Delivers heat to all corners of the house! Brick stove with a water circuit: features, row by row

Water circuit - this is the supply of water to heating devices after heating in the stove. This system is an analogue of a solid fuel boiler, it is often used as an alternative heating method.

In the case of a brick oven, the water circuit complements the building's heating system using wood.

This profitable in the event of a sudden shutdown of central gas heating in residential areas, exceeding 100 sq. m.

The main element that heats the water is the heat exchanger, also called water jacket, coil, register or even a boiler. The heat carrier — water — passes through it and heats up, which then enters the system of pipes and radiators distributed throughout the house. The water moves through the heating elements on its own or under the action of a pump. In the latter case, the heat is distributed more evenly.

Content

Design options for brick ovens with a heating circuit

The type of stove with a water circuit that is installed in the house is chosen taking into account a number of conditions. These include:

- presence of another OS;

- area of the premises;

- season of residence.

Photo 1. Construction of a brick oven with a water circuit. A heat exchanger made of pipes is mounted inside.

If the house already has a heating system (HS), It is necessary to integrate the stove option as an alternative while maintaining the existing communications layout. The area of the room directly affects the efficiency of heating, so it makes sense to think about a stove that can retain heat well, and also take care of the layout that delivers it to remote areas of the building. The season of residence allows you to understand whether to make a structure for the whole year or only for the cold season.

An important part of the entire system is installed in the firebox of a brick oven - heat exchanger. It can have different designs. Existing diagrams and drawings offer several common options - from pipes, sheet steel and batteries.

Heat exchanger made of pipes

The first option is based on metal pipes, welded into a rectangular structure. It is usually smaller in size than the firebox of a brick oven and is installed at some distance from the walls. This is necessary for the metal to expand when heated. The shape of the heat exchanger tubes diameter up to 50 mm allows the water flowing through them to be well heated. The key feature of this option is that if one of the tubes fails, it can be easily replaced.

Heat exchanger made of steel sheets

The sheet steel heat exchanger uses pipes instead of pipes. water-filled chambers.

Photo 2. Heat exchanger for a brick oven, made of steel sheets. Pipes for hot and cold water are installed on both sides.

Unlike the pipe version, the sheet tank area is larger, which means that the heat transfer to the liquid flowing through it is higher, but the service life is shorter. At the same time, in both versions with similar dimensions 36x40x80 cm Necessarily two more pipes are used: to the hot water outlet from above and to the return inlet from below.

Water jacket from a battery

There is another option - heat exchanger from an old battery. Several cast iron sections are quite capable of providing heat to the heating system.. The advantage of this approach - no costs for manufacturing and materials.

However, there is a downside — large sections that will have to be placed not in the firebox, but in a separate section of the brick oven. Heat is supplied to it through a separate channel in the masonry. Considering the thickness of the battery wall (about 3 mm), no direct contact with fire will not have the best effect on efficiency. And the large weight will require a solid foundation.

Photo 3. Heat exchanger for a brick oven, made from an old cast iron battery. The structure is not installed in the firebox.

How to choose a project? Ordering

First of all, decide on the conditions in which the furnace with a water circuit will operate. If this is integration into an existing OS, it is important to ensure interchangeability in the operation of existing communications. For an independent option, it is important to determine the area that the system will heat. For 100 square meters For a one-story house, a regular stove will be enough.

It's a different matter if the area, number of rooms and floors is larger. Finally, it's important to understand, will the OS be used all year round or only during cold weatherIf the house is lived in during the summer and is idle during the winter, then after the cold and frost the system will require restoration work, which will entail additional costs.

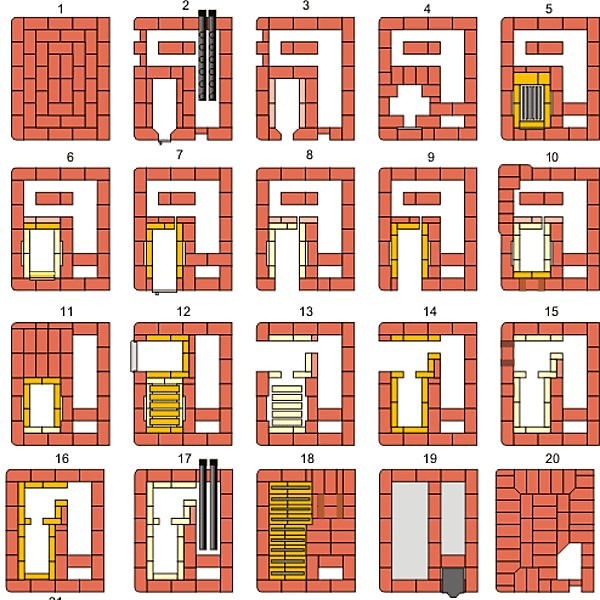

Photo 4. An example of the order of a brick oven with a water circuit: the initial stages of construction from 1 to 20 are shown.

What materials will be required?

For the stove itself: concrete, mortar, firebrick and red clay brick, valves, firebox door, grate, ash pan.

For the manufacture of a heat exchanger: metal pipes with a diameter up to 50 mm or steel sheets 3mm thick and rectangular profile 60x40 mm.

For the production of outlet and inlet communications of the furnace: metal pipes. To distribute hot water throughout the house: Polypropylene pipes and radiators.

Necessary tools

For laying the stove, manufacturing the heat exchanger, installing communications and heating devices you will need:

- building level;

- roulette;

- trowel;

- bucket;

- pliers;

- electric drill;

- welding inverter;

- spanner;

- screwdriver.

Other tools may be required., since the laying of the stove with a water circuit and the layout in each case are carried out taking into account individual conditions.

Preparing the site

Furnace with water circuit located in a fire-safe zone, which has waterproofing.

This area of the room should be well ventilated, and always leave access to the stove open. Then make sure that the space for the stove even, and its walls will rise upward at a right angle.

It is important that the roof allowed the pipe to be brought out without any obstacles. Then check how much solid foundation under the future structure.

After all, a stove is a heavy structure that requires a prepared base. The approximate weight of a stove is calculated by equating 1 cubic meter to 1350 kgOnce a suitable site has been identified, it is cleared and prepared for the construction process.

Attention! To achieve maximum effect, the stove with a water circuit is positioned so that so that it heats as much space as possibleThis will reduce heat loss and lower the costs of its production.

Building a stove with a water heating boiler with your own hands

Construction start with the foundation. Its lower part is filled with concrete, and the upper part is laid with bricks. Then the masonry begins. The first row is laid dry, and then - on the mortar. In this case, the masonry is carried out from the walls to the middle.

During the laying process, a heat exchanger is installed in the firebox, and the pipes coming from it are distributed throughout the body up to the point of entry/exit of communications. When external communications are installed, water is introduced into the circuit and the system is tested for leaks. If the test is successful, the furnace with a water circuit is considered ready for use.

Difficulties in construction and adjustment

The main difficulty in building furnaces with a water circuit is their integration into the existing building layout. You have to look for a convenient place in it, and then adapt it to the operating conditions of the stove.

If you plan the design of the system in the future at the stage of building design, you will be able to calculate all the nuances and make the efficiency of the heating system as high as possible.

Elements of the water circuit (heat exchanger, pipes for hot water outlet and return inlet) It is better to test immediately after production and before installation.

If everything has already been built and installed, and the heat exchanger suddenly starts to leak, you will have to dismantle the masonry and disconnect the communications to eliminate the detected defect.

Another problem when building a system can arise due to pressure. The liquid moves along the water circuit under its own pressure. But it is not always enough for the coolant to get to remote areas of the room. Then comes to the rescue Electric pump for uniform heat distribution throughout all areas of the building.

Useful video

Watch a video that explains the operating principle and structure of a wood-fired brick oven with a water circuit.

An effective alternative to other OS options

It is known that firewood is an inexhaustible resource at any time of the year. Thanks to this, a stove with a water circuit successfully plays the role of a solid fuel boiler in a private houseIts operation can become a good alternative to other heating system options.

But to get the most benefit, It is necessary to comply with the conditions of safe operation.

Thus, experts do not recommend lighting a fire if there is no coolant in the pipes. In case of year-round use of the stove It is better to add antifreeze to its systemAnd in case of failure in winter, it is better to have another backup heating option in the house.

Comments