Step-by-step instructions on how to make a warm floor in a house from central heating. Advice from experts

Underfloor heating can be the main heating of a house or a comfortable heating of the floor covering.

You can make it yourself: run from the central heating pipes.

Content

How to make a warm floor in a private house from a heating system with your own hands

To make warm floors from a heating system with your own hands, you will need remove floor covering, place the pipes on the slab and make a concrete screed, then make a new flooring.

Removing floor coverings

The dismantling technology depends on the material:

- The tiles are removed using a tool with a thin edge.: spatula, screwdriver, chisel and hammer. The spatula or chisel is inserted with a shovel between the tiles and the floor, tapping them with a hammer. This method allows you to remove the tile entirely. You can remove the old coating with a drill, drilling holes between the tiles and the floor, or with a hammer drill in the "chasing" mode. However, with such dismantling methods, the tiles often break into pieces.

Photo 1. Removing tiles with a drill is quick, but tiles can break.

- The boards or parquet are lifted using a chisel, hammer, crowbar, or nail puller.

- Laminate can be dismantled without tools. Its panels are attached to the grooves-protrusions without gluing to the floor or to each other. They are slightly moved away from each other, and the outer panel is lifted up. After which it "snaps out" of the groove of the adjacent panel.

Installing a damper tape

The damper tape is made of soft heat-insulating material – foamed polyethylene 15 cm wide and 0.5 to 1 cm thick. It is laid along the perimeter of the floor along the wall. After pouring the screed, the tape will be a damper barrier between the screed and the wall of the room. to compensate for possible expansion of concrete when the temperature changes. In addition, it will limit heat loss.

Width The tapes are selected according to the height of the future screed. It should rise 2–3 cm above the finished floor levelAfter all work is completed and the decorative flooring is laid, the edge of the tape is cut flush with the floor.

Thermal insulation

Underfloor heating pipes insulate from below, to prevent heat leakage. In ground floor apartments above cold basements or arches, insulation is reinforced.

Foam plastic (polystyrene foam) is used for thermal insulation of underfloor heating. thickness from 3 to 10 cm. Density of insulating boards determined by temperature rooms under the floor. If there is a street below (apartment above the arch) - you will need polystyrene foam with a thickness of 8–10 cm. If it's a basement, that's enough 5-6 cm foam plastic. If there is a residential apartment under the floor, they put 2-3 cm insulator.

Photo 2. Laying foam plastic is necessary for thermal insulation to prevent heat leakage in the room.

In rooms with low ceilings, foamed polyethylene is laid on the floor, The thickness is 1-2 cm.

Important! Are being released special foam insulation for floors with protrusions-bosses, between which it is convenient to lay and fix pipes.

Laying reinforcement

To prevent the pipes from cracking under the weight of concrete and furniture, the floor screed is reinforced metal mesh. Use a mesh made of a rod with a diameter 3-4 mm with cell dimensions 100x100 mm. The mesh for concrete reinforcement is placed on top of the metal-plastic pipes. A plastic mesh is placed underneath the pipes to fix the pipes during the process of laying them out on the floor.

Laying polystyrene

This material is created under the influence of a blowing agent, by means of thermal swelling of polystyrene granules.

Each such granule contains many small cells that are filled with air, which is why the polystyrene foam boards are soft.

For the production of floors under the screed, it is recommended to use extruded expanded polystyrene grade 35 (C35). Standard sizes of polystyrene foam sheets are – 1250x600x20, their thickness is 30, 40, 50, 60, 80, 100 mm.

Before starting work, you should calculate the amount of material required.

Types of installation and cutting of pipes

Metal-plastic pipes are used for floor heating. They can be bent, laid in a spiral, which makes their installation easier into the warm floor.

Metal-plastic pipes are used for installing heated floors. with a diameter equal to the cross-section of the pipes central heating, or with a slightly smaller cross-section.

To fix them, use metal reinforcing mesh. The pipe is fastened to it with a plastic clamp or wire, electrical tape, or scotch tape. This fixation is temporary, until the concrete is poured.

Before cutting the pipes into the surface of the insulation, the lines of their future location are marked. Heating circuit diagram may have the form of a spiral or a serpentine.

With spiral When laid, the entire surface of the room is heated equally. In the case of "snake" - one side of the floor will heat up more. Pipe laying pitch (distance between adjacent turns) varies between 15 and 30 cm.

Attention! The length of the pipe in one circuit should not exceed 50 m for a two-pipe system and 30 m for a single-pipe. Otherwise, in a large room it is necessary to arrange two or three floor circuits.

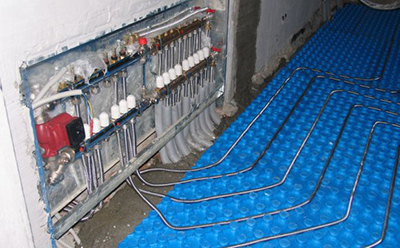

Pipe outlet to the distribution point

The pipes are connected to the central heating system through the distribution manifold. For this purpose, their edges are brought out to the distributor on the wall of the room. At the junction of the floor and the wall, the pipes are fixed to the mesh with clamps.

Important! When connecting pipes of adjacent circuits to the manifold should not intersect with each otherThis is important for the floor of a large room, which may have two or three heating loops.

When laying, it is necessary to take into account that the pipe must be continuous along its entire length inside the screed. Joints inside the concrete are not allowed. Pipe connections are made using metal press fittings or steel ball valves.

Correct connection to central heating

To connect the heated floor to the central heating system in the apartment, a number of additional devices and equipment are installed. Without them water will not flow into the circuit on the floor.

At the entrance to the apartment heating system, the following is built in:

- pressure equalization device (to prevent hydraulic shocks);

- air exhaust system;

- filter for cleaning the coolant.

The temperature of the water in the central heating often reaches 80 °C, while its temperature in the screed should not exceed 40 °C. Therefore, at the entrance to each circuit, a unit for mixing incoming and return water is built in. In it, hot water is mixed with cooled water.

Each circuit is built in circulation pump. Ball valves are installed after the mixing unit. They regulate the floor heating temperature: when fully open, more water enters the pipes and the floor heats up more. To reduce the temperature, the valves are partially screwed down.

Pouring the screed

It is necessary to add to the concrete solution for pouring the screed plasticizer. This substance makes the mixture more fluid by compacting it, which also affects thermal conductivity. After the concrete with the plasticizer has hardened, The screed conducts heat better.

The thickness of the underfloor heating screed above the pipes should be at least 30–40 mm. This will ensure uniform heat distribution over the surface. The maximum thickness of the screed over the pipes is limited 60 mm. The floor height is higher 60 cm complicates heat transfer and heating of the screed.

Photo 3. Floor screed with concrete mortar with the addition of a plasticizer, the thickness should not exceed 60 mm.

The hardening time of concrete is 28 days. The concrete will gain its initial strength much earlier. But you can turn on the heated floors and check their operation only in a month after pouring.

Floor covering arrangement

The covering is being arranged a month after pouring the floorDuring this time, moisture evaporates from the concrete, so it cannot be covered with decorative flooring.

The best option for finishing coating for underfloor heating is ceramic tiles. It transmits heat from the heated concrete screed into the room better than other cladding. For flooring in residential premises, they lay linoleum or laminate.

Reference! The most economical option for underfloor heating is thin linoleum without backing.

Testing

Warm floors are connected to the heating system, after which they are filled with water and checked:

- operation of ball valves;

- operation of the bleed valve;

- pressure gauge readings of the leveling device;

- possibility of adjustment.

The purpose of testing is safety check of work heating systems.

Useful video

The video clearly demonstrates the initial stages of laying a heated floor and connecting it to the heating system.

Can everyone install heated floors?

How to properly install warm floors from central heating in an apartment or private house not so easy, as it seems at first glance, but some of the work can be done independently: remove the old covering, lay thermal insulation and pour concrete screed.

As for laying pipes, this work must be done according to a finished project and a properly drawn up diagram.

Consultations and advice required help from professionals connection to the central heating system and testing the operation of the heated floor.

When connecting to central heating, it is necessary to take into account that an additional increase in the length of the heating circuit in a separate apartment may affect the quality of heating of neighbors' homes.

Installation of additional heating requires coordination with the housing officeIt is necessary to issue a number of documents and permits that will confirm the quality of the installation and the safety of the heated floors.

Comments