Surprise your friends and acquaintances: a hot smoking smokehouse with your own hands

Hot smoked products are slightly inferior in taste to those prepared using the cold smoking method.

But they have their own significant advantage: they are many times prepare faster.

Due to this, hot smoking smokehouses are a priority for summer residents and owners of private houses.

Principles of the device of hot smoking smokehouses with a water seal

Factory-made smokehouses are good in every way: they are convenient, beautiful and well-equipped. But most of these products have one significant drawback: they are so thin metal, as far as possible for this type of device.

Manufacturers are trying to save on everything and are producing stainless steel products with maximum permissible minimum thickness. This has caused a considerable number of negative reviews, in which consumers complain that after several smoking sessions the device “leads”, and its further use becomes problematic.

Photo 1. The process of cooking fish in a smokehouse made by hand. The products are laid out on a special grate.

This is where the first rule for constructing homemade hot smoking smokehouses comes in: they must be made of metal with a thickness of not less than 2 mm.

For this you can use:

- metal barrels;

- tanks and cisterns;

- refrigerators;

- washing machines;

- deep and spacious cauldrons and braziers;

- large pots.

The peculiarity of hot smoking smokehouses is that they are heated by a source located immediately below them. This can be open fire (fire, gas) or electric stoveThere is another design option in which the firebox is connected to the smoke chamber by a very short chimney, up to 50 cm length. These are usually high-performance, large-sized, stationary smokehouses, the construction of which requires a lot of work.

Reference. Aesthetic gardeners strive to make smoking equipment as beautiful as possible beautiful and spectacular. Thus, the smoke chamber is often laid out of brick in the form of a house with a door, a window, a roof and a chimney.

Smoke exhaust — an important element of the smokehouse. Traditionally, it is made from a metal pipe with a knee. At the top of the flue there must be a damper, with the help of which the draft force is regulated. This is the second rule of the device of hot smoking smokehouses.

The third is that lattice, on which the food is placed, should be at a distance from the bottom of the chamber that is sufficient for the smoke to cool slightly, otherwise it will not be smoking, but boiling.

The optimal height of the lower tier of grates from the bottom is 10-15 cmThis must be taken into account when choosing a product for a smoke chamber.

Smokehouses are often equipped with a water seal. It is a trough located along the perimeter of the metal body. Before smoking, the trough is filled with water, which prevents the spread of strong odors that form during smoking food.

The right smokehouse from a tank

A metal tank is ideal for a quick and dirty portable smokehouse. capacity from 20 l. It needs to be installed on a specific brick platform, which is built in the form of two opposite walls. A fire is lit between them.

To make a smokehouse, a layer of shavings is poured onto the bottom of the tank. 3-5 cm. A grate of such a diameter is installed inside that it is at a distance 10-15 cm from the bottom.

For this purpose, legs can be welded to the grate (or otherwise attached). If it is not possible to make legs, they can be embedded into the walls of the tank. in 3-4 places Bolts are screwed in around the circumference. The grille is installed on them.

The second and third tiers can be made in a similar manner.

A hole is punched or drilled into the tank lid several small holes for removing smoke and steam.

Reference. Ash from sawdust and burnt shavings are excellent fertilizer for beds, so hot smoking is waste-free production.

A device from a barrel for smoking meat, fish, lard

Eat several options making smokehouses from metal barrels. But you can go the other way: make two portable smokehouses from one barrel. One for fish, the other for meat.

This method is suitable for those who do not want to put as many products as possible in one go, but want to get excellent quality.

Regardless of whether the whole barrel is used, The design of the smokehouse remains unchanged.

Attention! A smokehouse is a fire-hazardous structure that requires close attention, so you need to choose a place for its installation with the utmost care. The main requirement for a place for a fireplace is protection from gusts of wind.

Materials for manufacturing:

- rods (rebar will do);

- gratings for sawdust and products (can be made from #4 electrodes or thick wire);

- pieces of metal pipe diameter 15-25 mm and length 3-5 cm (3 pcs);

- grease tray (you can use foil folded into a plate shape with sides);

- door metal hinge;

- metal latch for a door (any type of bolt);

- metal mesh type "chain-link";

- bricks (8 pcs);

- fasteners: self-tapping screws for metal and bolts.

Manufacturing stages

Step 1. Preparing the barrel.

The container is washed to get rid of the smell. Car wash products are very helpful. If you have a mini-wash, use it too.

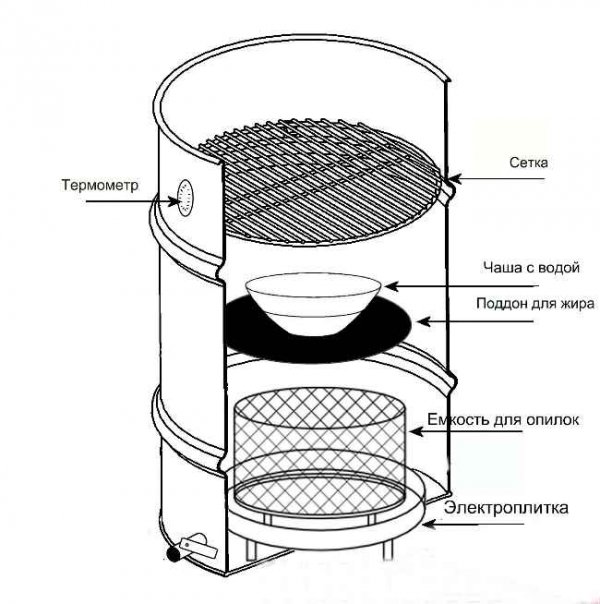

Photo 2. Diagram of the device of a hot smoking smokehouse with an electric heating device from a barrel. Several tiers for cooking can be installed inside.

Step 2. Making the lid.

From the top of the barrel they recede downwards 5-6 cm and draw a line around the circumference of the container. Using a grinder and a metal disk, cut off the marked part. It usually has two holes: a large one and a small one. The first one is left closed, and the second one is opened. The side walls are cut with a grinder every 1-1.5 cm. Slightly bend this "herringbone" outward. This way, a tight fit and adhesion of the lid to the smoking chamber is achieved.

Step 3. Making the door.

At the height 5-7 cm from the bottom of the barrel draw a rectangle of such a size that it is enough to remove the ash and put the shavings in and cut it out with a grinder. On the right, drill two holes and attach one part of the door hinge. Try the door on the barrel, find the attachment points for the hinge and attach it. Screw the latch in the right place.

Step 4. Making a stand for the pallet.

Inside the barrel, in three places equidistant from each other, pieces of pipe are welded to the bottom (or secured with metal screws).

Step 5. Making grates for products.

Place the lid on the metal mesh with the herringbone pattern facing up and draw a circle around it with a marker, then cut it out with metal scissors or saw it with a grinder.

Step 6. Installation of stops for metal gratings.

The internal equipment of the smokehouse usually consists of several tiers. The considerable height of the barrel allows you to make 3-4 tiers. This will require the appropriate number of grates.

For each tier they construct 3-4 supports from bolts with a cross-section of 10 mmFirst, holes are drilled in the required places with a drill of the required diameter, then bolts are inserted and secured with nuts from the inside of the barrel.

Step 7. Construction of the firebox (hearth).

From 8 bricks are laid out 4 walls that are connected to each other, each of which must be a height of 2 bricks.

Step 8. Making a support for the barrel.

In order for the smokehouse to be raised above the hearth, supports are needed. Here the master has room for imagination. It can be welded to the bottom 3-4 legs, you can build two brick walls in the immediate vicinity of the fireplace.

Step 9. Installation of smoke exhaust.

Since there is a hole in the barrel lid, it will serve as a smoke exhaust. To regulate the draft, it is simply covered with a metal plate or stone. But you can also improve the smokehouse: weld a hollow tube to this hole.

Photos of finished smokehouses

Photo 3. Factory-made cylindrical smokehouse made of stainless steel.

Photo 4. The smoking process in a smokehouse with a water seal. In the upper part of the device there is a smoke outlet from which smoke comes out during cooking.

Photo 5. Smokehouse during cooking. The grill is used as a firebox.

Useful video

Watch the video, which shows in detail the process of making a hot smoking smokehouse with your own hands.

Comments

And if the product is heated strongly, it will simply burn in this pipe - the smokehouse, and not get smoked. Or am I wrong?