Forget about batteries and heaters! Heating with water floor is the best solution for a house or apartment

A water heated floor is a system for heating an apartment, where the heating element is flooring connected to pipes or electrical wiring.

Connects to both local and central heating.

Water heating

The thermal circuit is located in the concrete screed between the floor surface and the floor slab with an insulating sheet. The heat from the hot water does not go through the usual radiator, but practically under the feet of the residents.

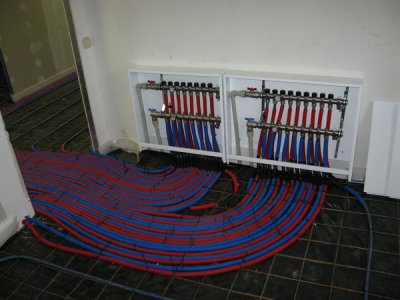

Photo 1. Installation of a water-heated floor: pipes are laid out around the entire perimeter of the room and connected to the heating source.

The circuit is connected to a gas boiler or central heating. The first option is preferable, since the quality of hot water in the central water supply directly depends on scheduled shutdowns, season and temperature changes. The gas boiler supplies uniform heat over the entire surface.

Pros and cons

As advantages warm floor It should be noted:

- uniform distribution of heat throughout the room;

- the air rises;

- the pipeline is hidden from view and does not disturb the aesthetics of the room;

- higher quality compared to other heating devices;

- low energy consumption (this is important for houses equipped with a meter);

- cooling the home in hot weather;

- low costs.

But this system also has peculiarities, which many consider to be disadvantages. The main one is pressure in the common water supply almost guaranteed will decrease. The water stream will become too thin, not only in everyday situations, but also in the case of connecting a hose to a pipe for extinguishing a fire. This point alone guarantees the discontent of neighbors.

Because of such innovations other apartments are deprived of heat. This contrast is especially noticeable in houses where several residents have already installed such heated floors.

To install this type of heating in an apartment, you need permission from supervisory authorities.

The project is ordered from a construction company and submitted to the Housing Department for approval.

Redevelopment must not disrupt the functioning of the communications of an apartment building (Resolution of the State Construction Committee No. 170 of September 27, 2003, Rules and regulations for the operation of housing stock, p. 1.7.2.).

Attention! ABOUT Find out if it is possible to install a warm water floor in your home in the management companyNot all buildings provide this option.

If you decide to install a heated floor structure, then It's better to contact a construction company. Specialists will carry out the work "turnkey": will assess the situation and prepare a project taking into account the specifics of your apartment. It is unlikely that a makeshift calculation will be approved.

Installation rules

Installation of underfloor heating consists of several stages.

Selecting a heating zone and designing a heated floor

Water heated floor Suitable for any premises: bedrooms, halls, offices. Most often it is found in private houses: in the rooms of an apartment building such a system cannot always be arranged, but in country houses there are no restrictions.

Main components of the heating system with heated floors:

- flooring;

- pipeline in cement screed;

- mixing unit.

It is better suited for the underfloor heating circuit metal-plastic or polyethylene. Products made from them are flexible and wear-resistant, retain heat well, and have a low level of resistance.

The mixing unit, designed to regulate temperature, includes:

- pump;

- collector;

- thermostatic mixer.

Important! Pressure and temperature standards: 10 bar, +100 degrees Celsius.

Having agreed on the issue with the necessary structures, you can begin to implement the plan.

Materials and equipment

For underfloor heating The following materials are needed:

- Pipes with a diameter of two centimeters made of reinforced polyethylene or metallized with corrosion protection. It is better to choose polyethylene, it is easier to work with them, the material is not subject to corrosion. To know exactly how many meters of pipe you will need, you should focus on the ratio - on 1 "square" have to 5 linear meters of pipes. The continuous length of the pipeline will be up to 120 m.

- Boiler for heating.

- Pressure pump (often included with the boiler).

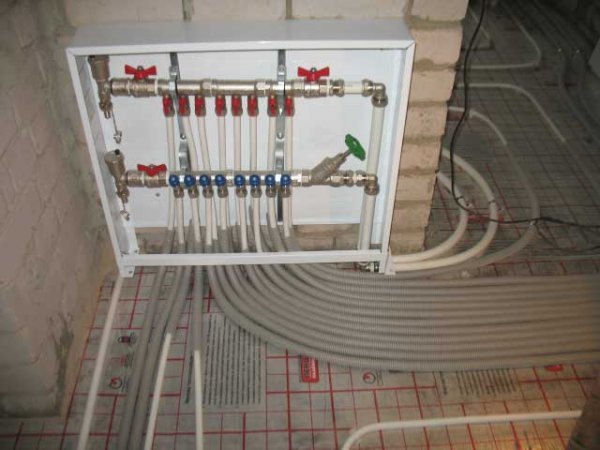

- Collector - looks like a pipe with a number of ports for connecting several circuits to the water intake and supply.

The composition includes two splitters, one distributes hot water along the circuit, and the second takes already cooled water. It is more convenient to buy a ready-made device, together with a wall cabinet. To do this, you need to know the total number of pipe inputs and outputs. The manifold is equipped with temperature regulators and pressure stabilizers, ports for connecting several heating devices.

Photo 2. Collector for underfloor heating system. Distributes hot water along the circuit and collects cooled water.

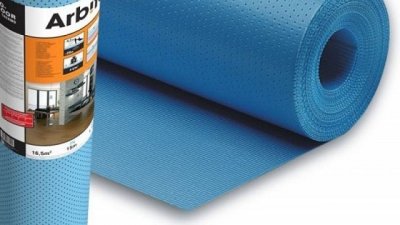

- Thermal insulation — this is polystyrene foam or any other heat-insulating material. Its area should exactly match the area of the heated room. Polystyrene foam is covered with a layer of waterproofing on top.

- Fittings for connection to the collector.

- Reinforced metal mesh for concrete screed (cell approx. 3 cm).

- Damper tape.

- Fasteners.

Important! If there is a stationary cabinet in the room, a section of the floor there is no insulation underneath it.

There are models with both single and multiple circuitsIf the second option is chosen, lay a damper tape.

Insulation of the base

To prevent the coating from giving off heat, take care to insulate the base. It all depends on what floor you live on:

- If your heated floor is an addition to the general house heating system, then you need to insulate the base foamed polyethylene sheet with a reflective foil layer.

- If your home is located not on the first floor, then to insulate the base you will need a polystyrene coating with a thickness of in 5 cm.

- If the apartment is located on the first floor, and the basement is not heated or does not have one at all, and then the soil begins, then one sheet will not be enough. To begin with, a mound of expanded clay is organized, on which polystyrene sheets are placed thickness up to 10 cm.

Reference. You can buy special insulation for heated floors.

To connect the heated floor, we invite you plumber, which will connect the pipes to the collector and workers from the construction company to lay the coating.

Laying and connection

All activities related to the installation of underfloor heating systems consists of several stages:

- leveling the floor surface for pipes - for this, self-leveling filler is used;

- installation of the collector on the wall - vertical, without errors, correctness is checked using a level;

- sticking on damper tape;

- laying a heat-insulating layer;

- installation of strips with locks if there are no fasteners for pipes.

Underfloor heating pipes are installed strictly according to the scheme. Then, using fittings, they are connected to the manifold. The manifold itself is connected to the water supply.

A test run is being made (for at least four hours): first at low temperature and pressure. Gradually they increase. If no leaks are observed, the pressure is increased to the maximum.

Next start pouring the heated floor. A mesh is laid on the pipes and concrete is poured in. The thickness of the layer is directly proportional to the system's capacity.

Important! Only buy the type of concrete that says on the label that it is Suitable for screeding water-based concrete floorsThe mixture is poured strictly from the edges to the center.

The screed is drying not less than a month. After drying, the system is tested again and the coating sheets are applied.

The thicker the layer of glue, the longer it takes to heat up.

Recommendations for installing water heated floors

During the work certain rules should be followed:

- When building a project warm floor take into account all the features of the room. To avoid errors, manufacturing companies use special regularly updated computer programs. Automated calculation allows achieving a flawless result, and this is another argument in favor of entrusting the work to professionals.

- To prevent concrete screed from cracking along the edges of the sheets of thermal insulation coating, its surface is covered with polyethylene film. You can glue the seams themselves with tape.

- Temperature regulating mechanism install away from the entrance door and sources of heat and light.

- Make sure that the prepared surface is perfectly flat. There are many ways to do this, in particular, a rough sand-concrete screed. Otherwise, the concrete layer hiding the pipes will lie unevenly, rising in one place and falling in another, which will affect the quality of the floor heating.

Suitable for screeding cement-sand or gypsum mixture, the main thing is that when pouring there are no bulges or holes.

Useful video

Watch the video, which talks about the features of installing a water-heated floor.

Is it worth taking on?

Assembling a heated floor is a complex task, for which it is not always possible to obtain permission. Before placing an order with a company, Consider all the pros and cons. If you are looking to save money, take on the installation work yourself, but have a qualified plumber connect to the water supply. Of course, the work will require effort, but in the end you will receive a priceless bonus - comfortable housing at any time of the year.

Comments