Just one little touch missing! How to choose paint for a bathhouse iron stove

Almost every suburban area in our country has a bathhouse.

The most important part of its construction is the installation of the stove.

So that it lasts as long as possible under the influence of high temperatures And high humidity, requires processing, including using special paints.

Content

- Peculiarities of choosing paint materials

- Requirements for paints for iron bath stoves

- Types of paints and their differences from each other

- Some recommendations for choosing materials for painting

- How to paint a brick oven?

- Heat-resistant and moisture-resistant paints for metal stoves

- Useful video

- Conclusion

- Comments (5 opinions)

Peculiarities of choosing paint materials

What type of paint to choose depends on the material from which the sauna stove is made.

If we are talking about a brick oven, then here the coating is used chalk, lime or certain types of paint.

To improve heat transfer, oil paint or enamel is used, which can withstand high temperatures.

More often, metal stoves are installed in bathhouses, which also require protection from corrosion.

Effective protection against corrosion is:

- bluing;

- painting with a special composition.

Bluing is the most effective, but it takes a lot of time. It can be accelerated if the device is heated uniformly during the process of coating the metal with the solution. up to 150-200 degreesThis method is not available to everyone, so they often resort to treatment with special paints.

Reference. The coloring is the most common method for finishing the surface of the oven.

Requirements for paints for iron bath stoves

A sauna stove differs from a regular fireplace in that in this case it is made of metal There are a number of negative factors constantly in play, both from within and from without:

- cold and hot water;

- steam fumes;

- high humidity in the room;

- high temperatures due to burning wood or coal.

As for the material from which the device is made, it is usually taken stainless steelBut even in this case, it is necessary to cover it with a special paint composition to increase its service life.

The main factors to consider when choosing a paint coating:

- resistance to constant temperature changes;

- corrosion protection;

- water-repellent properties of paint;

- low toxicity.

Attention! You shouldn't buy paint from a dubious manufacturer, which standard properties are not specified And composition of componentsBuying such a fake may result in the repair of the stove.

Heat resistance

Regular exposure to high temperatures is one of the most important characteristics to consider when choosing a coating. Product certificates must include maximum possible heating temperatures.

Protection against metal corrosion

There are special paint compositions, resistant not only to high but also to low temperatures, which is an undoubted plus.

After all, the stove is not fired every day, so it is advisable to take this factor into account when choosing a protective coating for the winter period.

When heating the oven the metal expands, therefore it is desirable that the paint components in the form of special additives significantly increase the service life of the oven.

Important! The usual paint composition can withstand temperatures up to 80 degrees, and the heating of the sauna stove can reach 200 and more, take this into account when choosing a paint coating.

Water-repellent properties

Constant exposure to steam, cold and hot water, alternating heating of the stove, especially in the steam room of the bathhouse, greatly affects the strength of the metal. Therefore Moisture resistance is the most important characteristic when selecting paint.

Safety of the composition

High temperature, acting on the paint, provokes release of toxic fumes, so you should choose only high-quality and certified paints and varnishes. The absence of a certificate may threaten health deterioration or poisoning.

Types of paints and their differences from each other

You can use different paints to apply a protective coating:

- water-based acrylic;

- organosilicon;

- polyurethane.

Water-based acrylic The paint material is very convenient and affordable. The downside is that it can only be used for stoves located in rooms with low humidity, so this option is not suitable for saunas.

Photo 1. Can of white water-based acrylic paint. Manufacturer "Stroitel".

Polyurethane paints more heat-resistant and can withstand heat up to 600 degrees, it all depends on the components and additives in the paint. Study the composition in detail. Please note that when heated, polyurethane mixtures can change color.

The most environmentally friendly and durable are considered to be organosilicon paint and varnish enamels. They are able to withstand temperature conditions. up to 800 degrees. There are no toxic substances in the composition, so their use is safe. The only downside is the high cost.

Some recommendations for choosing materials for painting

In order not to make a mistake when choosing a paint coating for the stove, carefully study the composition. Resistance to high temperatures is achieved through the following components:

- silicone;

- other components containing silicon.

During heating, the paint changes into a strong film, becoming excellent shield against rust.

How to paint a brick oven?

For painting brick sauna stoves, it is best and most environmentally friendly to use lime or chalk. It has a lower percentage of toxicity, but requires regular maintenance. In addition, over time, the finish becomes covered with small cracks.

You can also use oil compositions or enamel they will significantly increase the service life of the device, but during the initial heating they can release some toxic substances into the air. Today, in specialized stores you can find paint compositions, specially designed for processing sauna stoves:

- heat-resistant enamels that can withstand temperatures up to 800 degrees;

- moisture-proof varnishes for external treatment of a brick stove, for example, KO - 815, KO - 85.

Photo 2. Can of heat-resistant varnish brand KO-85. Used as a protective coating. Manufacturer "Certa".

As for the color range, the choice is usually between black, gray and silver shades.

Heat-resistant and moisture-resistant paints for metal stoves

When choosing a paint composition for a metal device, it is important to consider heat resistance and moisture protection. The most common compositions used to coat devices:

- KO - 8101. Warranty for this composition up to 15 years. The type of paint is available at an affordable price.

- Varnish KO - 85 based on organosilicon compounds (OSC). And although the advantages of the material include high resistance to rust and moisture, the maximum temperature withstood by the composition is 250 degrees. This may not be enough.

- Enamel KO - 8111. High quality paint guarantees protection from all kinds of corrosive factors. The composition is environmentally friendly. Another plus is a large selection of shades.

- OS - 82 - OZT or heat-resistant "CERTA"This type is extremely popular among builders due to its high level of resistance to temperature changes.

Photo 3. Two cans and a spray can of heat-resistant enamel "Certa". Withstands temperatures up to 650 degrees.

- Another heat-resistant composition is considered to be Enamel KO - 8222, the coating can withstand up to 800 degrees.

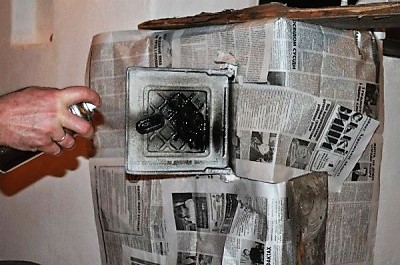

Important! Before you start painting, you should first clean the surface of the iron stove, removing all debris, this gives the coating will adhere better.

Useful video

Watch the video, which demonstrates the process of painting a sauna stove, and tells you what materials are needed for this.

Conclusion

The variety of paint coating types helps to select the appropriate composition for each specific case. It is important to consider the affordability of the price, but not at the expense of the final result. Study the composition carefully, written either on the can of paint itself or in the documentation attached to it. If you carefully approach the protection of the stove surface, then Long service life is guaranteed.

You can choose an alternative option for processing the device using the following brands: Varnish KO, Enamel KO, OS - 82 - OZT or heat-resistant "CETRA".

They significantly increase service life, guaranteeing protection from all kinds of harmful factors.

It is up to you to decide how to protect a metal sauna stove, but it is important to follow all technical rules.

Comments

The smell mixed with steam - we almost got carbon monoxide poisoning! Then my head was just splitting terribly! And after a month of airing the smell disappeared. So take the paint! It simply renewed our old rusty stove! And don't be afraid of the smell, it goes away.

- 3 cans of "Certa";

- bank "Certa-Patina";

- brush, palette, gloves;

The rust was removed with sandpaper. The surface that could not be cleaned was treated with "Ecocin-P". I also degreased it with solvent R-021. Before applying, I shook the can for 4 minutes. First, hard-to-reach places, welds, and then everything else. The painting was done in 3 layers. I am 100% satisfied with the result.