiators.

Photo 1. Scheme of a closed heating system with a single-pipe circuit. Each of the radiators is connected in series.

All batteries are connected in series in the circuit, so the last heating device will always be colder than the first ones. The obvious advantage of such a circuit is lower pipe consumption.

If one battery fails, the others will continue to operate normally. when using bypass. One-pipe system can be horizontal and vertical. The horizontal one does not allow to regulate the amount of the coolant, therefore bypasses are installed when laying it. The vertical single-pipe circuit is used in most cases in multi-storey buildings.

Two-pipe (two-circuit) scheme heats the rooms more evenly. The liquid from the heat generator to the batteries circulates along two circuits. In this case, the radiators are connected in parallel. The coolant has the same temperature in all batteries. This method requires much greater costs, but it makes it possible to regulate the temperature in each room.

Calculation

In order to correctly select the circulation pump and pipe diameters, hydraulic calculation of heating systemIt allows you to identify hydraulic pressure losses in specific areas and minimize operating costs.

Attention! It is advisable to install a circulation pump in the return line. In this case, the service life of the device will increase, since the cooled coolant will already pass through it.

Calculations are carried out by a specialist using heat engineering calculations and after selecting batteries. As a result of the calculations, the pressure value required for running water through the circulation pump will be obtained. After this stage, the value for determining the volume and selecting the membrane tank is calculated.

How to start the coolant in the system?

When filling a closed contour there should be no air pockets left.

If the heating circuit is connected to the water supply using a tap, then in order to fill it you need to periodically open the valve and release the displaced air from radiators.

This process continues until all excess air is released and the pressure reaches the required calculated value.

To fill a circuit not connected to a water supply a pump and container are required, from which the coolant will be pumped. Before supplying it, all the taps on the radiators must be opened. The drain nipple is connected to the pipe, and the structure is filled with the help of a circulation pump.

Important! When filling the heating circuit with coolant it is necessary to close the taps in timeto prevent leaks.

Setup and launch

After the coolant has been launched into the structure check all circuit connections. Before this, the air must be pumped out of the pump, otherwise the operation of the device may be disrupted. Next, you need to go around all the batteries and do the same procedure, slightly opening Mayevsky cranes.

The air is released until water starts to flow from the radiators. After this, the pressure value is checked using the measuring device. If it below 1.5 atmospheres, then liquid is added again, and the process of de-airing the equipment is resumed.

Then The system is being pressure tested. The pump pumps the coolant into the pipes until the pressure increases to 1.5-2 times.

The heating structure is left in this state. for 15 minutes, after which the pressure is measured again. If the readings on the measuring device have changed, then there is a leak somewhere.

Otherwise, the system returns to operating pressure by draining excess coolant.

The final step is - starting the heat generator, which is already prepared for use and connected to the network. The equipment thermostat is set to a low temperature (40—50 °C), time is given for the entire volume of the coolant to warm up. After this, all radiators are checked. If the upper parts of the batteries are colder, the air is bled again.

After that increase the temperature of the liquid (up to 70-80 °C) and leave the heating circuit for some time. If in this mode the heating devices continue to operate normally, and the temperature of the liquid in the return pipe by 20 °C colder than heated, then the system functions properly and does not require additional settings.

Features of a heating circuit with a membrane expansion tank

A closed-loop circulation pump allows you to organize the design according to any scheme, regardless of the hydraulic resistance indicator. Forced circulation gives the ability to use different options for organizing heating:

- sequential arrangement of radiators;

- collector circuit;

- warm floor.

Membrane expansion tank and circulation pump can be located together with the heat generator in the same room. This reduces the overall length of the pipelines, so when organizing the heating circuit, there is no need to install large-diameter pipes and pay attention to the angles of inclination.

Photo 2. Diagram of the structure of a membrane tank for a closed heating system. The arrows indicate the parts of the structure.

Why does the pressure drop?

The reasons for the drop in pressure may be:

- malfunctions of the heat generator (heating boiler);

- coolant leaks;

- excess air;

- aluminum radiators.

The leak may not be visible. To detect it, use special devices: thermal imagers or ultrasonic devices. It is necessary to carefully check the sectional connections of the radiators, because their surface may be covered with corrosion. Rusty streaks indicate damage to the batteries.

In order to detect a leak you need to press on the nipple, which is located on top of the expansion tank. If water and air are released when pressed, then you can safely conclude that there is a leak.

Closed-type heating with safety group

Safety block in the heating circuit — is a set of devices that prevent emergency situations. Any heating structure operates at certain pressure values. Depending on the heating or cooling of the coolant, this value varies. The safety group monitors it and, if the maximum permissible value is exceeded, discharges a certain amount of liquid from the circuit.

The system includes the following devices:

- A pressure gauge that measures the pressure in the installation.

- A valve that prevents pressure from increasing.

- An air vent that removes excess air.

Photo 3. Safety group for the heating system, including a pressure gauge, air vent and check valve.

All these devices have their place and are placed on a separate collector, which is connected to a closed heating circuit with a threaded coupling.

Important! Safety devices are always installed only vertically and above the heat generator.

Some boilers are for sale together with the safety group installed by the manufacturer. The remaining devices require separate installation, which is carried out in the same room as the boiler.

The closed design of the heating system is very popular and has many advantages. With proper adjustment, start-up and installation, it becomes autonomous and does not require any outside intervention. The system is easy to maintain, and if problems occur, you can restore it yourself.

Useful video

Watch the video, which explains how to properly fill a closed heating system with coolant.

Conclusion

If the design, calculation and installation of the heating system structure are done correctly, then it will work smoothly for a long time.

Comments