How to easily connect a water-heated floor to the heating system?

Water heated floor - effective, and most importantly economical heating method. With it, rooms are heated evenly, without "warm" and "cool" zones.

There is no need to talk about the convenience of its use at all - it is a pleasure to walk barefoot. But due to the permit system, installation features, It is used more in private houses, and much less frequently in apartments.

Content

The principle of connecting a water-heated floor in a house

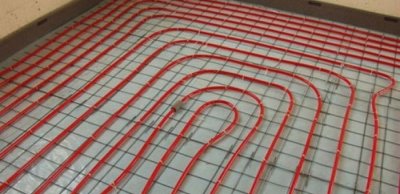

"Heating element" - a pipe, mounted in two main ways:

- Into the solutionMore often, on a concrete subfloor it is filled with a screed.

- On dry surfacesUsually, a pipe is laid into the grooves on a wooden subfloor and covered with floor coverings.

The optimal material is metal-plastic or polyethylene, but there are also “elite grades”: corrugated stainless steel, and copper with polyethylene insulation.

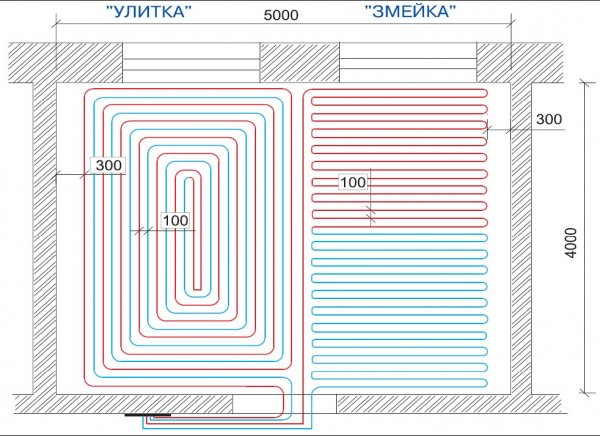

The pipe is laid out into a contour in two main ways: snail and snake, This can immediately ensure uniformity or set priority areas for heating the floor.

Photo 1. On the left is a diagram of the installation of a "snail" type of warm water floor, on the right is a "snake" type.

When connecting a warm floor to an existing system, it is necessary to take into account that circuits, unlike radiators, require a lower temperature of the coolant during intensive heating mode. A comfortable temperature regime is achieved due to:

- use coolant, which has already given off most of its heat;

- installations thermostat valve, limiting the supply of coolant;

- admixtures in hot, as cool as possible coolant.

Therefore, when planning the installation of a heated floor, it is important to consider the principles of connection to various types of existing heating systems.

To an existing one-pipe heating system, as a radiator

It is possible to connect a small underfloor heating circuit to a single-pipe Leningradka additional radiator.

Preferably in series with the installed battery, but if there is no technical possibility, then in parallel with the battery, it is important to do this through valves in order to be able to “press” or completely disconnect it.

The semi-automatic mode of operation of the circuits is set initially if simple conditions are met:

- The heated floor takes the coolant from return lines heating, where the temperature is lower - during intensive heating, full power is not needed. It is connected AFTER the circulation pump before the boiler, and returns the coolant BEFORE the same pump - forced circulation occurs.

- The contours do not exceed 30 meters long, This will ensure full heating at reduced heating intensity.

How to connect to a two-pipe system

Connecting a heated floor to a two-pipe system is possible using any method for a one-pipe system.

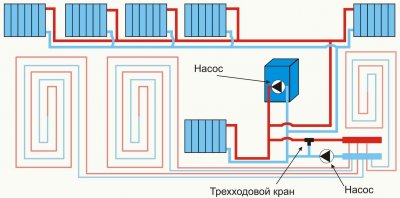

The heated areas will increase significantly if the circuits are control module connect directly to the supply and return pipes of the radiator heating system.

This is the best option when heating is needed for several rooms at once, since each of them requires, at least one circuit.

How to connect to an existing gravity circuit

There is a persistent opinion that underfloor heating circuits work poorly or do not work at all in pumpless heating systems, where the coolant circulates by gravity, due to convection. But practice shows successful operation under simple conditions:

- Please note that pipelines - "beds" convection systems are always mounted not strictly horizontally, but with a slight slope from the feed to the return. It is advisable to take advantage of this and make cuts in the "bed" so that the coolant flows downhill. Therefore, the return lines of the underfloor heating circuits are often combined into one comb at a distance from the heated rooms.

- Subfloor — the base on which the underfloor heating pipe is laid must be strictly horizontal and as level as possible — so that there are no “gravitational” obstacles to movement, and the liquid does not have to flow “uphill”.

- Contours - "snails, snakes" if possible as short as possible - only the necessary areas are heated.

- Pipe diameter 20-25 mm - fixed without jumps, humps and differences, tightly pressed to the base, eliminating the formation of air locks.

- All turns smooth.

The main disadvantage is that heating is slower, but convection systems themselves inert, this is the price to pay for the lack of a circulation pump and independence from electricity.

Important! Most often, for convection heating systems, the main pipelines-beds are made of metal, therefore "cut-ins" will be the elbows. It is better to weld them not at a right angle, but “along the flow” of the pipe, both on the feed and return.

Combined scheme for an apartment

The vast majority of well-appointed apartments are designed exclusively with radiator heating.

By connecting several or at least one common underfloor heating circuit to it, the level of comfort increases. many times.

Is it worth talking about the need for underfloor heating in bathrooms or at the entrance door in the hallway - this is the necessary minimum, you will find a couple more places, where warmth would not be a problem.

As with any combined scheme, to reduce the temperature of the coolant, the underfloor heating circuit is connected to the return line, through taps and a pump-mixing unit. Collectors are needed if there are several circuits.

Attention! All this is overshadowed prohibition of housing and communal services from unauthorized interference, changing the heating system of an apartment building, and threatens sanctions.

However, it is possible to legalize it - to obtain permission to install additional heating devices, but compelling reasons are needed and the tariffs for payment will be recalculated.

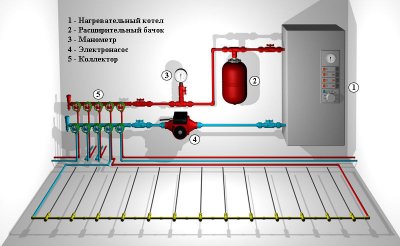

To the heating boiler

It happens that a house is installed “for the future” double-circuit boiler, but hot water supply was implemented using an electric water heater, and the second circuit was never used to heat tap water.

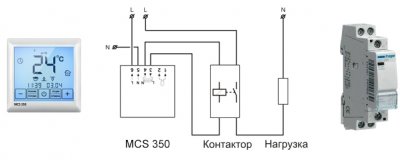

It is possible to install an independent low-temperature underfloor heating system on its basis. Of course, you can't do without control system and pump.

Operating principle: the pump pumps the coolant, the movement of the liquid starts it second circuit, Upon reaching the set temperature, heating stops, as the control system cuts off the heat carrier from the boiler and loops around the underfloor heating circuit without heating. Having given off heat, the control system switches back to heating.

Despite its apparent complexity, the system is highly stable and reliable, as it operates in low-temperature conditions.

Conditions for connection to batteries

It is obvious that the comfort of the house is significantly increased by supplementing the radiator heating with a warm floor system. But in most cases it is impossible to limit oneself to simple "cut-in" into the current system, for a high-quality connection it will be necessary to install additional equipment in order to meet a number of conditions for stable operation:

- provide circulation, in long and thin pipes the gravity flow of the coolant is difficult or impossible;

- prevent water hammer, equalizing the pressure in the supply and return pipelines;

- automatically remove air from the underfloor heating system;

- filter coolant, especially relevant when connecting to a central heating system;

- reduce the temperature of the coolant, to optimal, for a comfortable microclimate in the premises.

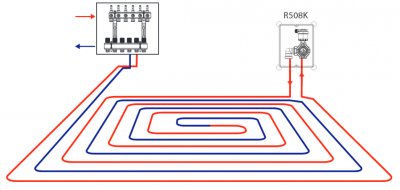

Therefore, the system is supplemented with equipment, which is usually concentrated in one place for ease of management.

Reference! For universality of connection it is generally combined into single modules, They can be purchased ready-made, factory-made and with the required parameters.

Connection module device

The task of the module: to eliminate overheating, reduce the temperature, and ensure uninterrupted circulation of the coolant.

Main components:

- circulation pump;

- relief valve;

- air vent;

- filter;

- mixer;

- shut-off valves.

The module is connected directly to the collectors, and to them - the underfloor heating circuits. Control is possible in manual, automatic and programmable modes, depending on the configuration.

Unfortunately, you have to pay extra for versatility, so self-assembly of modules from individual components is also practiced. based on three-way thermostatic valves, having decent characteristics:

- temperature accuracy from 1 to 2°C, in the working range from 25 to 50°C;

- between return and prepared - mixed water permanent bypass;

- internal teflon coating to reduce hard water deposits;

- own protection from overheating;

- built-in mesh filters;

- fastening in any position.

The area of heated floors depends on the power of the selected pump.

Useful video

Check out the video that shows how to connect a heated floor system to a boiler.

With your own hands - and without consequences

There is nothing supernatural in connecting a warm floor to a ready-made, operating heating system. Preparation, installation, even the most important and expensive components it is possible to do it yourself, if desired, an inquisitive mind and skillful hands will do the job. But this does not mean that you should give up consultations and services of specialists, especially in apartment buildings.