A worthy alternative to the traditional system: installation of a floor heating manifold

The collector is used for distributing the working fluid by heating system.

All devices included in the harness are connected to it.

The device is usually used in combination with heated floors.

Content

Purpose of the heating manifold

The main task of the collector is distribute water evenly through the pipes. This will allow all sections of the chain to heat up equally.

In some collector systems, the temperature increase occurs differently, which is due to the large number of connected devices.

Because of this, in the premises it's getting cooler. The collector helps to solve this problem.

Operating principle under the floor covering

The collector's work is as follows:

- hot coolant enters the device through the thermostat;

- he is met from the distributor a similar volume of cold liquid flow;

- cooled water is drained into the supply manifold, and some of it is returned to the circle for re-cooling;

- the mixture goes to the mixer and is distributed along the contour.

Before putting the collector into operation, it is necessary to carry out a thorough inspection. tuning and balancingThe first is done using flow meters, the second - by feeding liquid through a thermal head.

Types of mixing valves

The devices are found two types - two-way and three-way.

Two-way

Used in most collector systems. Such a tap allows manual regulation of coolant flows and pressure in the pipes. If necessary, the device simply maintains the set temperature. The valve also is responsible for feeding systems in case of water loss.

Photo 1. Two-way mixing valve for the manifold system, has the ability to maintain a set temperature.

The device is configured on the body and the heating level is set, which is regulated by the built-in or remotely. In the latter case, a sensor is installed on the input part. Operation of the two-way device is as follows:

- The working fluid leaves the return circuit of the heated floors, then begins to circulate through the harness.

- If cooling of water is detected, part of it enters the collector and mixed with the hot water stored in the device.

- The heated mixture leaves the device, the rod closes, and the coolant is sent to the boiler.

Important! Such cranes are used in buildings if the area of the piping is less than 200 sq. m. In other cases, the temperature decreases because the water cools down as it moves. This leads to high fuel consumption due to the need for constant heating of the coolant. To solve this problem, it is necessary to split the system into several circuits.

Three types of mixer

Two-way mixers separate into three types:

- pneumatic;

- electrical;

- hydraulic.

The first are triggered mechanically, second — by electric drive, and third — by water pressure and temperature. Manufacturers make taps made of cast iron or brass.

They are built into the design 1-2 saddles, and the latter option is used when it is necessary to completely block the flow.

Operating principle of the devices:

- The impact on the drive is transmitted to the valve assembly, which includes a seat and a plunger.

- The latter begins to move, blocking the internal volume. This increases the flow of working fluid and reduces the system pressure.

- When it's all the way down, the tap is hermetically sealed, which leads to a stop in the flow of water.

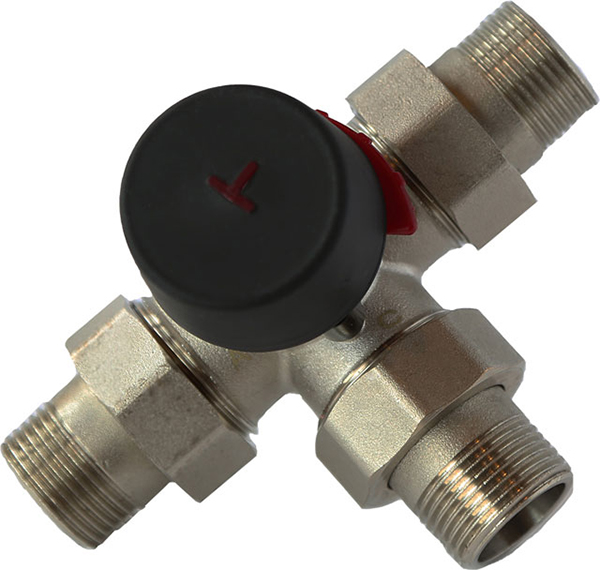

Three-way

Serves for uninterrupted operation of warm floors in heating. Shut-off valves mixes streams: hot from the heater and cold from the harness. The device is quite versatile, but has two drawbacks:

- Upon receiving the signal, the tap opens fully. Boiling water mixes with cooled water, but due to the width of the flow, overheating of the piping may occur. In extreme cases, the pipe will rupture.

- Unlike a two-way valve, this one has a higher flow capacity, which results in a wave-like change in temperature. This increases the heating range. The valve allows heating of rooms with an area of more than 200 square meters.

Manufacturers use bronze or brass. A washer is placed in the upper part of the tap. It serves for regulation. A thermal head is placed under it, which reacts to the heating or cooling of the coolant. During operation, the device is pressed against the rod. The latter has a built-in cone adjacent to the saddle.

Photo 2. Three-way mixing valve, made of bronze, equipped with a washer at the top of the device.

Water flows through the pipes until the set level is established. Liquids of different temperatures are mixed, until the owner has set it up. When the latter is changed, the drive acts on the rod. The built-in cone moves away from the seat, opening the channels. After changing the readings, the front pipe closes.

Four types of three-way valves

They highlight 4 types three-way valves:

- With thermostatic drive. The device acts on the rod as the water expands due to heating. Most taps are equipped with this mechanism if the manifold is used for heated floors. Otherwise, other options are considered.

Photo 3. Three-way Valtec valve with thermostatic actuator, suitable for most valves in which the manifold is used for heated floors.

- With a thermal head including a sensitive element. The latter reacts to temperature changes and begins to regulate the supply of working fluid. The device operates until the set reading is obtained.

Attention! Measurements are taken automatically using a sensor installed in the pipeline. This type of valve has high precision.

- With an electric drive, controlled by a controller. The latter constantly receives data from devices located in the piping. When the temperature changes, a signal is sent to the servo drive. It begins to regulate the heating of the coolant, mixing boiling water from the boiler with cooled liquid from the circuit.

- With servo drive, but without controller. A similar mechanism directly affects the tap, receiving a signal from the meters. The circuit uses valves with ball or sector distributors.

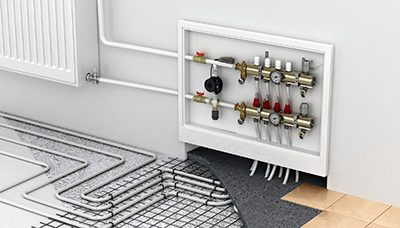

The principle of the arrangement of the device for underfloor heating

In apartment buildings such a system do not install. When installing in a private building, the following points are taken into account:

- Space is required for an expansion tank, circulation pump and individual piping layout. The first is placed in the circuit before the second.

- It is necessary to develop a design, location and number of pipes.

- Installation is carried out in a room with low humidity.

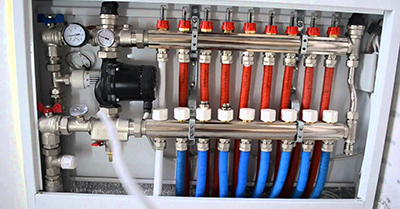

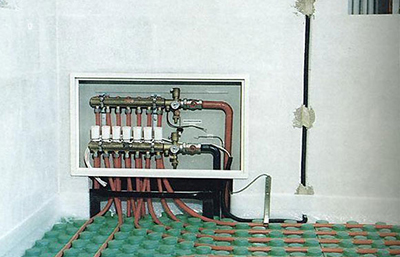

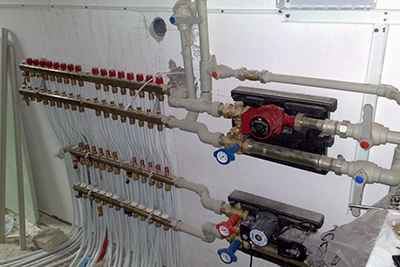

- Most collectors are placed in special cabinets., if there is space for them. Otherwise, they are simply installed on the wall.

Selecting a device

Depends from three indicators: the main component of the device, the number of circuits and the required functions of the device.

Material

First you need to think about the main parameters, make calculations, and then choose from three options:

- stainless steel;

- brass;

- plastic.

The first is a high-quality, durable and long-lasting, but expensive material. Brass is more fragile, although it is much cheaper. Plastic has characteristics similar to the previous option, although the quality product is stronger.

Reference! The choice of device partly depends on the manufacturer. High-quality devices cost quite a lot, but at the same time reliable.

Number of connected circuits

To make the calculations, you need to draw up a system design. Number of slots - sum of branches of the chain, coming from the collector. It is enough to add up the number of rooms in which it is planned to use warm floors, add radiator circuits, if their connection is provided.

Main parameters and additional functions

The collector must perform the following tasks:

- Distribute the coolant through the pipes.

- Monitor system pressure and temperature.

- Have manual adjustment.

They are built into expensive devices extended functionality. For example, automatic change of fuel consumption, remote control, etc.

Installation

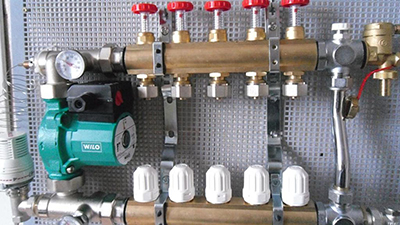

The general principle of installation of the device is as follows:

- A load-bearing element is attached to the wall.

- To him screw on the distributors.

- To the last connect sensors, valves and regulators.

- They create the harness and wiring.

- Connecting pipes.

- Installing a circulation pump, servo drive, thermal head, heating element.

- They are doing a test run.

Installation of the manifold cabinet

The base of the device is placed in any convenient place. The only rule is it must be dry.

The fittings are fixed in a special cabinet, which is mounted on a vertical surface. If it is not used, then simply on the wall.

Height should be small, about a meter and a half.

Assembly

The profile is marked in the body. The gas cutter makes holes for the pipes. Small pieces of the latter are inserted into the prepared places and secured, subsequently The harness is connected to the parts. Then The fasteners are installed, the device is cleaned and painted. The base is mounted in a cabinet or on a wall.

Connection via polypropylene pipes

It is done by simple welding with point welding. It is better to invite an experienced specialist to get a quality result.

Installation of metal-plastic pipes

It consists of the following:

- First, the edging of the trim parts is done.

- The installation depth of the part is marked.

- A special nut is put on with the thread towards the edge, secure with a retaining ring, then tighten onto the manifold fitting.

Fastening

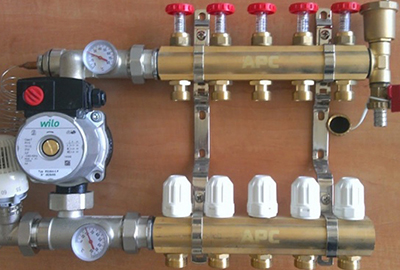

All elements in turn are attached to the structure. First expansion tank, then circulation pump. They are mounting valves, thermostatic head, heating boiler. If there is, they install automation or a remote control system.

Assembly of the mixing unit

The feed part must be higher than the return part, otherwise efficiency drops. The first one also has flow meters and servo drives, working fluid drain and air bleed valves. Then They install connecting fittings and mount them in the cabinet.

Useful video

After watching the video, you can learn from a specialist about some of the nuances of installing a manifold for underfloor heating.

Conclusion

A collector is a useful device that should be installed if capital allowsIt is better to choose a more expensive but reliable option.