Smoking at home without unwanted odors: DIY smokehouse with a water seal

The water seal is a special a trough built into the perimeter of the bodyBefore heating the smokehouse, it is filled with water.

This element is intended for sealing of evaporation and odorIt prevents the leakage of smoke that accumulates inside the housing.

Design of a smokehouse with a water seal, drawings

This unit has some differences from the standard one.

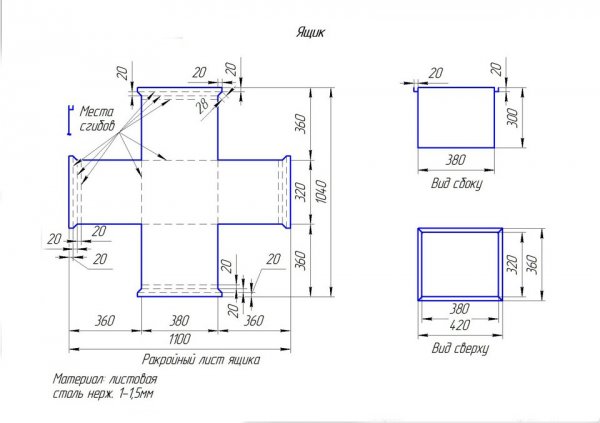

Photo 1. Drawing of a smokehouse with a water seal indicating the dimensions of the device: cutting sheet of the box, side and top view.

It includes:

- Metal box, equipped with a sealed lid.

- Flat pallet, located at the bottom of the smokehouse and designed to collect fat.

- Compact grilles, on which products are placed during the smoking process.

- Water seal, which is a special element of such a device, representing a groove intended for a lid. Water is poured into it. It is made part of the smokehouse by welding.

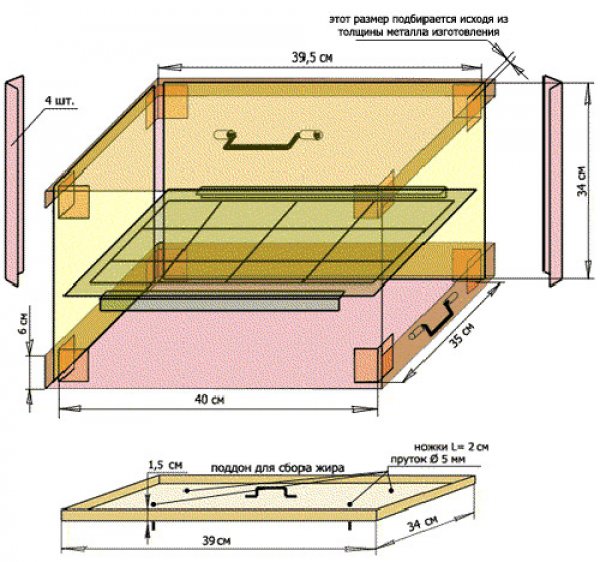

Photo 2. Drawing of a smokehouse with a water seal. It shows the structure of the smoking chamber, grate, fat collection tray, and device cover.

Operating principle

The water seal is made of stainless steel. 1.5 mm thick. With its help, you can completely seal the smokehouse. The element works thanks to water, which does not allow smoke masses to leave the body through the gaps between the lid and the wall, due to which it becomes possible to use the smokehouse for its intended purpose in a house or enclosed spaceThe water seal also acts as a stiffener.

Preparing for assembly

To make the device yourself, you will need:

- Stainless steel sheet size 150×100 mmIts thickness should not be less 2 mm.

- Steel wire diameter 10 mm And 20 cm long. It will serve as the basis for making the handle.

- Stainless steel wire diameter 3 and 5 mmThe thick material will be used to construct the lattice posts, and the thin material will be used for the main part.

- A piece of iron pipeline diameter 10 mm And 5 cm long.

Once the necessary materials have been collected, you should prepare the tools:

- A welding machine required to connect structural elements together.

- Drill.

- Angle grinder.

- Mallet.

- Hammer.

- A ruler.

- A pencil is needed for applying markings.

If you have the listed tools at hand, the assembly will proceed without delays and difficulties.

Attention! When choosing materials, special attention should be paid thickness of iron sheets. Iron that is too thin burns out quickly, and the smokehouse will most likely fail already. a few days after productionIf you don't want to start the assembly from scratch, it's better to choose the appropriate hardware in advance.

The process of making the device yourself

To make a quality smokehouse, follow a certain algorithm:

- They determine which one exactly type of device will be produced. If it is decided to make a device equipped with a water seal, then it will be possible to cook at home or in closed rooms with its help. A water seal is added to the design when they want to ensure reliable sealing and ease of opening and closing the lid.

- The body is being manufacturedIt is a metal box measuring 500×300×300 mm. Rectangles are cut out of metal and fastened together using drop welding. You can also cut a cross out of iron and bend the side elements upward, after which you need to weld the edges.

- They are making a firebox, which is located at the bottom of the smokehouse (or under it). The open fire is separated from the smoked products by a metal sheet on which sawdust is laid out, producing smoke during smoldering.

- Making a grill for meat, using stainless steel wire. To obtain the desired product, cut off a piece of length 45 cm and bend it letter "P". Then take the wire and cut it off. 9 fragments of 9 cm eachThe resulting rods are welded to the base.

- They make a tray to collect fatTo obtain it, you will need a steel sheet of size 52×32 cm. At the same time 2 cm Bend upwards on each side. This is how you get sides.

Photo 3. Smokehouse with a water seal, made of metal. All elements of the design are visible: the body, grates, lid.

If you follow the described algorithm, you can obtain components that only need to be assembled.

Assembling a Home Smokehouse

Once all the components are ready, you need to do the following:

- Weld steel strips onto the inside of the body, which will act as supports for the grates. On the lid a special pipe is installed, designed to remove smoke masses. Its diameter is 1 cm.

- Install grates, made of stainless steel (the products that will be smoked are placed on them). Below a removable bottom is mounted, which acts as a tray for collecting fat. It is equipped with special knives in such a way that a cavity appears between the lower part of the body and its plane.

- Close the smoker with an airtight lid., the sides of which are directed downwards. To ensure complete sealing, the water seal is filled with water.

What problems may arise during manufacturing?

There are situations when during smoking fish or meat start to stick to the grates, and solving such a problem takes some time.

Photo 4. The finished smokehouse with a water seal, disassembled: a metal box, two grates, a tray for collecting fat.

This problem can be avoided if you use the following materials to make the gratings at the assembly stage: stainless steel wire.

If the assembly was done poorly, a problem arises in which the smoldering fuel in the smoking chamber starts to burn. This means that the seal is broken and air has access to the inside of the housingIn such a situation, the entire unit is checked and unnecessary holes are sealed by welding.

Sometimes the water from the water seal evaporates too quickly. This happens if the mentioned element is welded from the inside of the body. To avoid this, The water seal is placed outside metal box. If everything is done correctly, there is no need to frequently add new water to the gutter.

Checking the water seal

To check how efficiently an element works, water is poured into the trough and a fire is lit.

If smoke appears not only from the pipe specially designed for it, this will indicate an imperfect design.

In such a situation, further development is carried out.

Pros and cons

The described design has both positive and negative sides.

Its advantages:

- A smokehouse equipped with such a chute is ideal Suitable for use in a city apartment.

- To make such a device, stainless steel is used, which has good anti-corrosion properties. It looks beautiful and does not require careful maintenance.

- The walls are easy to clean from carbon deposits from the inside.

As for the disadvantages, the weight of such a smokehouse is quite large. Usually it weighs from 12 to 20 kgIt cannot be used as a portable device.

Useful video

Watch the video, which shows step by step the process of making a smokehouse with a water seal.

I made the corner myself from a 50 mm wide stainless steel strip. The corner turned out to be: one 15 mm shelf – I welded it to the body. The 20 mm high shelf allows pouring a fairly high layer of water.