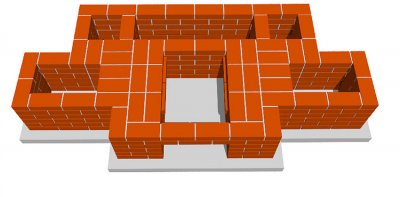

Two in one - a stove with a barbecue and a smokehouse made of bricks

Brick smokehouses with a built-in grill for frying meat are suitable for construction on the territory of private houses and summer cottages.

Such structures allow you to save space on the site and prepare fried and smoked dishes at the same time, making a fire in one firebox.

Content

Smokehouse and barbecue made of bricks in one device, drawings

There are the following main types of brick smokehouse ovens with a built-in barbecue:

- barbecue smokehouse for cold smoking;

- barbecue smokehouse for hot smoking;

- combined buildings.

The main elements of this structure are:

- firebox;

- smoking chamber with frames;

- barbecue grill;

- chimney.

The chimney has a winding structure, going around the smoking frame from below and from the side. Such a design is necessary for smoke cooling, since when wood burns, its temperature is significantly higher than when smoking wood smolders.

The smoking chamber has grates located in several tiers, which allows you to smoke a large amount of product.

ReferenceThe disadvantage of this design is the need to transfer some of the coals to the grill section or to light a separate fire in it.

This design consists of several parts:

- chimney;

- barbecue surface;

- two fireboxes - for the grill and for smoking;

- hanging smoking chamber.

The smoking chamber for products is located at a height here. 1-1.5 meters and is intended for cooking fish or meat cold methodThe products are hung on special hooks without grates.

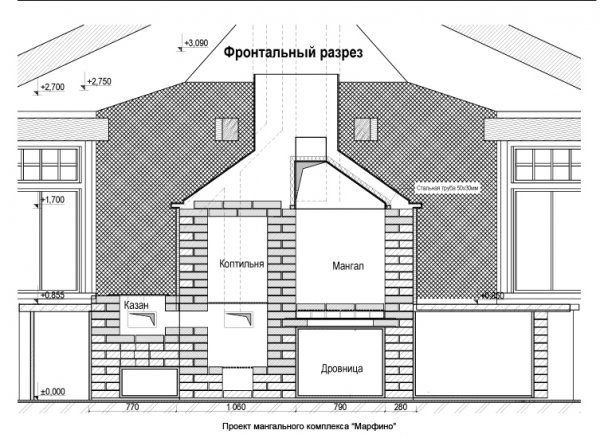

Photo 1. Drawing of a barbecue with a brick smokehouse in a frontal section. The device also has a woodpile and a cauldron.

If it is necessary to simultaneously smoke and cook dishes on the grill, the upper firebox is lit, the lower one is used only for smoking. In this case, the surface of the upper firebox is used as a smoke generator, crushed wood is smoldering on it alder or willow shavings for better taste of the product.

Such barbecues with a smokehouse are very similar to fireplaces. In fact, that is what they are, but their main purpose is not heating the room, but cooking.

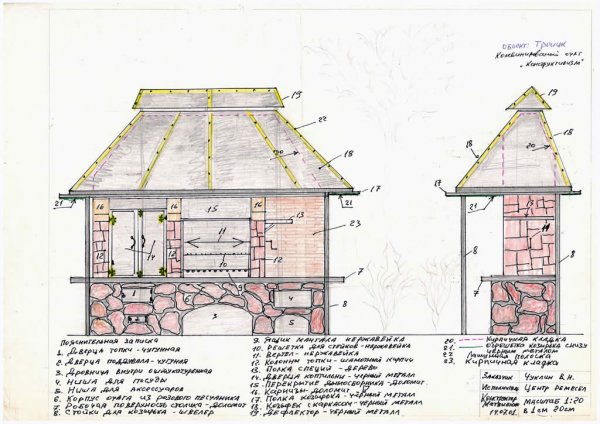

Photo 2. Drawing of a barbecue with a smokehouse made of bricks with parts of the structure indicated. Front and side views.

The sizes of the finished structures vary from 1x1.5 meters to 1.5x3 meters. They depend on the relative position of the barbecue part, firebox and chimney, as well as the presence of additional design elements, for example, stove burners or places for drying firewood.

How to make an outdoor stove with your own hands? Preparation for work

Preparatory work consists of choosing a project and preparing the necessary tools and materials. When choosing a project It is important to consider the following points:

- availability of space on the site;

- preferred smoking method;

- presence of additional elements;

- outdoor or indoor placement;

- ease of approach;

- fire safety requirements.

After the project is selected, it is prepared and cleared. place for construction, and is also compiled list of required materials.

Attention! The purchase of consumables (bricks and cement) should be carried out in quantities exceeding the calculated ones. by 5-10 percent, to take into account losses due to incorrect calculations or lack of experience.

Tools and materials

The main materials for building a smokehouse will be bricks And solution for bonding them.

The bricks for the main structural elements (firebox and chimney) are selected from fire-resistant grades, manufactured in accordance with GOST 390-96. Such brands may include ША-I, ШБ-I or PB-II.

Cement mortar for bonding bricks prepared on the basis of:

- 1 part refractory cement;

- 2 parts sand;

- 1 part limestone.

Reference. Solution, bonded limestone, better withstands temperature changes in winter than a regular mixture of sand and cement.

Construction will also require the following materials and tools:

- metal frames and grids;

- steel rods;

- reinforcement;

- crushed stone;

- formwork boards and a rule;

- shovel;

- building level;

- roofing felt;

- corners and fasteners;

- circular saw and welding machine.

Wire diameter for smoke rack nets and rods should not be less than 0.8 mm, otherwise the rack will deform due to temperature and the weight of the products.

If the internal smoking chamber is made in the form of an insulated metal box, then the thickness of its walls starts from 2 mm. The thickness of the bend of the corners, to which the vertical metal part of the barbecue or smoking rack is fixed, is within the range 3-6 mm.

Step-by-step instructions for making a brick smokehouse with a barbecue

Sequence of basic actions on the construction of a smokehouse with a barbecue:

- Compilation orders — brick laying patterns.

- Filling foundation.

- Laying the main frame and chimney made of brick.

- Manufacturing and installation smoking grate.

- Installation doors and additional elements.

Before construction begins the space for the foundation is marked out in accordance with the selected project.

Ordering

If you have no experience in building such structures, it is better to use standard, already tested orderIf you want to experiment and create a unique design, you should first work with simpler smokehouses.

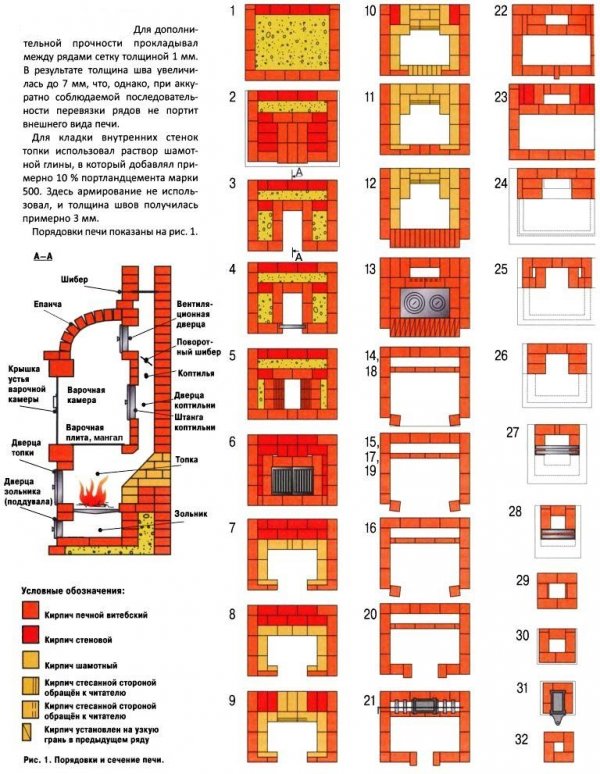

Photo 3. Diagram of the standard layout and section of a stove with a barbecue and smokehouse, made of brick.

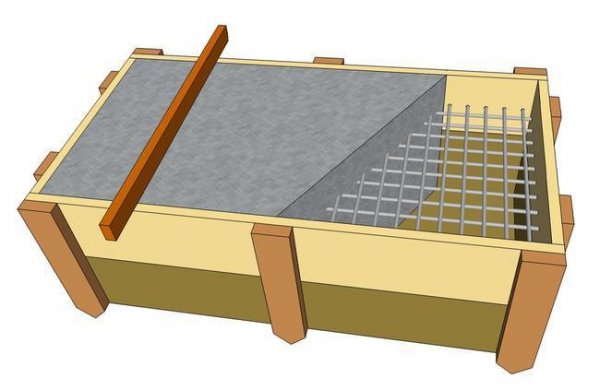

Pouring the foundation

After marking the perimeter of the building, a layer of fertile soil is removed and a hole is dug to a depth of 0.4-0.8 meters. The depth depends on soil stability And massiveness of the structure.

The walls of the pit are lined with boards as formwork so that they protrude above the edge of the pit by 10-12 cm. Formwork thickness - 15-20 mm. A layer of pebbles or crushed stone is poured onto the bottom of the dug hole, and the inner surface of the formwork is lined with roofing felt using nails with wide heads. Then the reinforcement tie for the foundation is laid.

Reference. Reinforcing bars are selected with a thickness of at least 8 mm, and the inner side of the mesh is 10-15 cm.

The pouring solution is prepared based on the following calculation:

- 1 part cement;

- 1 part fine crushed stone;

- 3 parts sand.

The solution is poured onto the prepared reinforcement tie in layers of no more than 10-15 cm, each layer dries in 24 hours, after which a new one is poured. The last layer is leveled with a straightedge, and the entire structure is covered with a waterproofing film.

Photo 4. Scheme of the foundation for the furnace: the formwork is laid out with boards, then cement is poured, separated by reinforcing bars.

Construction of the main part

Before laying bricks on the foundation, they draw contours of the bottom layer of bricks in accordance with the project and they are pulling the strings to indicate the initial horizontal level.

Important! The first layer of bricks is laid according to the drawing and not bonded with mortar, and each subsequent layer is laid overlapping for the strength of the bond.

The laying of the main structure is carried out in the following order:

- Firebox laying.

- Installation of fasteners for a smoking rack and barbecue.

- Laying the chimney.

If the structure is more than one and a half meters high, bricks are placed every 2-3 rows are laid with reinforcing ties.

Fasteners for smoking grate and grill surface welded to parts of the reinforcement and are laid at the required height in the structure. When laying the chimney part less cement mortar is used, than when laying the lower part of the structure, in order to prevent the pipe from collapsing due to the scattering of mortar.

To make the smoking grate, steel wire with a diameter of not less than 2 mm, if the smoking rack is multi-tiered, and not less than 1.5 mm with a single-tier rack.

The installation of fasteners for the grills and barbecue surface occurs at the stage of laying bricks.

Possible difficulties

When building a smokehouse, problems often arise when an inexperienced builder the following difficulties and errors:

- fragility of the fastenings of the hanging hooks and gratings;

- unevenness of masonry;

- scattering of the solution after hardening.

To avoid the fragility of the fastening of the suspended parts, it is necessary to recess them more deeply into the masonry - not less than 10 cm.

Important! To avoid uneven masonry, every two rows A building level is applied to the top layer of bricks, making adjustments if necessary.

Avoiding unevenness also helps parallel masonry all elements of the structure level by level, even if at the initial stages these elements are not connected to each other.

Reasons for crumbling of dried solution:

- use of dry bricks;

- using incorrect proportions;

- poor quality cement in the solution.

Watering the bricks with water a day before laying will prevent it from absorbing liquid from the solution and will ensure uniform drying.

Using a ready-made fireplace

You can start using the built smokehouse with a barbecue in 8-14 days after the laying is completed. These terms depend on the humidity and air temperature.

At stable rainy weather You cannot start using the smokehouse before in 2-3 weeks after the masonry is completed, otherwise the undried bonding mortar will crumble, which will lead to the destruction of the entire structure. To speed up the drying of the mortar in rainy weather, the finished structure is covered with an awning.

Useful video

Watch the video, which tells about the project of barbecue (grill) with a smokehouse made of bricks.

Comments