The right choice of these products will not allow you to freeze! Which heating pipes are best for an apartment

There is a wide range of materials for heating distribution in an apartment. All of them are divided into two large groups: metals and plastics.

From the right choice The heating pipes will determine how efficiently the room is heated, the frequency of replacement of products and the frequency of repair of the heating system.

Content

Features of choosing pipes for heating in an apartment of a multi-storey building

Material for installation of heating system are chosen based on the following considerations:

- reliability and safety;

- ease of installation;

- location in the apartment;

- cost of materials and installation work.

Reliability and safety

These are the main criteria for selection: the material is one of the important characteristics that influences the stable operation of the heating system without the occurrence of emergency situations.

Reasons why accidents may occur:

- Destruction of the material under the influence of temperature and pressure of the coolant in the system.

- Leakage in connections.

From a security perspective, The most reliable is considered to be a metal heating pipeline. All parts and units made of such materials withstand the temperature and pressure of the coolant in the system with a reserve. In the settlements of the Far North, metal pipes are the only and non-alternative option for central heating.

An important factor in favor of this material is that failure of system elements (for example, due to corrosion) occurs gradually and can be detected in a timely manner, and the problems are eliminated without much damage to the apartment owner. For example, if a metal product leaks due to a fistula, it can be temporarily closed with a clamp.

Attention! A plastic pipeline does not have this capability if it is destroyed. the consequences will be more dire.

Breakdowns of plastic structures occur in the following situations:

- when installing counterfeit products (fakes);

- if the characteristics of the material do not correspond to the temperature and pressure values in the system;

- if installation technology is not followed.

It is important to remember:

- To avoid buying fakes, you should only buy the material from official dealers of the manufacturer.

- Products must be certified and are designed for the existing temperature and pressure in the system.

- Installation should be carried out in accordance with the official installation manual (which is available on the website of the system manufacturer).

Ease of installation

In terms of speed and ease of installation, plastic pipelines are unrivaled, as they do not require any specific professional qualifications. quick and easy to install, require a minimum of tools for assembly.

Installation of metal systems is less convenient, since more It is time-consuming, labor-intensive, and requires a highly qualified welder.

The best option for installation is polypropylene. The installation tool kit (welding machine) is inexpensive and can be rented. While the tool for fastening press fittings to metal-plastic has a higher cost.

Place in the interior

Heating pipes in an apartment are always hidden, as they spoil the interior appearance and can interfere with installing or moving furniture. can be hidden in walls or laid in floor screed.

If a decision is made to install a hidden heating system, then the design should be selected made of plastic materials, which can and should be hidden in walls or floors, as they are destroyed by ultraviolet radiation contained in sunlight.

It is important to take into account that all hidden connections must be non-separable (metal-plastic should be connected with press fittings, not compression fittings with a union nut).

Steel products in terms of hidden wiring, they are very inferior to polymeric materials. To bend a steel pipe to fit it into a groove, you need to apply a lot of effort, so such products are usually laid openly. They look unpresentable.

Copper and stainless steel in appearance, they win over steel ones. They are also laid in an open way, but, unlike steel products, they look better in the interior. Such pipelines are usually not hidden in walls or floors; for this purpose, there are cheaper options made of polymer materials.

Cost of materials and installation works

The most economical are systems made of polypropylene - they are inexpensive, installation costs are low, since installation is carried out quickly.

Slightly higher in cost is the heating system made of black steel. Material price comparable to polypropylene, however, due to the high labor intensity of the work, the total cost of the system will be higher than that of polypropylene.

Systems made of metal-plastic and cross-linked polyethylene are in the middle price category.

The most expensive options are copper and stainless steel. The price of materials exceeds 2-3 times cost of polypropylene, installation is also not cheap. This option is usually chosen to implement design solutions.

Metal pipes: which type is better to use

Pipes can be made from materials such as:

- ferrous metal (steel);

- copper;

- stainless steel.

Metal products are characterized by high strength, reliability and durability.

Black metal

As a rule, black steel pipes without coating are used in heating. It is useless to use galvanized steel - at a temperature more than 70º the coating inside will not hold (galvanizing is used for cold water supply).

Steel structures are classified according to the manufacturing method electric-welded and solid-rolled (they have the same corrosion resistance and strength).

Photo 1. Heating pipes made of black metal. This type of product does not always match the interior.

Pipes differ in their internal nominal diameter (DN). DN 15 mm True to size ½ inch, DU 20 mm True to size ¾ inch.

The wall thickness of steel products for heating must be 2.8 mm or 3.2 mm. When buying, you need to choose products of Russian manufacture, manufactured according to GOST, with a certificate of conformity. There is a lot of low-quality material from China on the market with an unknown steel composition and thin walls.

Good steel heating pipe virtually corrosion-resistant due to the lack of oxygen in the coolant.

It is recommended to connect such products using the method gas or electric welding.

Stainless steel

Heating systems made of stainless steel are characterized by high strength, reliability, corrosion resistance, and ease of installation. The disadvantage is high cost of material, fittings and special tools.

There are two types of stainless steel heating pipe structures:

- rigid straight with press fitting systems;

- flexible corrugated with threaded or compression fitting systems.

When choosing stainless steel products, preference should be given to rigid straight pipes with press fitting systems, which are available, for example, at VALTEC.

Photo 2. Stainless steel pipes for heating systems. The products are connected to heating radiators.

It is not recommended to use flexible corrugated pipes in apartments:

- The profile of the structure creates increased resistance for the coolant, which is why the pipes make noise.

- They are not convenient for hidden installation (access to threaded fittings is required).

Copper

Copper pipes are rigid, in the form of straight sections, and soft, in the form of a coil. For open installation in a heating system, they are usually used, rigid pipe with increased wall thickness. Soft pipes, due to their curvature, do not decorate the room - they are used, for example, to supply fuel to boiler rooms of private houses.

Features of rigid copper pipe:

- High strength and temperature resistance.

- Aesthetic appearance.

- High thermal conductivity - can be used in design instead of radiators.

Photo 3. Copper pipes for heating an apartment, connected to radiators. They are considered one of the most effective designs.

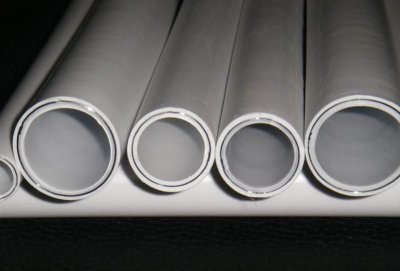

Plastic products

The main material of the pipe is plastic - polypropylene or cross-linked polyethylene.

Properties of plastic:

- Chemical inertness - does not react with the coolant, does not oxidize, does not corrode.

- Lightweight and easy to lay due to its flexibility.

Polypropylene

For heating, reinforced PP is used, the design of which has an aluminum insert. As a rule, those types are used whose working pressure is not lower than for PN25 types.

Features of reinforced PP:

- mechanical strength due to the aluminum insert;

- possibility of hidden installation;

- ease of installation.

Important! When installing, please observe temperature conditions, so as not to overheat the connection.

Cross-linked polyethylene

Cross-linked polyethylene (PEX) is a material that has been specially treated to improve its mechanical strength and temperature resistance.

The characteristics of PEX products are inferior to polypropylene in terms of resistance to working pressure, which 90ºС amounts to only 0.8 MPa (for polypropylene - 10 MPa).

It is better not to use PEX pipes in apartments. This material is used when installing heated floors in private homes.

Metal-plastic

The pipe consists of two layers of PEX-polyethylene, separated by an aluminum insert 0.4 mm thick.

When choosing an MP pipe, you should check on the manufacturer's website whether it is suitable for temperature and pressure for central heating.

Metal-plastic are assembled using press fittings.

This system allows for hidden installation, while being sufficiently reliable, durable and long-lasting.

Useful video

Watch the video, which tells how to choose plastic pipes for the heating system.

Optimal choice

Metal pipes are used in heating systems where resistance to temperatures and pressure of the coolant is required. The optimal choice of material for wiring in an apartment is reinforced PP.

Comments

But we were warned that they should not be near open fire.

The price matches the quality, in my opinion.