It All Starts With the Foundation: How to Build a Solid Base for a BBQ Oven

Cooking outdoors is a must-do for any family and friend getaway.

When going on a picnic, people usually make do with improvised means or folding devices brought with them, but relaxing at a summer cottage or in your own home requires the presence of a stationary platform or gazebo.

The presence of an open fire, the use of many different objects and devices dictate their requirements for the equipment of the place for preparing your favorite dishes - fire safety requirements, the possibility of supplying water, an electric cable, etc. The best option is to build a special brick oven, which will require reliable and durable foundation - foundation.

Purpose and types of foundation for a brick oven

There are many different designs of barbecue ovens. Safety requirements, designed to prevent the occurrence of a fire, require that the stove be placed no closer than 10 meters away from wooden buildings, regardless of whether they are yours or your neighbors’.

Some limit themselves to building a small oven, while others consider it correct to build a small complex under a canopy or a gazebo. In any case, preliminary laying of the foundation will be required - supporting base.

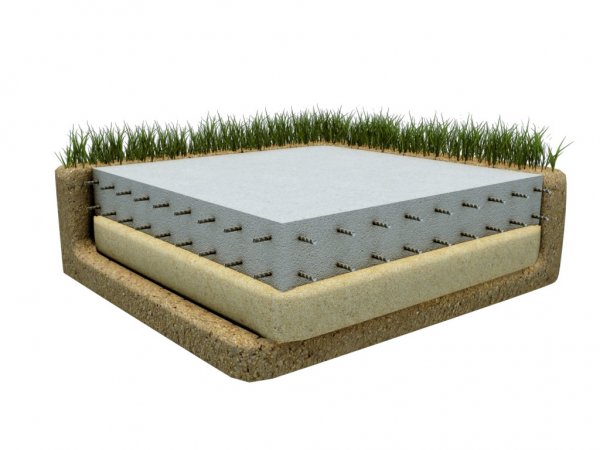

Photo 1. Slab foundation in section. It is characterized by a large consumption of concrete and reinforcement.

Size the future building is of great importance because it determines the bearing capacity foundation. The size also depends on type of foundation. The following options can be applied:

- Slab (monolithic) foundation. It is a solid slab of reinforced concrete, poured on a prepared cushion of sand and gravel mixture and river sand. It requires a significant amount of excavation work.

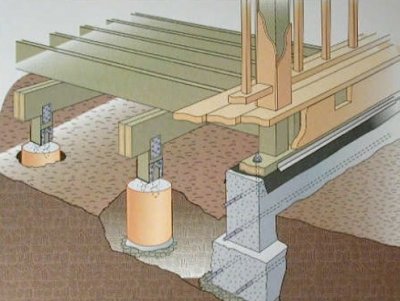

- Pile. It is used on complex soils with a high level of groundwater. There are several options for pile foundations, from the simplest columnar to bored. There are also screw piles, which can be used almost everywhere. The size of the excavation work varies from medium to almost zero.

- Ribbon. The most common type of foundation, used for most buildings. For a barbecue oven, it is convenient because it can be reinforced under the oven itself without unnecessary material costs, as is the case with slab foundations. Excavation work corresponds to the size of the trench.

Important! Of all the options, the most accessible seems to be a foundation on screw piles. Does not require preliminary soil treatment, can be used even on uneven ground, piles are screwed in manually, which means that the work can be done independently.

How to choose and prepare a place?

The type and size of the foundation are determined dimensions of the site under the barbecue, which, in turn, depend on the size of the stove, the number of people, the direction of the winds and other factors. If you plan to create a gazebo, inside which there will be a brick stove, a work table and a dining table, then the foundation corresponds to the contours of this gazebo with reinforcement in the place where the stove is laid. Let's consider the most difficult option:

- The site is selected based on the requirements for distance from wooden buildings and the prevailing wind direction.

- The site is planned, is being removed upper fertile layer of earth.

- In production backfilling the cushion with sand and gravel mixture.

- Backfill layers of river sand.

- Construction of formwork, inside which the reinforcement frame is knitted.

- Pouring a slab foundation, holding until the concrete has completely hardened.

The backfill is required to create a permeable layer that will absorb rain or melt water. This option is good in the presence of heaving soils, which have seasonal shifts due to changes in groundwater levels. Slab foundation as if “floating” on the surface of unstable soil.

When using pile (pile-screw) foundation the platform hangs above the ground, which facilitates drying and greater durability of the material. The piles are tied supporting belt - grillage, which serves as a support for the concrete platform. The absence of contact with the soil, eliminating capillary moisture suction, the support of the piles on dense soil layers make this option quite successful, especially since no basement is usually required.

Strip foundation — is a trench with formwork and a reinforcement frame placed inside, into which concrete is poured. The trench must be deeper than the soil freezing level, otherwise the tape may be torn or broken during seasonal movements. This condition may be excessively difficult for small furnaces, but for large structures the method is good and quite economical.

The final choice of foundation is made after the survey. soil conditions, making a decision about the size and design of the site and the stove itself and financial opportunities.

Making a foundation for a barbecue with your own hands

The work is divided into several conditional stages:

- Preparation project;

- acquisition materials;

- production of work.

The most important part is the calculation part - project creation, since the functionality of the foundation and the durability of the entire structure depend on it.

For building a gazebo not required creations heavy massive walls, the main load from the stove and from the canopy or roof of the building. To calculate such a foundation, you can use an online calculator, of which there are many on the Internet.

To achieve greater accuracy of calculations, it is best to duplicate the project on several sites. Let's look at an example.

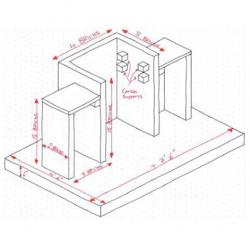

It is planned to build barbecue gazebo measuring 3 by 4 meters with the stove located at the end edge. The gazebo is of a semi-open type, foundation - strip shallow, rectangular in shape (a separate one is needed for the stove).

The point is that the movements due to frost heaving are compensated by the sand layer, which does not retain water and does not change its dimensions when it freezes. Therefore, the foundation strip remains dry and is not subject to heaving loads, and a large depth of laying the strip is not required. To ensure of sufficient strength the base will require pouring the tape with maximum thickness 30-40 cm, height 70 cm (taking into account the visible part).

A separate foundation is made for the furnace, which has no mechanical connection with the tape. The dimensions of the foundation for the furnace directly depend on its design, composition and size. In our case, a slab is accepted 2 by 1 meter thickness 20 cm.

Attention! The lack of mechanical connection is explained by different load on the foundation. The gazebo and the stove will have a certain pressure on the ground and shrinkage. The difference in loads may cause destruction a solid foundation, and individually they will respond more flexibly to changing external conditions.

Approximate cost estimate

Materials, the dimensions required for laying the foundation 3 by 4 and under the stove:

- Concrete. It will be required 3.5 m3 on tape and 0.4 m3. Total acceptedm 4 m3 concrete. Cost — 10000 RUR.

- Boards trimmed. Required 1 m3 edged board thickness 40 mm. Price 6000 RUR.

- ReinforcementA rod with a diameter of 10 mm. Necessary 60 m on tape and 36 on the stove under the oven. Cost — 2700 RUR.

Total cost is 10000+6000+2700= 18700 RUR. It is also necessary to take into account overhead costs - transportation, loading, etc. The total cost of the foundation, provided that the work is done by yourself, can be from 20,000 RUR.

Photo 2: Always clamp the board to your work surface before cutting it.

Necessary tools

You will need the following tools:

- shovel;

- building level;

- roulette;

- manual electric saw, jigsaw;

- hammer, nails;

- Bulgarian;

- screwdriver, screws for assembling formwork.

List of tools May be significantly expanded based on the capabilities and plans of the builder.

Work order

- It is planned platform, trees are uprooted (if any), the top fertile layer is removed.

- In production markup, using pegs and stretched cords the contours of the trench are being drawn.

- Digging trench 50-60 cm deep. Its dimensions by 20 cm on each side more than the calculated perimeter of the gazebo walls. The reserve is needed to accommodate the formwork and ease of work during pouring.

- The bottom of the trench is filled with a layer of sand about 20 cm thick with water pouring for compaction.

- Under construction formwork height 20-30 cm above ground level.

- Reinforcement is placed inside the formwork frame from reinforcing steel rods 10 mm thick. The reinforcement serves to strengthen the concrete strip under tensile loads to which concrete is unstable. The frame can be connected for welding or bound with soft annealed wire. The second method is considered more preferable, but if the building is small (as in our case), the reinforcement can be welded.

- Internal walls of formwork covered with roofing felt to ensure waterproofing of the foundation strip. The strips of roofing felt are laid with an overlap. Alternatively, you can waterproof the strip after the concrete has hardened and the formwork has been removed. This procedure will prevent the strip from getting wet from rain or melt water.

- Filling tapes are produced concrete, delivered ready-mixed or mixed on site. Given the location of the site, it is assumed that the mixer's access to the trench is difficult or impossible. Since the trench is small, the concrete can be mixed independently using a concrete mixer.

- Composition of concrete includes 1 part cement to 3 parts sand and gravel mixture. The mixture is diluted with water and thoroughly mixed until a homogeneous mass is formed. The viscosity should approximately correspond to the consistency of sour cream.

- Ideally, the filling should be done at one moment. In practice, this is unachievable, but it is necessary to strive for the fastest possible pouring. This will allow achieving the same concrete parameters along the entire length of the strip.

Photo 3. You can smooth out concrete poured into the form using a special tool or a wooden board.

Nuances to consider

Low mass furnace (up to 500 kg) can be built without foundationIn this case, it is necessary to take into account the possibility of additions or changes to the furnace design, which may subsequently require laying a foundation.

When choosing a location, you should avoid the presence of trees, hanging over the gazebo.

The foundation device can be somewhat simplified if the site is prepared lay a reinforced concrete slab. This eliminates the stages of pouring and mixing concrete mortar, and reduces the time it takes for the base to dry.

Instead of a summary

Building a foundation for a barbecue is an issue that is accessible to everyone independent solutions. When starting work, it is necessary to take into account possible subsequent changes and extensions that increase the load on the foundation, so it is necessary to have some safety margin. Selecting the type of foundation based on soil properties and the expected site dimensions. All calculations can be done independently or using online calculators that are convenient for this type of project.

Useful video

The video clearly explains, with photographs and diagrams, the intricacies of creating a foundation for a stove.

Comments

And is it necessary in this case to install a sand bedding layer?

Ideally, the soil is removed down to the continental layers.

The construction of a sand bedding layer is also necessary on all types of soil except sandy soils. On sandy soils, it is best to construct a bedding layer of large crushed stone.

I used broken brick instead of crushed stone. Only when adding to the solution, I sifted the broken brick through a mesh with a cell of 0.5x0.5 cm and washed it with a stream of water. The quality did not suffer at all.