Advantages of cross-linked polyethylene for heating over other materials. Installation features

Cross-linked polyethylene - innovative material for the production of pipes. Unlike conventional PE, it can withstand high pressure, chemical reagents, and hot water.

It is used for cold and hot water supply and heating pipelines.

Installation of PEX pipes is not difficult, but has some special features, knowledge of which will help to perform the installation correctly.

Content

Pipes for heating and water supply systems made of cross-linked polyethylene

The new material shows properties of metals and polymers. Cross-linked polyethylene is a thermoplastic polymer with a three-dimensional structure.

Cross-linking technology creates intermolecular network, similar to the crystal lattice of substances in the solid state.

Thanks to this, flexibility is maintained, the melting temperature increases, resistance to thermal deformations, scratches, cracks is increased. The material is designated PEX (PEX), where X stands for crosslinking.

Application in residential buildings

Cross-linked polyethylene is used for laying pipelines external and internal engineering systems residential buildings: heating, sewerage, hot and cold water supply.

Main areas of application:

- Warm floor.

- Heating systems, working with coolants at low temperatures.

- Intra-apartment water supply.

Photo 1. Installation of warm water floors with red cross-linked polyethylene pipes indoors.

- Heating with horizontal distribution.

- Gutters.

Important! Molecularly modified polyethylene is environmentally friendly and safe: it does not emit toxic substances, therefore it is used for residential premises. When burning, it decomposes into compounds that are harmless to humans: carbon dioxide and water.

Technical properties

- Combustion temperature – 400° C.

- Melting - starts at 200° C.

- Average density – 940 kg/m3.

- Elongation without breaking - in the range 350–800%.

- Maintaining characteristics at temperature up to –50° C.

- Thermal conductivity – 0.38 W/mK.

- Flexibility.

When operating under standard conditions (coolant temperature within 75° C) cross-linked polyethylene will last about 50 years. With constant use under extreme loads: increased pressure, 95-degree coolant the service life will be reduced to 15 years old.

Sizes and diameters

PEX pipes are available in diameters 10–280 mm and wall thickness 1.7–29.0 mm. Supplied in coils in sections 6, 8, 10, 12 meters.

According to the degree of pressure resistance, cross-linked polyethylene pipes are divided into the following types:

- light: 0.25 MPa (2.5 atm);

- medium light: 0.4 MPa (4 atm);

- average: 0.6 MPa (6 atm);

- heavy: 1 MPa (10 atm).

The pressure indicated above is conditional, the data is valid when pumping water t 20° C.

Advantages and disadvantages

Polyethylene, cross-linked at the molecular level, retains positive qualities of standard PE and acquires new advantages:

- Molecular memory – in case of deformations and bends, the shape is completely restored.

- Absence of scale, mineral and biological formations – the pipes have a smooth inner surface.

- High density of connections – no additional seals required.

- Impact resistance, cracking at temperatures up to –50° C.

- Flexibility – do not break when bent repeatedly.

- Chemical resistance – pipes do not react with alkalis, acids, organic solvents.

- Ecological cleanliness – pipes are certified for drinking water.

- Resistant to hot water under pressure.

The disadvantages of cross-linked PE pipes include: sensitivity to UV radiation and slow destruction under the influence of free oxygen penetrating the structure from the air.

Attention! To prevent unwanted contact of PEX pipes with air, it is used anti-diffusion protection. Such a coating should be handled carefully so as not to scratch it during installation or transportation. The products are protected from ultraviolet radiation. special additives, which are included in the composition at the production stage.

Types of PEXАУ pipes

- Universal – equally suitable for use in different areas: for installing water floors, hot and cold water supply systems, autonomous and central heating.

Photo 2. Universal polyethylene pipe Rehau Pautitan flex, suitable for any type of heating.

- Specialized – have a narrow scope of application. They are intended for a specific type of pipelines, for example, only for cold water supply or individual heating.

Depending on the conditions of use, water or antifreeze liquids are used in cross-linked polyethylene heating pipes.

In standard mode, heating pipes operate at maximum temperature up to 95° C and pressure up to 10 atmIn an emergency, they can withstand temperature fluctuations. up to 110° C with a twofold increase in pressure.

Types of pipes from the leading manufacturer Uponor

The company Uponor (Finland) produces pipes four types:

- Aqua Pipe – for hot and cold water supply.

- Comfort Pipe Plus, Radi Pipe – for underfloor radiator heating, cooling systems.

- Combi Pipe - universal.

- Comfort Pipe – for underfloor heating systems.

Photo 3. Uponor Comfort Pipe cross-linked polyethylene pipes are designed for underfloor heating.

Size range of cross-linked polyethylene products 15–110 mm. Supplied in coils 50–540 meters, In 6-meter sections.

The German company REHAU produces a wide range of pipes of the series RAUTITAN:

- FLEX – are flexible and are used for cold and hot water supply, floor and radiator heating of residential premises.

- STABIL – universal, have an internal aluminum layer.

- HIS - universal use in temperature conditions up to 70° C up to 10 atm.

- PINK – for underfloor heating, radiator wiring in residential and public buildings.

Connection - fittings with sliding sleeve, size range 12–250 mm. Pipes are supplied in straight lengths. 6 m each or in coils of 25–125 meters.

Installation

There are three ways to connect PEX elements:

- Compression fittings - suitable for water supply (cold and hot). If necessary, the water supply can be dismantled at any time.

- Press fittings – a permanent connection is obtained. The method is based on the ability of cross-linked polyethylene to recreate its shape.

- Electrofusion fittings – the strongest and most reliable connection. The method requires skills in working with welding equipment.

Attention! When choosing a method of installation, consider the pressure that will be in the system. Compression fittings can withstand up to 2.5 atm, press fittings – up to 6 atm, electric welded – provide a monolithic connection.

Tools

Depending on the installation method you choose, you will need:

- set of fittings;

- special scissors (manual pipe cutter);

- expanders of the required diameters;

- set of wrenches, pliers;

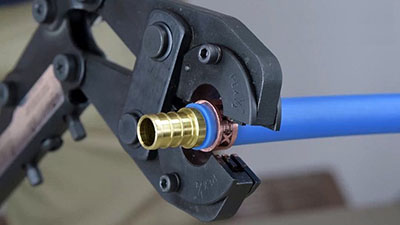

- hydraulic or manual press – for press fittings;

- welding device – for electrofusion couplings.

Electrofusion couplings – a type of fitting in the form of a sleeve with built-in heating terminals.

Reference! Fittings are connecting elements of a pipeline, used for assembly and joining, branching, and turning pipes. Main material: brass, but polyethylene, polyvinyl chloride, polypropylene, and combined parts are also produced.

Preparatory work

Before starting installation, ensure that the work area is clean - in the connection areas dust and dirt should not penetrate.

Using the radiator connection diagram as a guide, prepare the required number of fittings and pipes. Cross-linked polyethylene is flexible, so secure the pipes to the wall using brackets.

Check it out collector outputs - they must be in good condition. To avoid condensation on the "cold" system and heat loss from hot water pipes, prepare additional thermal insulation.

Operating rules and connection to the radiator

- A high-quality cut is the key to a tight joint. Cut the pipe strictly at 90° – perpendicular to the horizontal axis.

- Make sure that the cut surface is absolutely flat. – without cuts, roughness, waves.

- For connections, select only specialized fittings – for cross-linked polyethylene.

- If a pipe bend is required, first Heat the area to be bent with a hair dryer.

- When using the electric welding method Monitor the temperature of the device. Cross-linked polyethylene can overheat and burn.

- For high-quality installation Follow the pipe and fitting manufacturer's instructions.

Compression method

- Cut the pipe, Place a compression nut on the cut. The thread should face the connector.

- Put on the split ring, fix it in 1 millimeter from the pipe cut.

- Insert the fitting into the pipe. Pull the end with the ring and compression nut onto the fitting until it stops.

- Move the nut and tighten securely using wrenches.

The compression nut is tightened until it stops, but it can't be pulled too far — the thread on the fitting may be damaged.

Using press fittings

- Place a press sleeve on the end of the pipe, made in the form of a ring.

- Insert an expander of the required diameter into the pipe, pull the handles all the way and hold them 2–5 seconds. Increase the diameter until the end fits over the nipple of the fitting.

- Insert the fitting into the prepared pipe – the fitting is inserted until it stops.

- Place the press sleeve on top. Due to the molecular shape memory property of cross-linked polyethylene, after a few minutes the stretched section will return to its original diameter and tightly grip the fitting.

Electric welding method

- Put it on the end of the pipe electrofusion coupling.

- Connect the electric welding device to the terminals of the fitting.

- During welding, voltage is supplied from the device to the inside of the coupling. The unit (fitting and cross-linked polyethylene) is heated to the melting temperature (170° C and more).

- Turn off the welding machine, wait until the connection cools down. A properly assembled unit will withstand up to 12 atm pressure.

Useful video

In the video you can see how the installation of heating pipes made of cross-linked polyethylene with a side connection of the battery is carried out.

The final stage is checking for leaks

After assembling the water supply system, underfloor heating, heating circuit, be sure to carry out hydraulic tests (pressure testing). Fill the system with water, remove air, set the pressure 1.5 times superior to work, not less than 6 atm. Maintain this value. 30 minutes.

Then quickly lower the pressure to half the working norm. If after this the value increases - the communication from cross-linked polyethylene is hermetic. Leave the system with pressure 50% of the working day for 1.5 hours, if the value decreases during this time, then there is a leak.